Application of water-soluble fullerene structure in preparation of medicine for treating pulmonary fibrosis

A water-soluble, fullerene technology, applied in the field of medicine, can solve problems such as poor long-term efficacy, weak efficacy in chronic pulmonary fibrosis, and short duration of anti-inflammatory effect of glucocorticoids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1. Hydroxyl-modified metal fullerene Gd@C 82 And hydroxyl modified hollow fullerene C 70 Preparation

[0057] (a) Add 7mL of 30% by mass hydrogen peroxide aqueous solution and 3mL of 40% by mass sodium hydroxide solution into a 100mL round bottom flask, and then add 200mg Gd@C 82 Or C 70 Then, add a magnetic stirrer (model: B200) and use a magnetic stirrer to stir for 24 hours at a temperature of 70° C. and a rotation speed of 1000 r / min. Use a solvent filter with a membrane pore size of 200 nm to filter to obtain a brown-yellow solution.

[0058] (b) Put the brown-yellow solution obtained in step (a) into a 50ml centrifuge tube, then add an excess of 95% ethanol, centrifuge at 10000r / min for 4min, remove the upper colorless solution, and collect The precipitate was dissolved in ultrapure water to obtain a yellow clear solution.

[0059] (c) Put the yellow clear solution obtained in step (b) into a dialysis bag with a molecular weight cut-off of 3500 and place it in ul...

Embodiment 2

[0061] Example 2: Water-soluble GF-OH and C 70 -Determination of the content of each element in OH

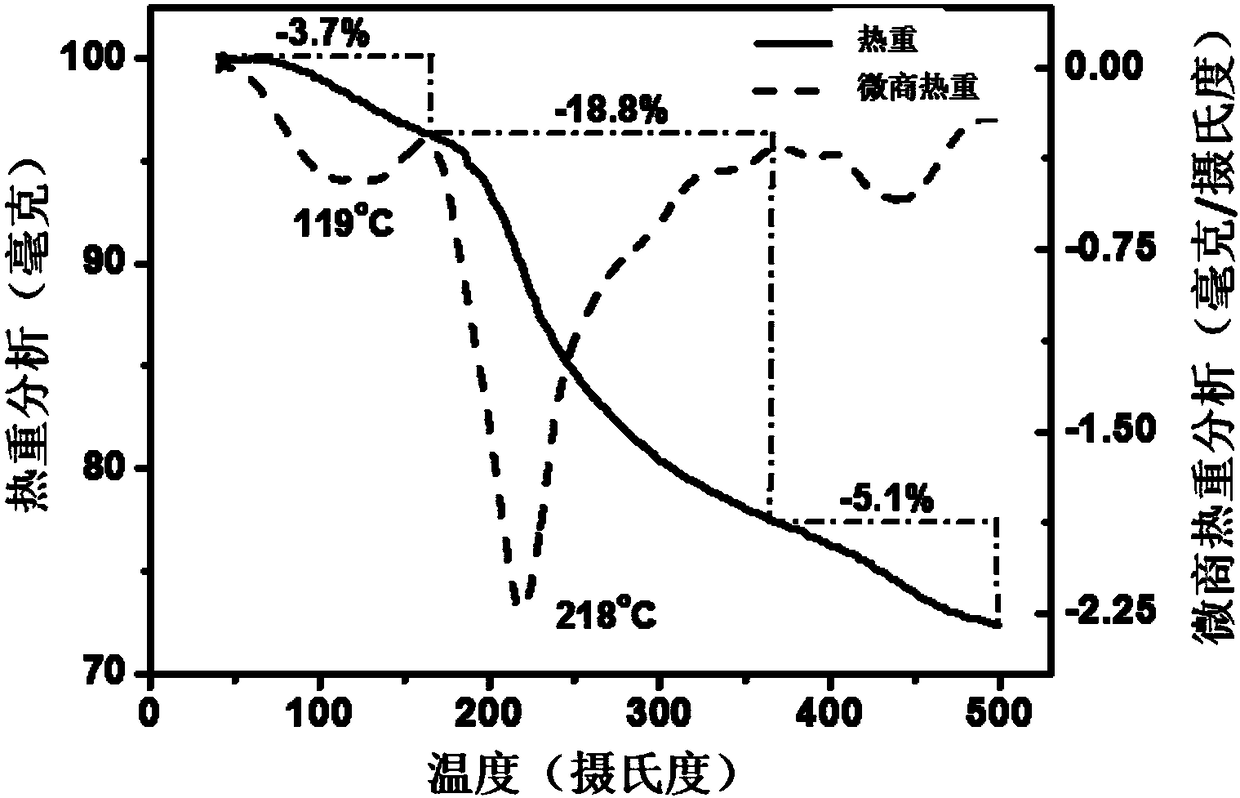

[0062] For the C prepared in Example 1 above 70 -OH nanoparticles are subjected to elemental analysis (Flash EA1112), and combined with thermogravimetric and derivative thermogravimetric results to analyze the number of hydroxyl groups attached. In the results of elemental analysis, the C 70 -OH, C content is 37.85%, H content is 1.51%, N content figure 1 ) It can be seen that C 70 -OH solid powder contains 3.7% water, which is about 5 water molecules. Combined with the ratio of H content to C content in elemental analysis, it can be inferred that the surface of the carbon cage is modified with 24 hydroxyl groups. So C 70 The average structural formula of -OH is C 70 (OH) 24 ·5H 2 O.

