Method for purifying crude selenium through anhydrous ethanol

A technology of absolute ethanol and crude selenium, which is applied in the field of hydrometallurgical engineering, can solve the problems of long production cycle, high requirements for test conditions, and long time consumption, and achieve the effect of efficient extraction and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

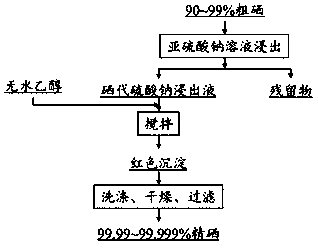

Method used

Image

Examples

Embodiment 1

[0019] A method for purifying crude selenium with dehydrated alcohol, specifically comprises the following steps:

[0020] The crude selenium raw material is crushed, passed through a 50-mesh sieve, and then 300ml of 300g / L sodium sulfite solution is prepared and the crude selenium raw material with a purity of 90% is added to the reaction kettle at the same time according to the liquid-solid ratio of 15:1, and the temperature is controlled at 120°C. The stirring speed is 350r / min, the reaction is carried out under heating in an oil bath and magnetic stirring for 3 hours, and the selenium-containing leachate is obtained by filtration.

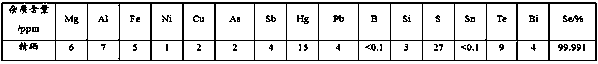

[0021] Use a measuring cylinder to measure excess absolute ethanol and add it to the sodium selenosulfate leaching solution, and immediately obtain selenium precipitate under the condition of stirring speed of 320r / min, and then filter, wash, and dry (60°C) to obtain refined selenium ; With reference to the People's Republic of China Nonferrous...

Embodiment 2

[0025] A method for purifying crude selenium with dehydrated alcohol, specifically comprises the following steps:

[0026] Crush the crude selenium raw material, pass through a 50-mesh sieve, prepare 300ml of 300g / L sodium sulfite solution and add the crude selenium raw material with a purity of 93% into the reaction furnace at the same time according to the liquid-solid ratio of 20:1. 300r / min, react for 2h under mechanical stirring, and filter to obtain sodium selenosulfate leaching solution.

[0027] Use a measuring cylinder to measure excess absolute ethanol and add it to the sodium selenosulfate leaching solution to obtain selenium precipitates, which are then filtered, washed, and dried (60°C) to obtain refined selenium; the obtained refined selenium refers to the nonferrous metal industry of the People's Republic of China According to the standards YS / T223-2007 and YS / T226.13-2009, the purity of refined selenium is detected by inductively coupled plasma mass spectrometr...

Embodiment 3

[0031] A method for purifying crude selenium with dehydrated alcohol, specifically comprises the following steps:

[0032] The coarse selenium raw material is pulverized, crosses 50 mesh sieves, the thick selenium raw material is processed, the sodium sulfite solution 300ml of preparation 300g / L and purity are 99% thick selenium raw material is that 9:1 is added in the reaction furnace simultaneously by liquid-solid ratio, control The temperature was 50° C., the stirring speed was 200 r / min, the reaction was performed under mechanical stirring for 1.5 h, and the sodium selenosulfate leaching solution was obtained by filtration.

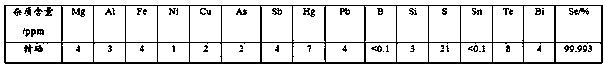

[0033] Use a measuring cylinder to measure excess absolute ethanol and add it to the sodium selenosulfate leaching solution to obtain selenium precipitates, which are then filtered, washed, and dried (60°C) to obtain refined selenium; the obtained refined selenium refers to the nonferrous metal industry of the People's Republic of China According to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com