Preparation method of low-loss nano crystal soft magnetic alloy

A nanocrystalline soft magnetic, low loss technology, applied in the direction of inductance/transformer/magnet manufacturing, magnetic objects, manufacturing tools, etc., can solve the problem that heat treatment conditions are not easy to control and operate, it is difficult to achieve comprehensive soft magnetic properties, high saturation magnetic Insensitivity and other issues to achieve the effect of broadening the product market and application prospects, increasing the nucleation rate and reducing the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In this example, Fe 76 Si 13 B 8 Nb 2 Cu 1 The preparation method of nanocrystalline soft magnetic alloy comprises the following steps:

[0049] (1) Dosing according to the alloy composition. After the master alloy is smelted, the quenched alloy strip is obtained by single-roll quenching technology, and the copper roll speed is 30m / s.

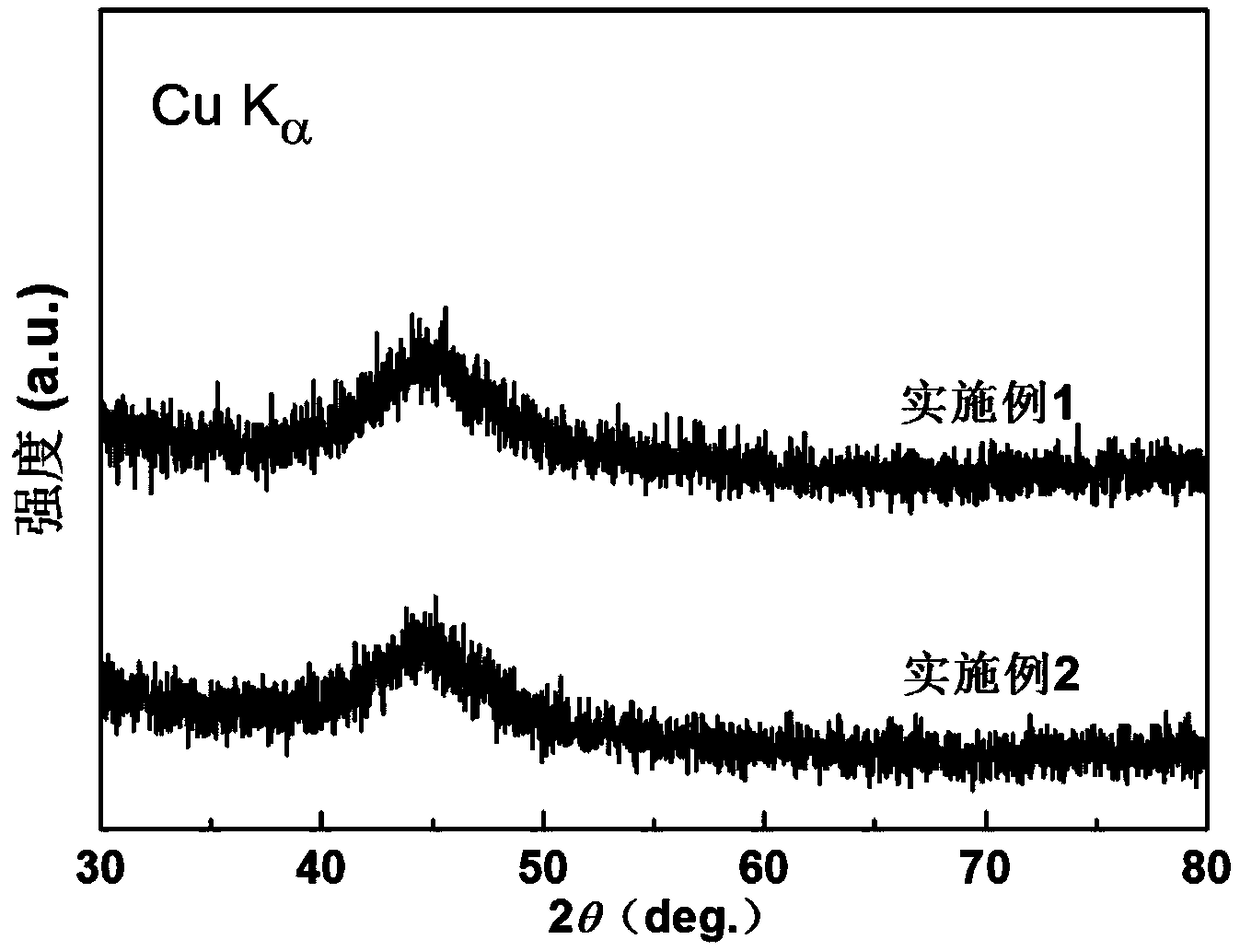

[0050] Adopt D8Advance type polycrystalline X-ray diffractometer (XRD) to detect the microstructure of this quenched strip material, the result is as follows figure 2 as shown, figure 2 It shows that the as-quenched strip has a broadened diffuse diffraction peak, indicating that the alloy as-quenched strip has an amorphous structure.

