Cu-SAPO molecular sieve synthesis method, synthesized Cu-SAPO molecular sieve and application of Cu-SAPO molecular sieve

A molecular sieve, cu-sapo-34 technology, applied in molecular sieve and alkali exchange phosphate, separation method, molecular sieve catalyst and other directions, can solve the problems of generating silicon island, affecting product yield and crystallinity, etc., to achieve catalytic performance improvement, The effect of good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Synthesis of copper-containing Cu-SAPO-34 samples as copper source.

[0046] The molar ratios and crystallization conditions of each raw material are shown in Table 1, and the specific batching process is as follows:

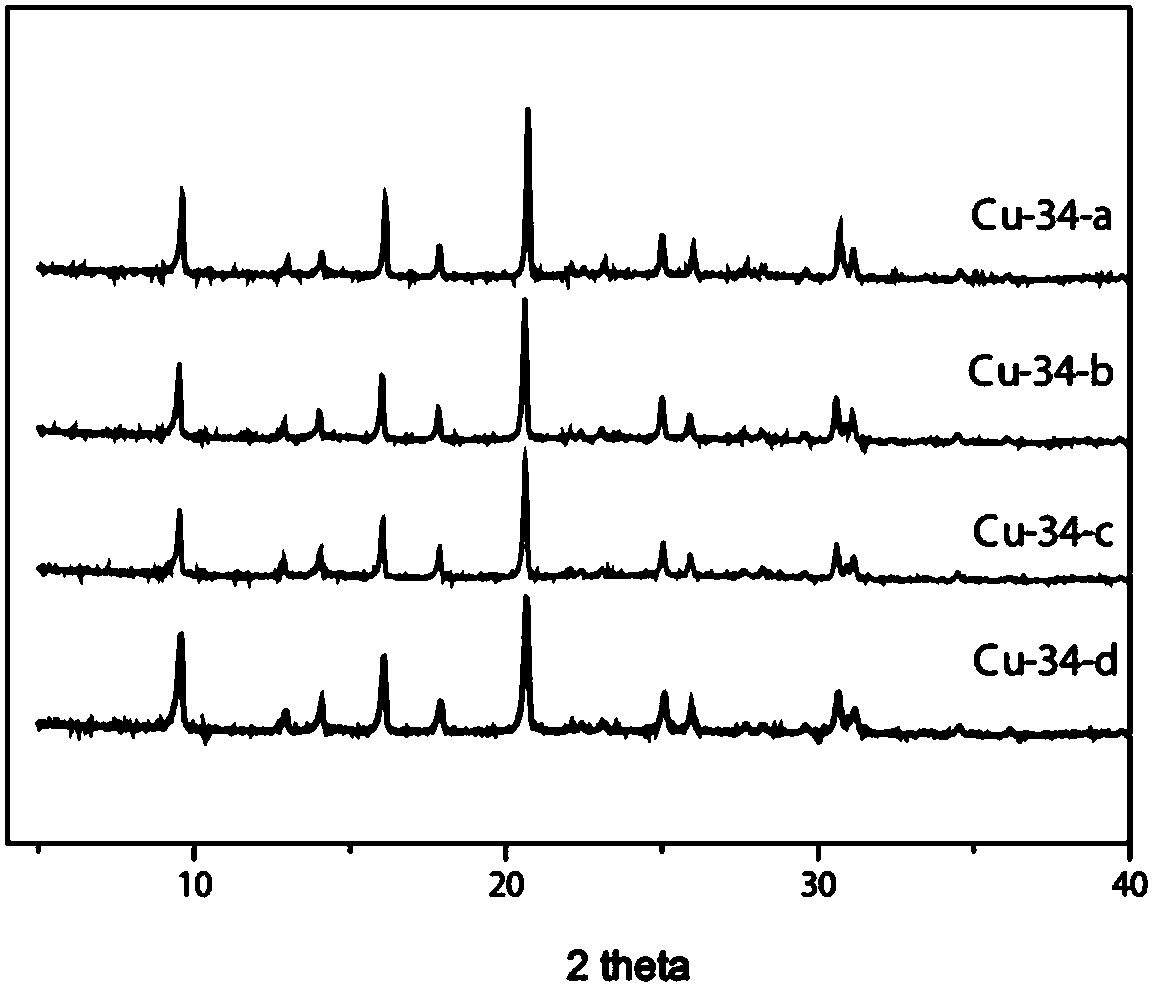

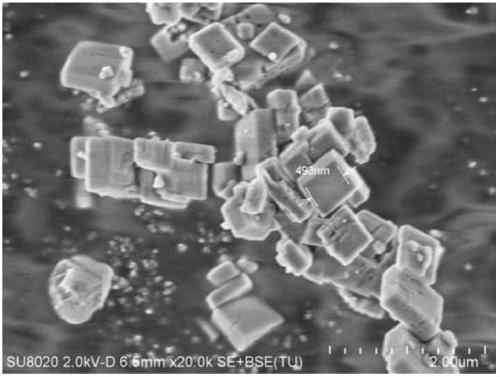

[0047] Add pseudo-boehmite (65% by weight), water, phosphoric acid (85% by weight), silica sol (31% by weight), copper sulfate pentahydrate, tetraethylenepentamine (TEPA), optional The organic template agent R1 and the SAPO-34 seed crystal were stirred evenly, then sealed, heated to 140-200°C under stirring, and crystallized for 5-24h. The solid product was centrifuged, the sample was washed with deionized water to neutrality, and after drying in the air at 120°C, the ready-to-use Cu-SAPO-34 molecular sieve (named Cu-34-x, x=a, b, c , d). The purpose of adding seed crystals in the synthesis is to reduce the particle size of the synthesized high-copper Cu-SAPO-34, so that it can better participate in the subsequent crystallization and play the role of se...

