Method for comprehensive utilization of low-iron red mud

A technology of red mud and crystal seeds, applied in chemical instruments and methods, alkali metal compounds, alkaline earth metal silicates, etc., can solve the problems of waste of raw materials, low removal efficiency and high cost, and achieve lower sintering temperature and market application. The effect of widening and reducing the amount of calcium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

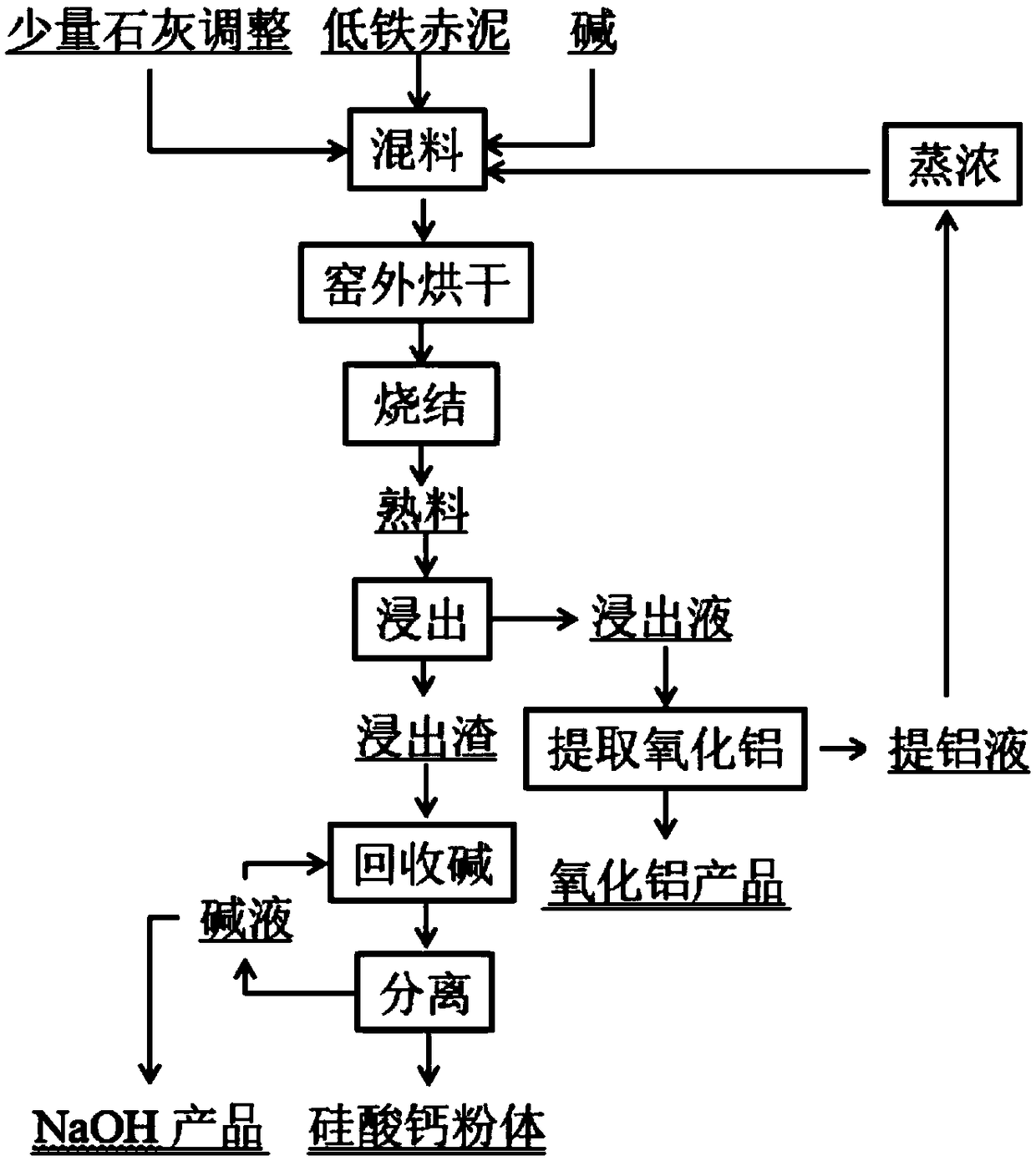

Method used

Image

Examples

Embodiment 1

[0041] This embodiment adopts Bayer process red mud, and its main chemical composition (mass percentage, wt%) is: alumina (Al 2 o 3 ) 27.85%, silicon dioxide (SiO 2 ) 24.73%, sodium oxide (Na 2 O) 5.63%, calcium oxide (CaO) 14.61%, iron oxide (Fe 2 o 3 ) 11.66%, titanium dioxide (TiO2) 5.37%, and its aluminum-silicon ratio is 1.1;

[0042] Lime and supplementary alkali are common industrial grade products; Alkali used in the present embodiment is sodium carbonate, and wherein, the amount of substance of sodium carbonate converted into the amount of substance of sodium oxide is the same.

[0043] The total amount of sodium, iron, aluminum, calcium, silicon, and titanium in each form of low-iron red mud, lime, and alkali is calculated as the number of moles of oxides, and the ingredient relationship is satisfied. The square brackets below indicate the amount of each substance. The unit is mol:

[0044] Alkali ingredients are [Na 2 O] 总 =[Na 2 O] 1 +[Na 2 O] 2 +[Na 2...

Embodiment 2

[0060] In this embodiment, the low-iron red mud is processed, and its main chemical composition (mass percentage, wt%) is: alumina (Al 2 o 3 ) 28.53%, silicon dioxide (SiO 2 )16.78%, sodium oxide (Na 2 O) 6.39%, calcium oxide (CaO) 16.34%, iron oxide (Fe 2 o 3 )8.39%, titanium dioxide (TiO 2 )5.40%, its aluminum-silicon ratio is 1.70;