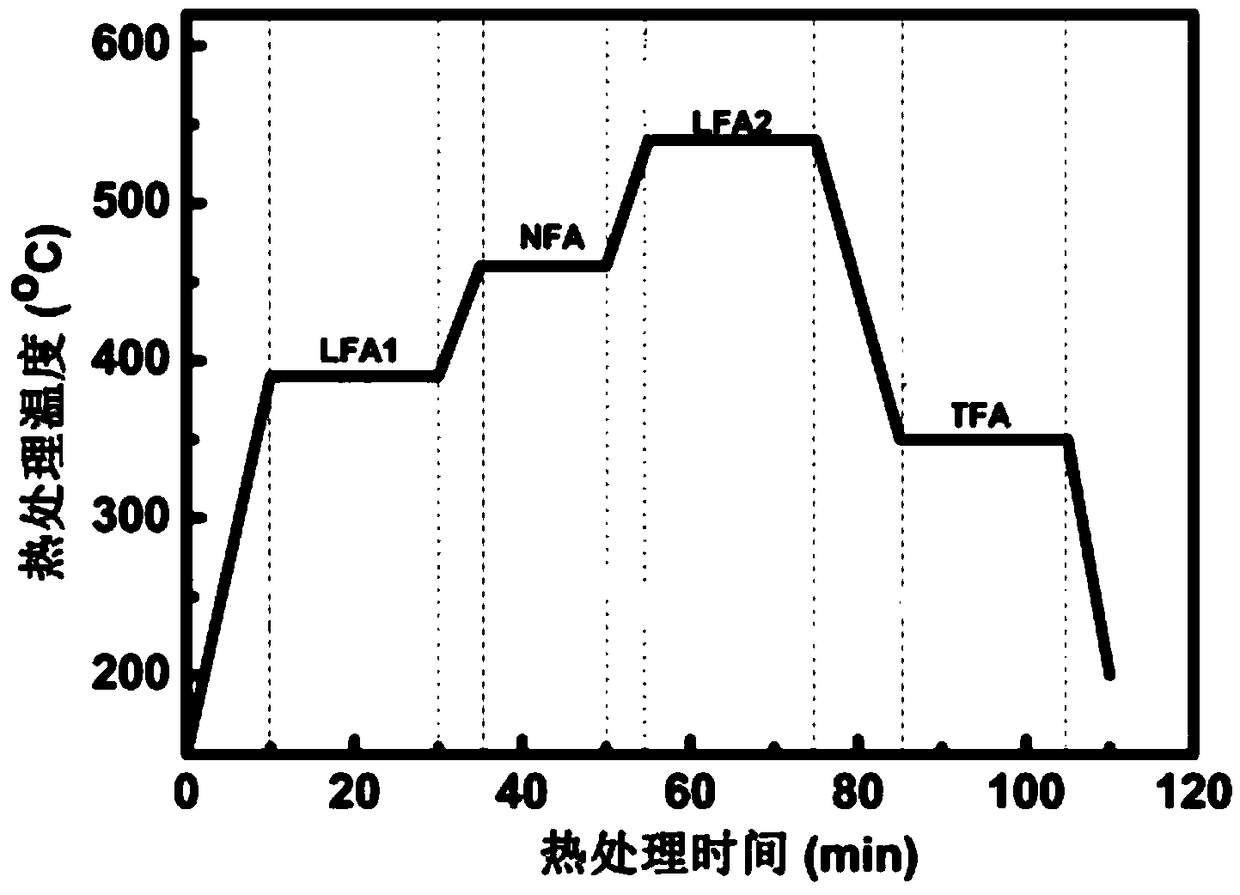

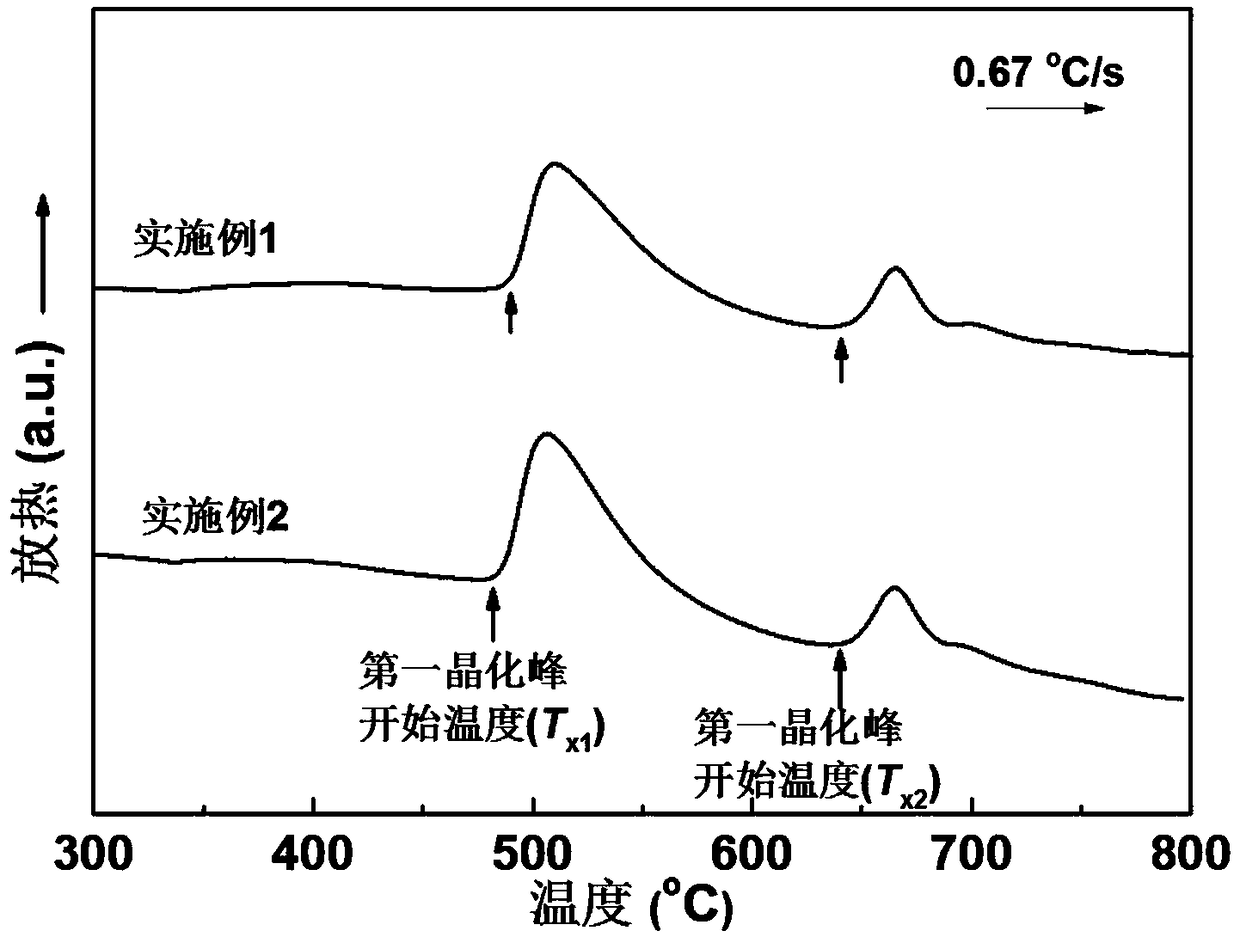

[0051] (2) Using NETZSCH DSC404C differential scanning calorimeter (DSC) to measure the crystallization temperature of the alloy strip at a heating rate of 0.67 °C / s, the results are as follows image 3 shown. As can be seen from the figure, the initial crystallization temperature of the first cr...

Embodiment 2

[0064] In this example, Fe 75.5 Si 13 B 8 Nb 2 Cu 1 (MoCTi) 0.5 The preparation method of nanocrystalline soft magnetic alloy comprises the following steps:

[0065] (1) Dosing according to the alloy composition. After the master alloy is smelted, the quenched alloy strip is obtained by single-roll quenching technology, and the copper roll speed is 30m / s.

[0066] Adopt D8Advance type polycrystalline X-ray diffractometer (XRD) to detect the microstructure of this quenched strip material, the result is as follows figure 2 as shown, figure 2 It shows that the as-quenched strip has a broadened diffuse diffraction peak, indicating that the alloy as-quenched strip has an amorphous structure.

[0067] (2) Using NETZSCH DSC404C differential scanning calorimeter (DSC) to measure the crystallization temperature of the alloy strip at a heating rate of 0.67 °C / s, the results are as follows image 3 shown. As can be seen from the figure, the initial crystallization temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com