Embodiment 2~9

[0051] Embodiment 2~9: the preparation of high hydrothermal stability Cu-SAPO-34 molecular sieve product

[0052] The molar ratios and crystallization conditions of each raw material are shown in Table 2. The specific batching process is as follows:

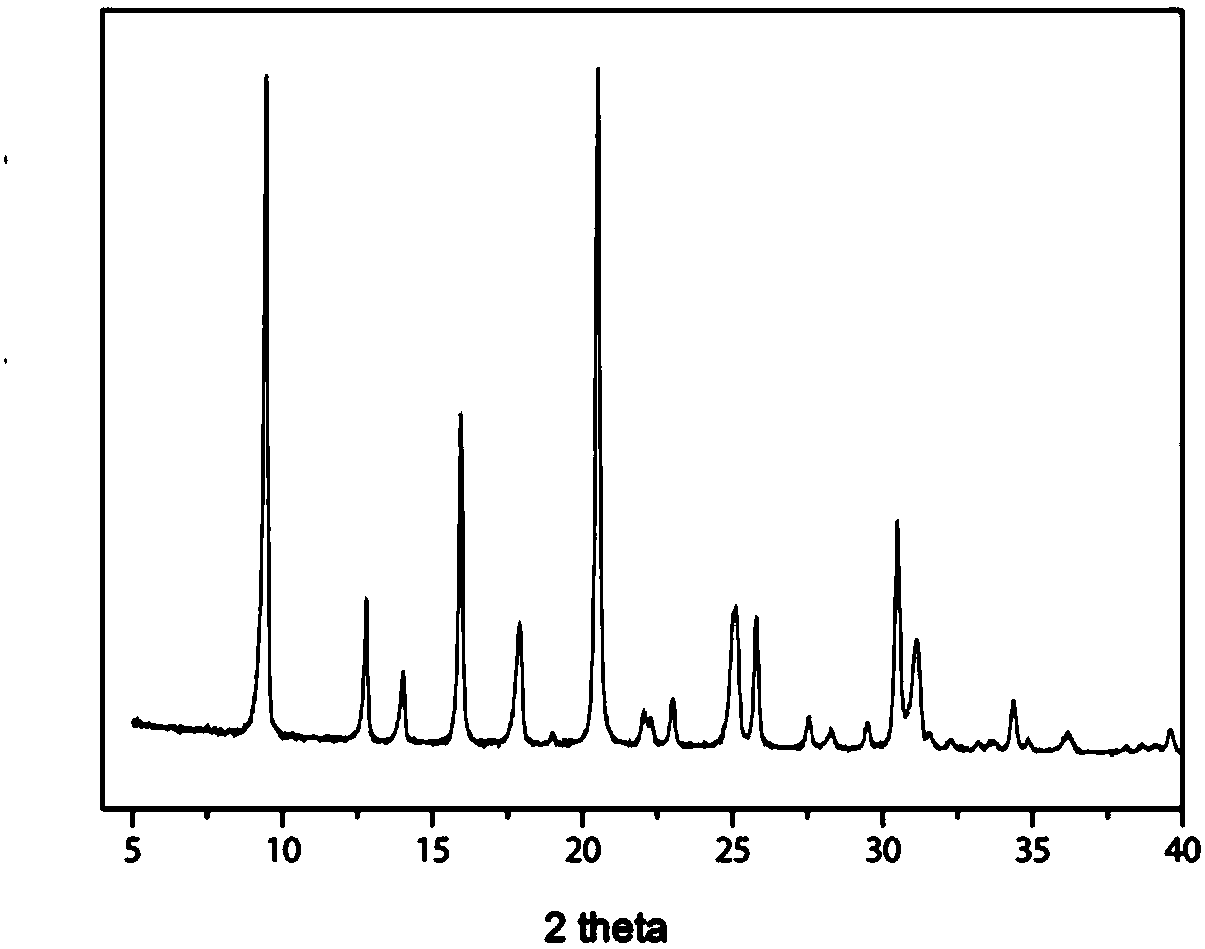

[0053] Firstly, the aluminum source is mixed and dissolved with water, and then the optional phosphorus source, silicon source and templating agent R are sequentially added thereto. To the above mixture was added the Cu-SAPO-34 sample prepared in Example 1. After stirring evenly at room temperature, the gel was transferred to a stainless steel reactor. After the reaction kettle is put into an oven, the temperature is raised to 160-200° C. for 0.5-72 hours, and the crystallization is completed. The solid product was centrifuged, washed, and dried in air at 120°C to obtain a sample of molecular sieve powder. The sample is analyzed by XRD, and the peak shape presents a typical CHA structural characteristic peak, and the XRD diff...

Embodiment 10

[0056] The samples of Examples 3, 5 and 8 were calcined at 650 °C for 2 h, and after removing the template, they were used for NH 3 Selective reduction to remove NO x Catalytic performance test of the reaction. The specific experimental process and conditions are as follows: after roasting, the sample is pressed into tablets and sieved, and 0.1 g of 60 to 80 mesh sample is weighed and mixed with 0.4 g of quartz sand (60 to 80 mesh), and loaded into a fixed bed reactor. Activate with nitrogen at 600°C for 40 minutes, then lower the temperature to 120°C to start the reaction, and raise the temperature to 550°C. The reaction raw material gas is: NO: 500ppm, NH 3 : 500ppm, O 2 : 5%, H 2 O: 5%, N 2 As the balance gas, the gas flow rate is 300mL / min. The reaction tail gas adopts the Tensor 27 instrument of Bruker Company to carry out online FTIR analysis, and the results are shown in Image 6 . It can be seen that the sample in Example 3 has low activity at a temperature bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com