Drilling fluid, preparation method and application

A drilling fluid and oil drilling technology, applied in chemical instruments and methods, drilling compositions, organic chemistry, etc., can solve the problems of easy instability of shale wellbore, maintain wellbore stability and prevent surface hydration , the effect of reducing the expansion pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

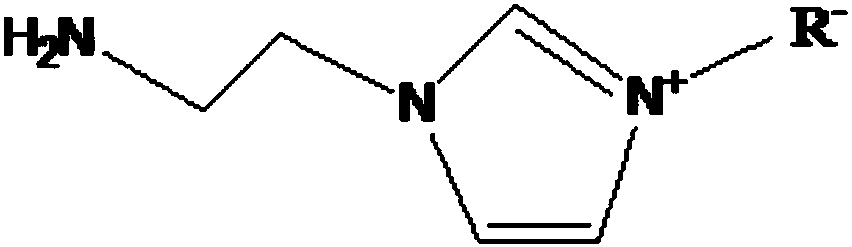

[0044] Preparation of 1-aminoethyl-3-methylimidazolium bromide:

[0045] The four-necked flask equipped with stirrer, nitrogen conduit, thermometer and condenser is placed in a constant temperature water bath, and 1-methylimidazole (8.20g, 0.10mol), 2-bromoethylamine hydrobromide ( 20.50 g, 0.10 mol) and 50 mL of acetonitrile, after stirring at 80 ° C for 4 h, the solution appeared to be separated, NaOH (4.0 g, 0.10 mol) was added to the mixture for neutralization, the NaBr precipitate was removed by filtration, and the upper layer solution containing the remaining reactant was poured out to remove , the lower layer solution was extracted with acetonitrile (5mL×3) to obtain 15.5g of a waxy product, which was the shale inhibitor 1-aminoethyl-3-methylimidazolium bromide salt of the present invention.

Embodiment 1

[0047] The 1-aminoethyl-3-methylimidazolium bromide salt prepared in the preparation example was dissolved in tap water to prepare an aqueous solution with a concentration of 1% by weight. Five parts of 300 mL of 1% by weight 1-aminoethyl-3-methylimidazolium bromide aqueous solution were respectively selected for the determination of inhibitory effect evaluation.

Embodiment 2

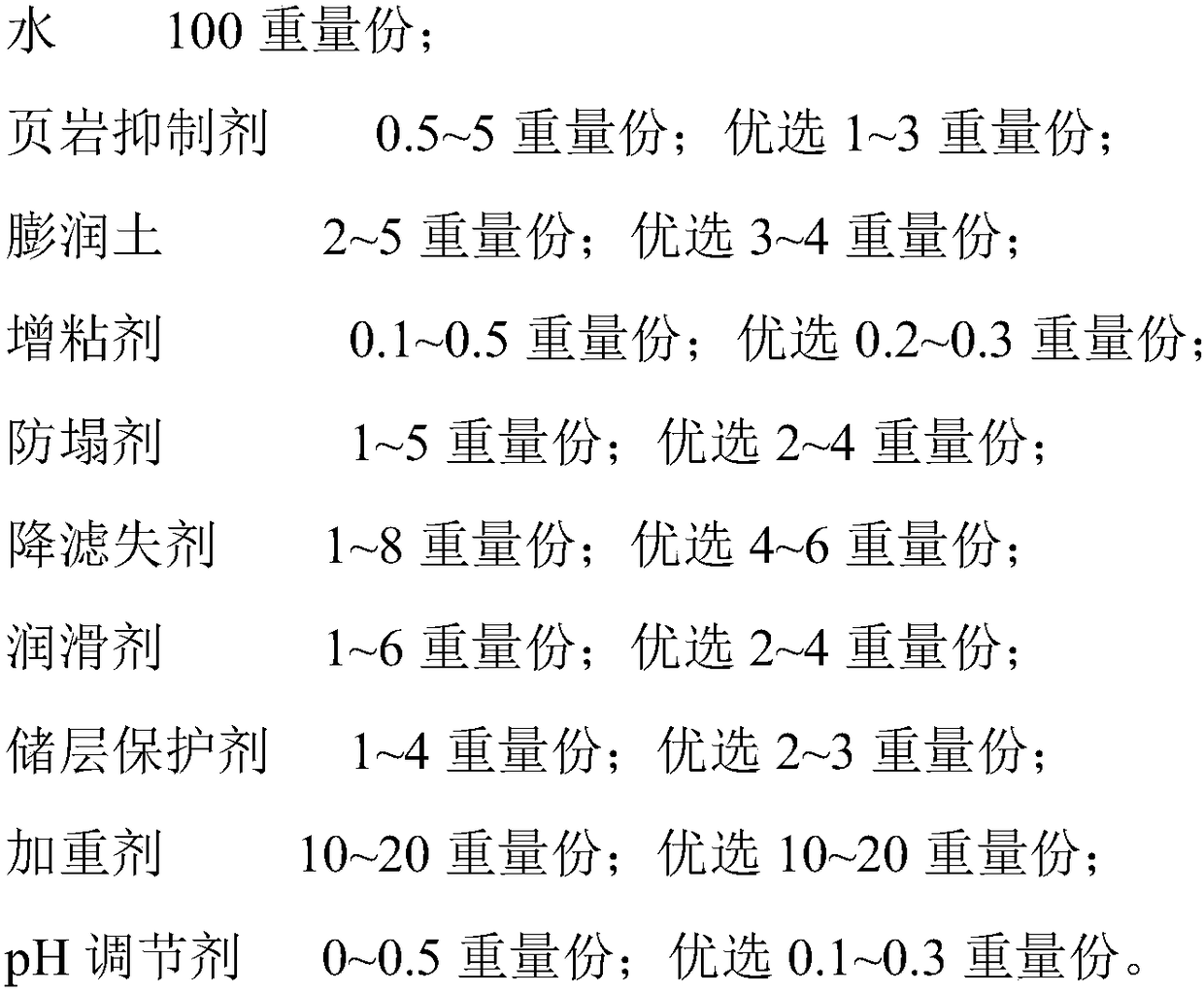

[0061] Configure water-based drilling fluid according to the following formula: 100 parts by weight of water, 3 parts by weight of sodium bentonite, 0.2 parts by weight of potassium hydroxide, 0.3 parts by weight of Welan gum, 3 parts by weight of sulfonated bitumen, 4 parts by weight The sulfonated phenolic resin, the sulfonated lignite resin of 2 parts by weight, the pentaerythritol oleate of 2 parts by weight, the calcium carbonate of 3 parts by weight, the barite (barium sulfate content is 93% by weight) of 10 parts by weight, and respectively Add 1 part by weight of the shale inhibitor of the preparation example to obtain drilling fluid A1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com