[0061] Lime and supplementary caustic are both ordinary industrial grade products; caustic is sodium hydroxide, and the ingredients satisfy the following relationship:

[0062] Alkali ingredients are [Na 2 O] 总 =[Na 2 O] 1 +[Na 2 O] 2 +[Na 2 O] 3 ,

[0063] Among them: [Na 2 O] 1 =[Fe 2 o 3 ]; [Na 2 O] 2 =[Al 2 o 3 ]; [Na 2 O] 3 =X N ×[SiO 2 ],

[0064] The calcium ingredient is [CaO] 总 =[CaO] 1 +[CaO] 2 ,

[0065] Among them, [CaO] 1 =[TiO 2 ]; [CaO] 2 =X C ×[SiO 2 ],

[0066] That is: [Fe 2 o 3 ]+[Al 2 o 3 ]+X N ×[SiO 2 ]=[Na 2 O] 总 , and [CaO] 总=[TiO 2 ]+X C ×[SiO 2 ],

[0067] x N = 1.0;

...

Embodiment 3

[0077] The embodiment adopts the red mud of Bayer process, and the main chemical composition (mass percentage, wt%) is: alumina (Al 2 o 3 ) 21.30%, silicon dioxide (SiO 2 )19.43%, sodium oxide (Na 2 O) 6.43%, calcium oxide (CaO) 16.92%, iron oxide (Fe 2 o 3 ) 11.91%, titanium dioxide (TiO 2 ) 2.39%, and its aluminum-silicon ratio is 1.10;

[0078] Lime and supplementary carbon soda are common industrial grade products; carbon soda is sodium bicarbonate,

[0079] The total amount of sodium, iron, aluminum, calcium, silicon, and titanium in each form of low-iron red mud, lime, and alkali is calculated by the number of moles of oxides, and the ingredient relationship satisfies: [Fe 2 o 3 ]+[Al 2 o 3 ]+X N ×[SiO 2 ]=[Na 2 O] 总 , and [CaO] 总 =[TiO 2 ]+X C ×[SiO 2 ],

[0080] x N = 1.0;

[0081] x C = 1.5. Such as needing to process low iron 100g in the present embodiment, then need 11.96g lime, 40.27g sodium hydroxide.

[0082] according to this figure 1 A m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com