A method for decolorizing and degrading dye wastewater by using alkali/solid oxidant system

A technology for dye wastewater and oxidant, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc. problem, to achieve the effect of fast response rate, green and safe operation cost, and low operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

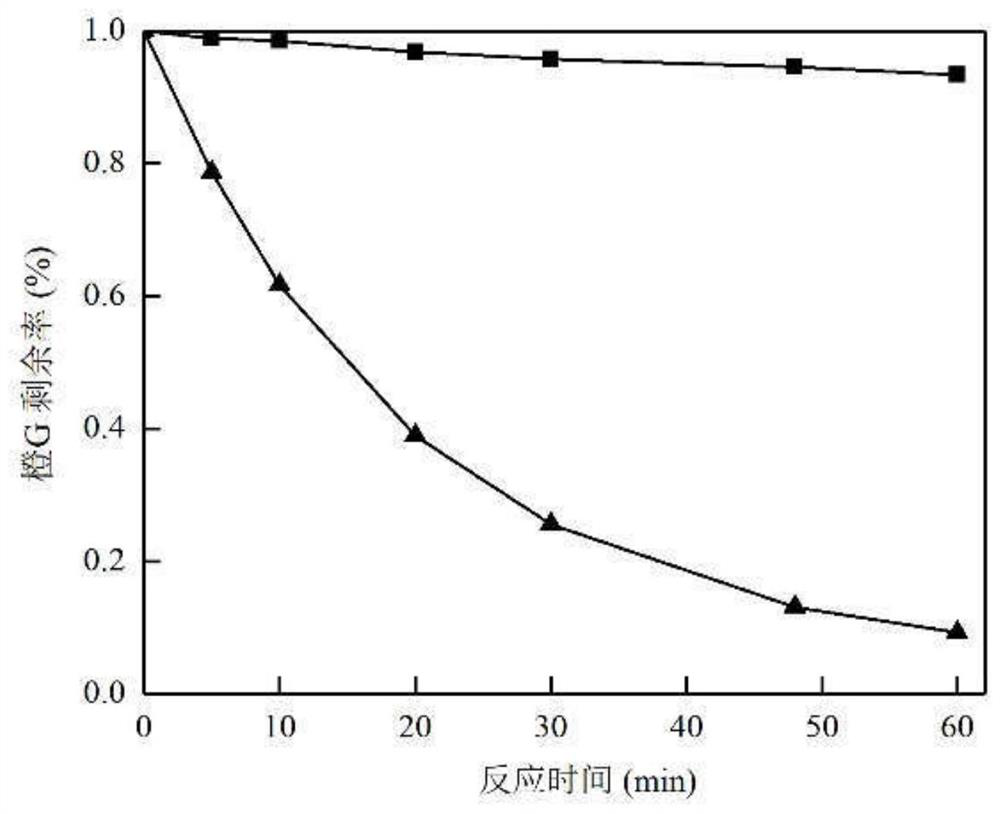

[0024] Use alkali to adjust the pH value of the dye orange G wastewater to be treated to 11, then add sodium percarbonate to the water body, stir and react evenly at a temperature of 25°C for 60 minutes, and then complete the method of decolorizing and degrading dye wastewater by using an alkali / solid oxidant system ; Wherein, the molar ratio of organic pollution and solid oxidant in the dye wastewater to be treated is 0.1:12.

[0025] The curve graph of the removal effect of orange G and the removal effect of orange G when no alkali is added in the present embodiment is as follows figure 1 Shown; Among them, ▲ is the removal effect curve of orange G in test 1; ■ is the removal effect curve of orange G when no alkali is added. from figure 1 It can be seen from the figure that after adding alkali to the solid oxidant, the generation of free radicals in the reaction and the removal of pollutants are obviously promoted. As time goes by, the remaining orange G is less and less. A...