[0063] For the Gd@C prepared in Example 1 above 82 The corresponding hydroxylated derivative (hereinafter referred to as Gd@C 82 (OH) n ) Perform elemental analysis, the C content is 76.6%, the H cont...

Embodiment 3

[0064] Example 3: Water-soluble GF-OH and C 70 -OH hydrated particle size determination

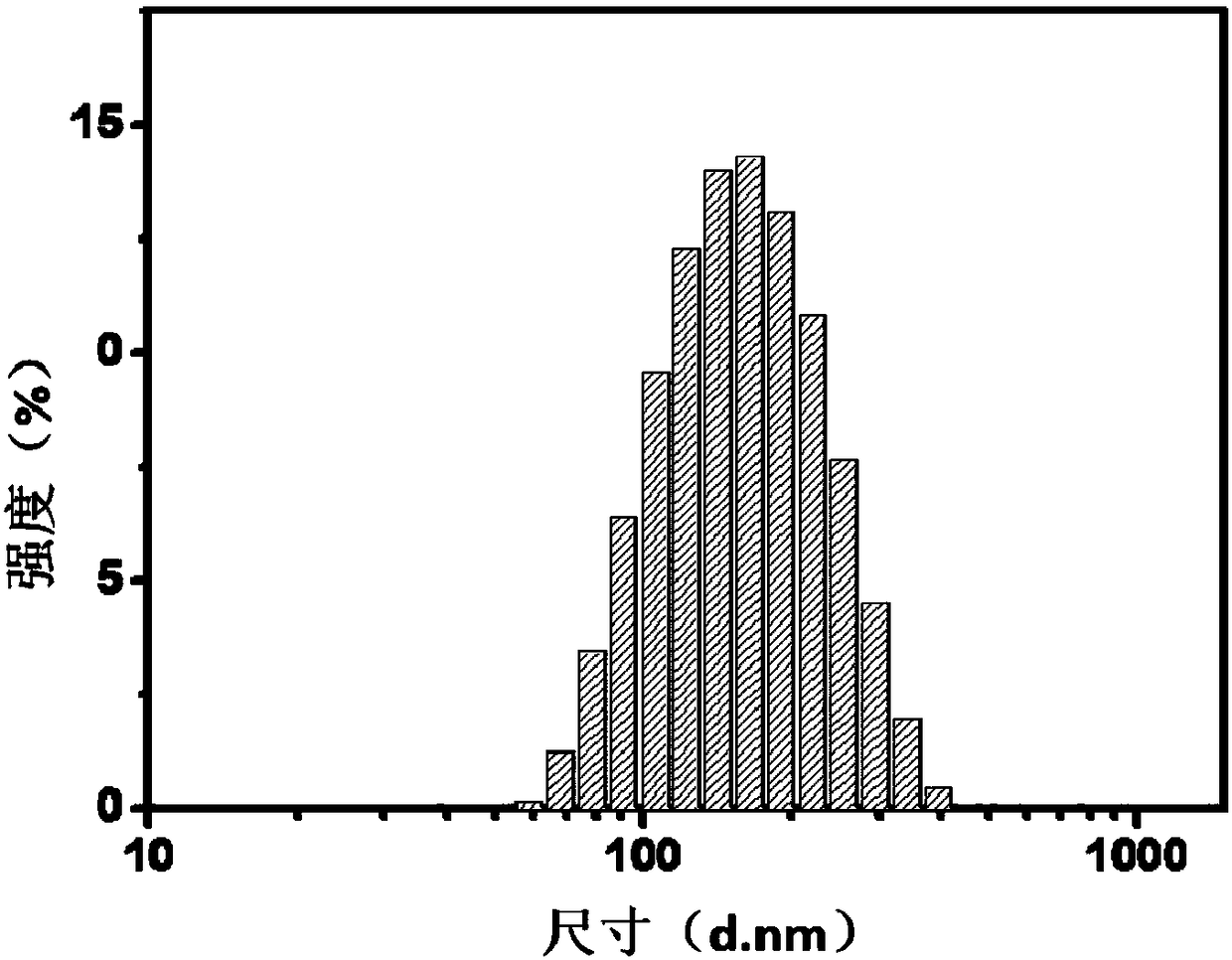

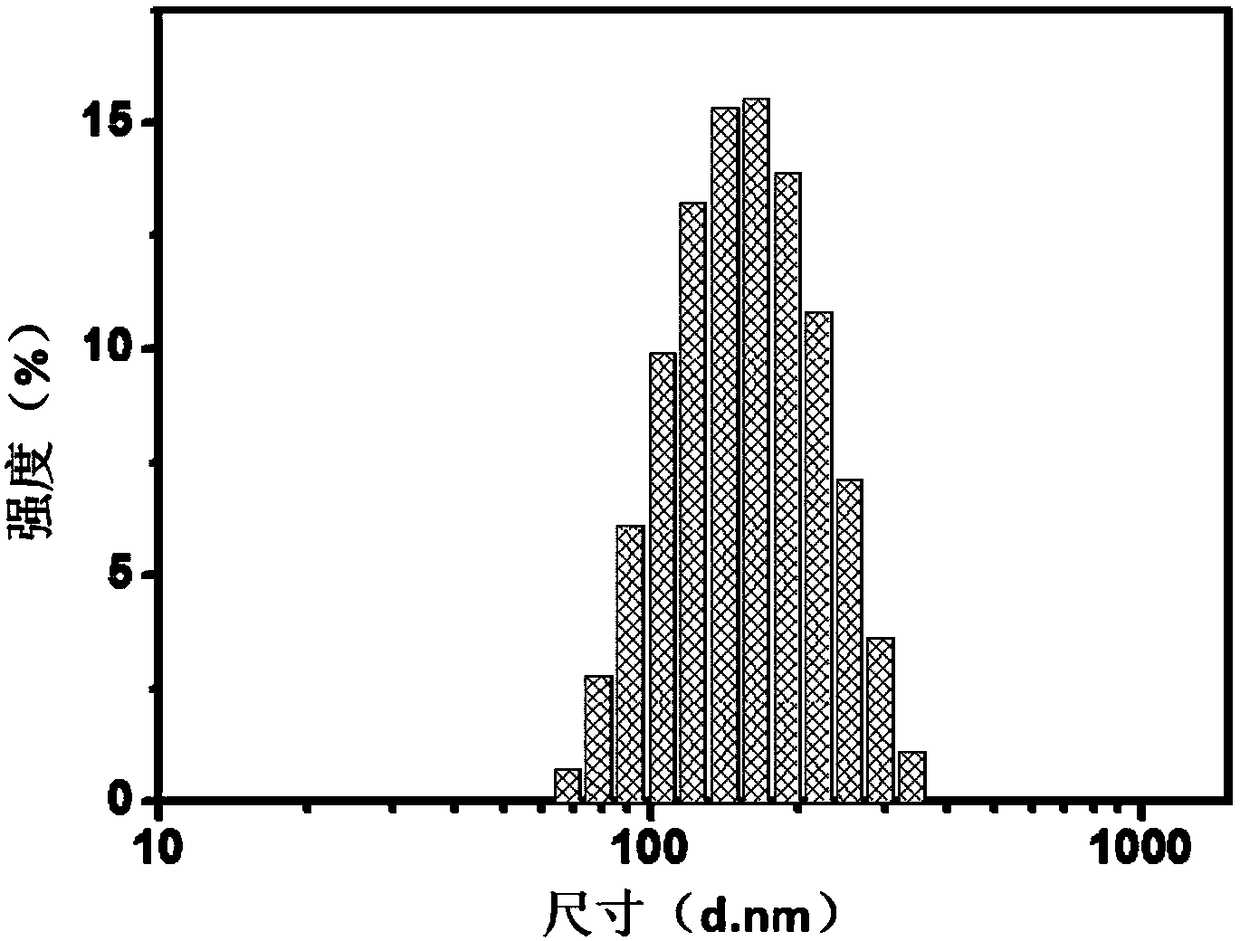

[0065] Take a small amount of GF-OH and C prepared in Example 1 of the present invention 70 -OH powder was dissolved in pure water with pH=7.0 to form a dilute solution of 100μM / L. Due to the intermolecular interaction, GF-OH and C 70 -OH agglomerates into nanoparticles in water, forming particles with an average hydrated particle size of 1-200nm.

[0066] Dynamic light scattering (DLS, Zetasizer Nano ZSP) was used to determine the hydrated particle size of nanoparticles in pure water at pH=7.0. The average particle size of GF-OH is 146.1nm. For the particle size distribution curve, see figure 2 ; C 70 The average particle size of -OH is 135.9nm, see the particle size distribution curve image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com