Titanium alloy denture bracket and manufacturing method thereof

A manufacturing method and technology of titanium alloy, which are applied in the fields of dentistry, dental prosthesis, medical science, etc., can solve the problems of fracture of support frame, poor precision, cumbersome production of over-molding casting process, etc., and achieve high manufacturing precision, short time-consuming, The effect of wearing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further elaborated below by specific embodiment:

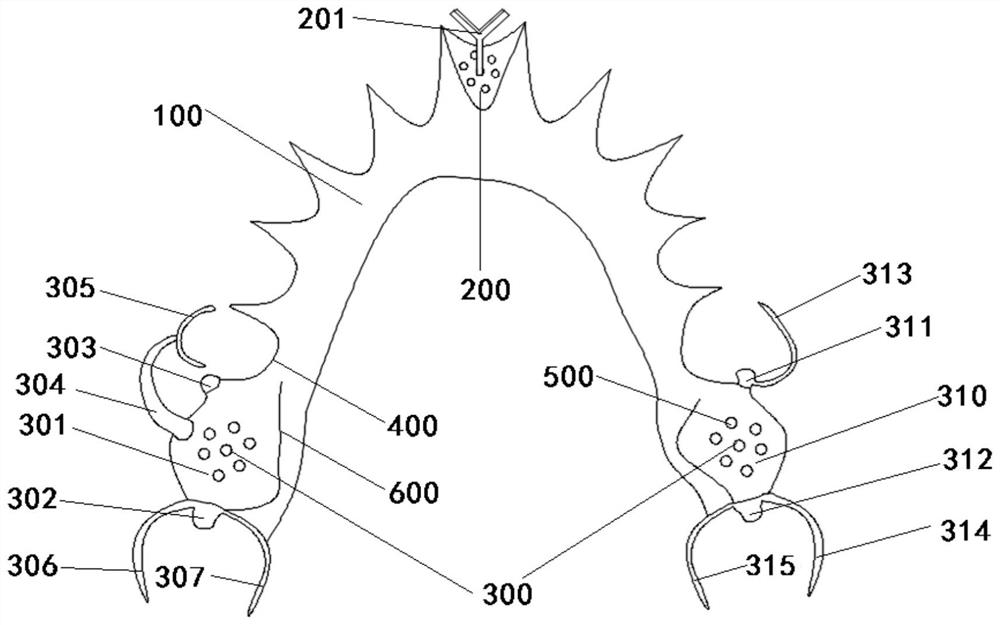

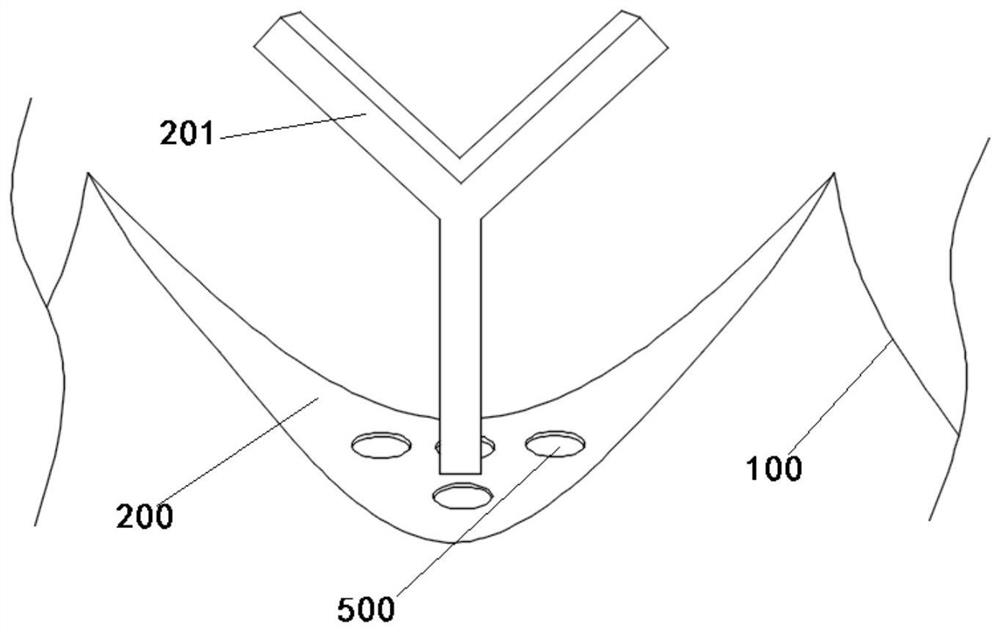

[0019] Such as figure 1 As shown, the titanium alloy denture bracket includes a jaw plate 100 that closely fits the patient's inner jaw. The jaw plate 100 is U-shaped, and the outer side of the jaw plate 100 has an arc-shaped edge 400 that is adapted to the contour of the neck of the remaining teeth and is used for The denture installation site covers the patient's missing gums. There is a certain gap between the denture installation site and the gums of the missing teeth to avoid scratching the gums and causing discomfort or injury. There are multiple through holes evenly distributed on the bottom surface of the denture installation site 500, forming a grid-like structure, and the installation positions of the dentures include the anterior tooth installation position 200 located at the center of the front side of the jaw plate 100 and the molar installation positions 300 located on both sides o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com