Single-component boiled adhesive easy to boil and degum and preparation method thereof

A one-component, degumming technology, used in chemical instruments and methods, adhesives, adhesive types, etc., can solve the problems of long boiling degumming time and low bonding strength, to ensure stability and efficient bonding ability. , The effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation components of the one-component boiled glue include: 46 parts by mass of hydroxypropyl methacrylate, 25 parts by mass of urethane acrylate, 4 parts by mass of hydrophilic monomer, 4 parts by mass of hydrophilic resin, 1 part by mass of accelerator, 1 part by mass of peroxide initiator, 1 part by mass of anti-settling agent, and 6 parts by mass of foaming agent. The hydrophilic monomer is polyethylene glycol methacrylate, and the hydrophilic resin is a polyacrylic resin.

[0028] The preparation method of one-component boiled glue that is easy to boil and degummed includes the following steps:

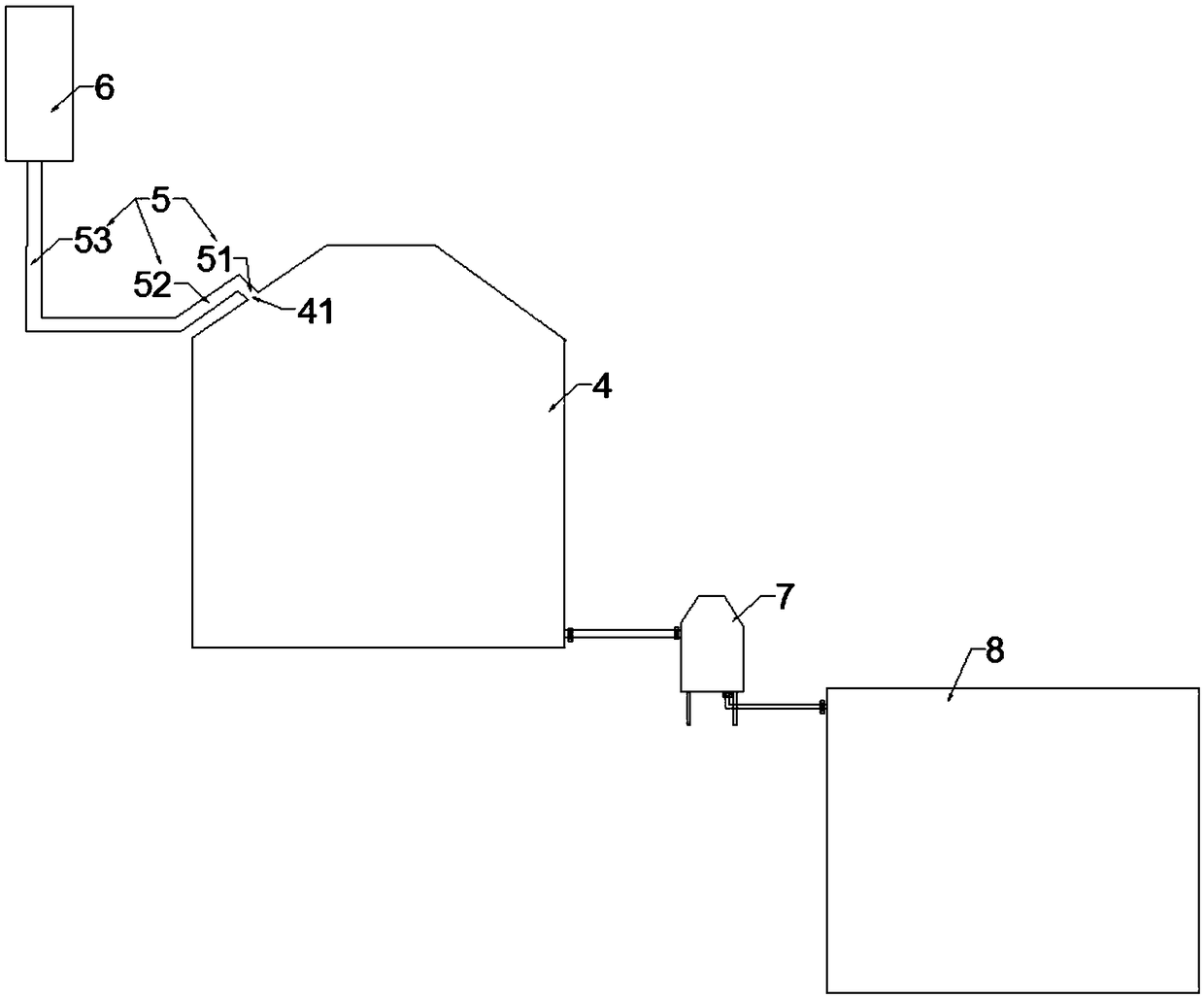

[0029] Step 1. Weigh hydroxyethyl methacrylate and urethane acrylate in parts by mass and add them to the reactor 4, stir evenly to obtain a mixed solution;

[0030] Step 2: Add the hydrophilic monomer and the hydrophilic resin to the mixed solution in order by mass parts and stir until uniform, the accelerator is stirred until uniform, the initiator is stirred until un...

Embodiment 2

[0032] The preparation components of the one-component boiled glue include: 50 parts by mass of hydroxypropyl methacrylate, 30 parts by mass of urethane acrylate, 6 parts by mass of hydrophilic monomer, 8 parts by mass of hydrophilic resin, 2 parts by mass of accelerator, 2 parts by mass of peroxide initiator, 1 part by mass of anti-settling agent, and 10 parts by mass of foaming agent.

[0033] The hydrophilic monomer is polyethylene glycol methacrylate, and the hydrophilic resin is a polyacrylic resin.

[0034] The preparation method of one-component boiled glue that is easy to boil and degummed includes the following steps:

[0035] Step 1. Weigh hydroxyethyl methacrylate and urethane acrylate in parts by mass and add them to the reactor 4, stir evenly to obtain a mixed solution;

[0036] Step 2: Add the hydrophilic monomer and the hydrophilic resin to the mixed solution in order by mass parts and stir until uniform, the accelerator is stirred until uniform, the initiator is stirre...

Embodiment 3

[0038] The preparation components of the one-component boiled glue include: 48 parts by mass of hydroxypropyl methacrylate, 28 parts by mass of urethane acrylate, 5 parts by mass of hydrophilic monomer, 6 parts by mass of hydrophilic resin, 1.5 parts by mass of accelerator, 1.5 parts by mass of peroxide initiator, 1 part by mass of anti-settling agent, and 8 parts by mass of foaming agent.

[0039] The hydrophilic monomer is polyethylene glycol methacrylate, and the hydrophilic resin is a polyacrylic resin.

[0040] The preparation method of one-component boiled glue that is easy to boil and degummed includes the following steps:

[0041] Step 1. Weigh hydroxyethyl methacrylate and urethane acrylate in parts by mass and add them to the reactor 4, stir evenly to obtain a mixed solution;

[0042] Step 2: Add the hydrophilic monomer and the hydrophilic resin to the mixed solution in order by mass parts and stir until uniform, the accelerator is stirred until uniform, the initiator is sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com