Embodiment 2

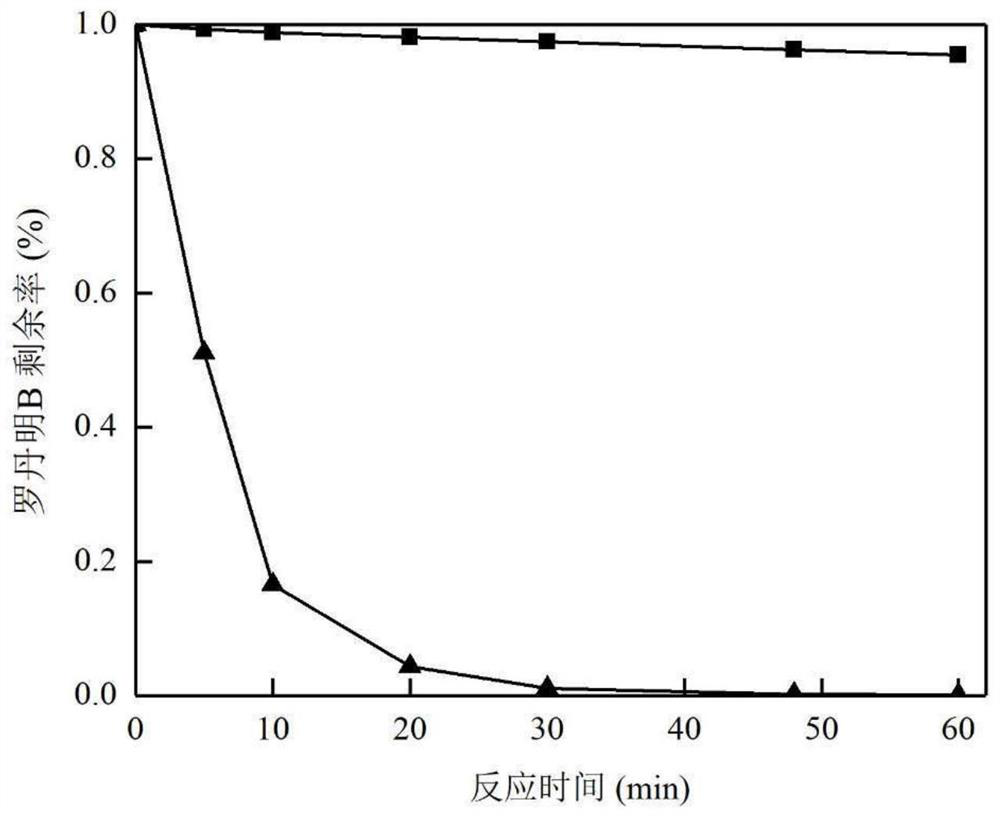

[0027] Use alkali to adjust the pH value of the dye Rhodamine B wastewater to be treated to 13, then add calcium percarbonate to the water body, uniformly stir and react for 60 minutes at a temperature of 25°C, and then complete the decolorization and degradation of the dye wastewater by using the alkali / solid oxidant system Method; wherein, the molar ratio of organic pollutants and solid oxidants in the dye wastewater to be treated is 0.1:12.

[0028] The curve graph of the removal effect of rhodamine B in this embodiment acid and the removal effect of rhodamine B when no alkali is added is as follows figure 2 Shown; Wherein, ▲ is the removal effect curve of test two Rhodamine B; ■ is the curve of the removal effect of Rhodamine B when no alkali is added. from figure 2 It can be seen that after adding alkali to the solid oxidant, the generation of free radicals in the reaction and the removal of pollutants are obviously promoted. With the increase of time, the remaining rh...

Embodiment 3

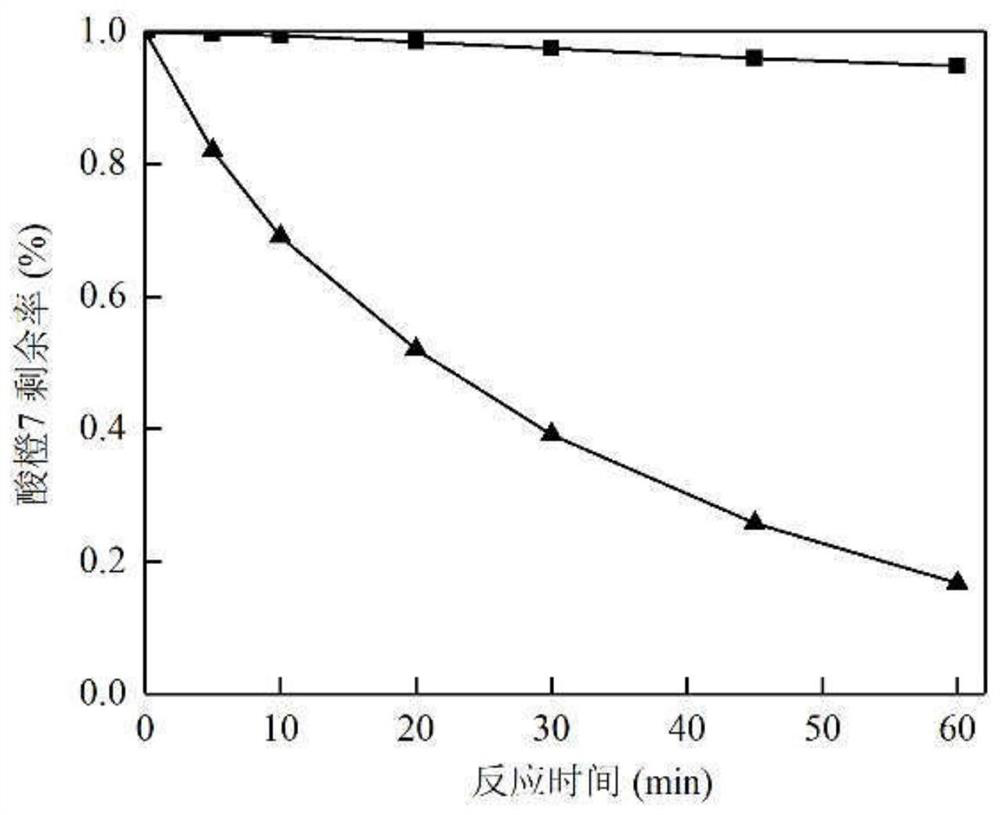

[0030] Use alkali to adjust the pH value of the dye lime 7 wastewater to be treated to 11, then add sodium perborate to the water body, stir and react evenly at a temperature of 25°C for 60 minutes, and then complete the decolorization and degradation of the dye wastewater by using the alkali / solid oxidant system Method; wherein, the molar ratio of organic pollutants and solid oxidants in the dye wastewater to be treated is 0.1:12.

[0031] The curve graph of the removal effect of lime 7 and the removal effect of lime 7 when no alkali is added in the present embodiment is as follows image 3 Shown; Wherein, ▲ is the removal effect curve of test two lime 7; ■ is the curve of the removal effect of lime 7 when no alkali is added. from image 3 It can be seen from the figure that after adding alkali to the solid oxidant, the generation of free radicals in the reaction and the removal of pollutants were obviously promoted. With the increase of time, the remaining lime 7 became les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com