A kind of preparation method of urushiol oil-water separation membrane

An oil-water separation membrane, urushiol technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of high modification cost of metal materials, long preparation time for potential safety hazards, uncontrollable service life, etc. Large hydrophobic effect, low price, good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017]The preparation method of the paint phenolic water separation film provided by the present invention includes the following steps:

[0018]Painted phenol solution is formulated with ethanol as a solvent;

[0019]Soak the cotton fabric substrate in the prepared lacquerol solution;

[0020]The soaked cotton fabric substrate was taken out, and the drying treatment was carried out to give the painthenol water separation membrane.

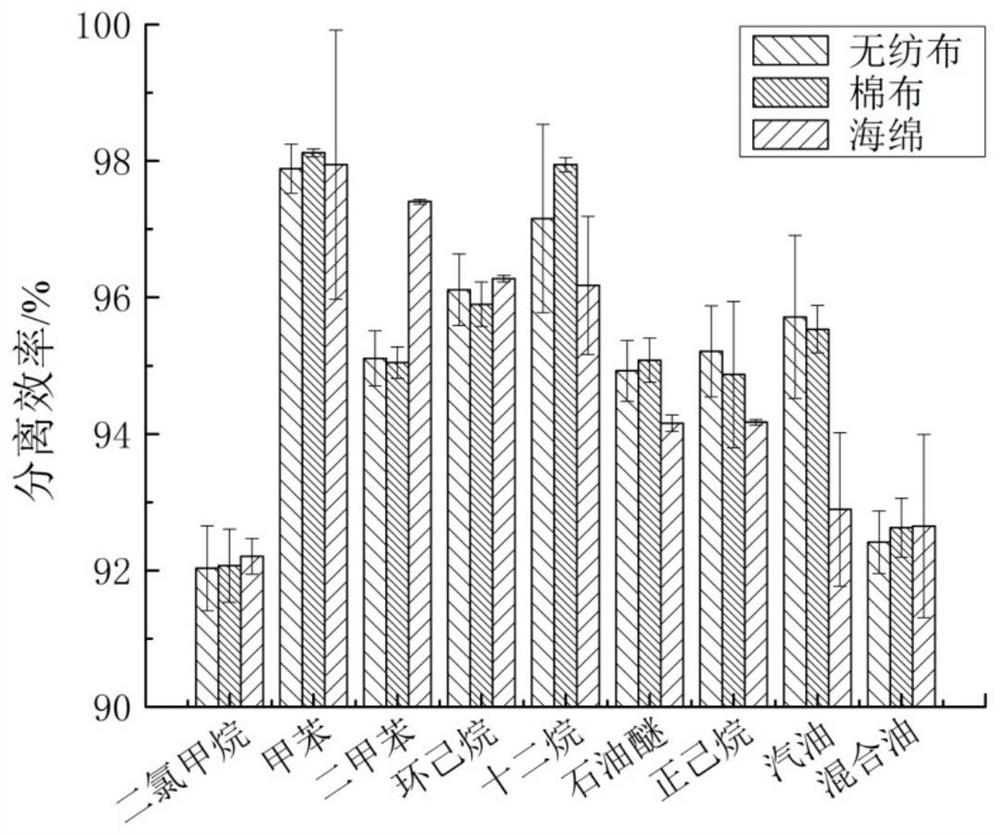

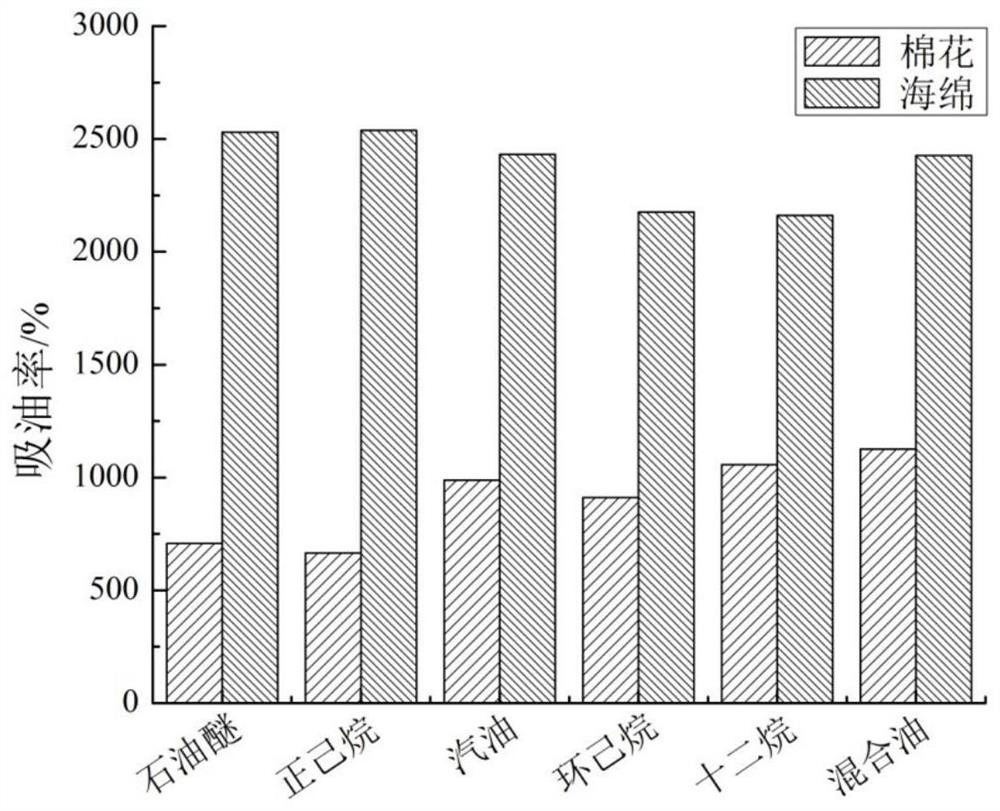

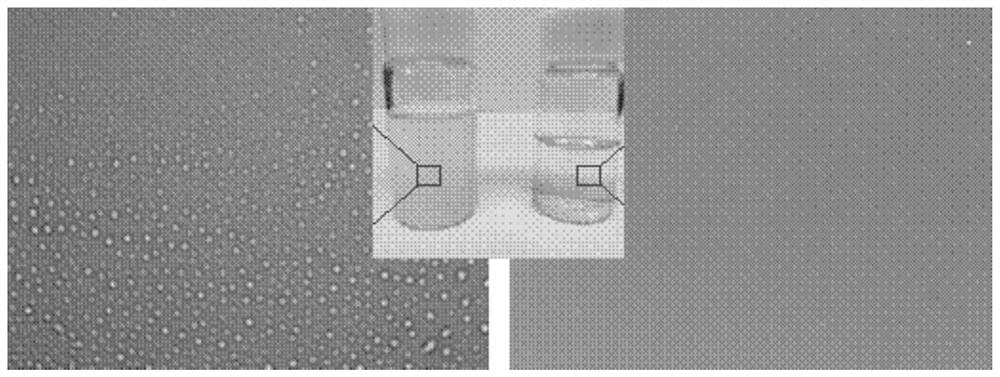

[0021]It can be seen from the above description, the advantageous effect of the present invention is that the cotton fabric substrate is modified by lacquerphenol, and the lacquer is coated on the surface of the cotton fabric substrate by solution impregnation method, and the surface energy of the cotton fabric substrate is reduced. The hydroxyl group on the cotton fabric substrate can be strongly complexed with lacquer, but also because the painthenol has a long side chain of hydrophobic properties, increases the hydrophobic effect of the cotton fabric substrate, ...

Embodiment 1

[0042]The solvent was prepared with ethanol as a solvent; the non-woven fabric was subjected to ultrasonic treatment in acetone for 15 min, dried into distilled water for 15 min, dried, and then placed in 0.01 mol / In the hydrochloric acid solution of L, then washed out of distilled water until neutral, then dried; a pre-treated nonwoven fabric was soaked in a phenolic solution of 60 mg / ml, and heating treatment and stirring treatment, said The heating temperature of the heat treatment was 50 ° C, the time was 24 h; the soaked nonwoven fabric was taken out, and the drying treatment was carried out at 120 ° C, and the time was 4 h, which obtained the paint-phenolic water separation film of the nonwoven fabric. .

Embodiment 2

[0044]Have a paint-phenol solution with ethanol as a solvent; the bio-oil and stains of the surface of the non-woven fabric were removed, and the obtained nonwoven fabric was soaked in a 40 mg / ml paint phenol solution, and the soaking nonwoven fabric was taken out. As in the oven, the drying treatment, the drying treatment, and the solidification treatment of the drying treatment is obtained by drying treatment, and the lacquer water separation film is obtained by the nonwoven fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com