A preparation method of perovskite thin film and a preparation method of solar cell thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complex evaporation control, and achieve the effect of solving complex control, easy control, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

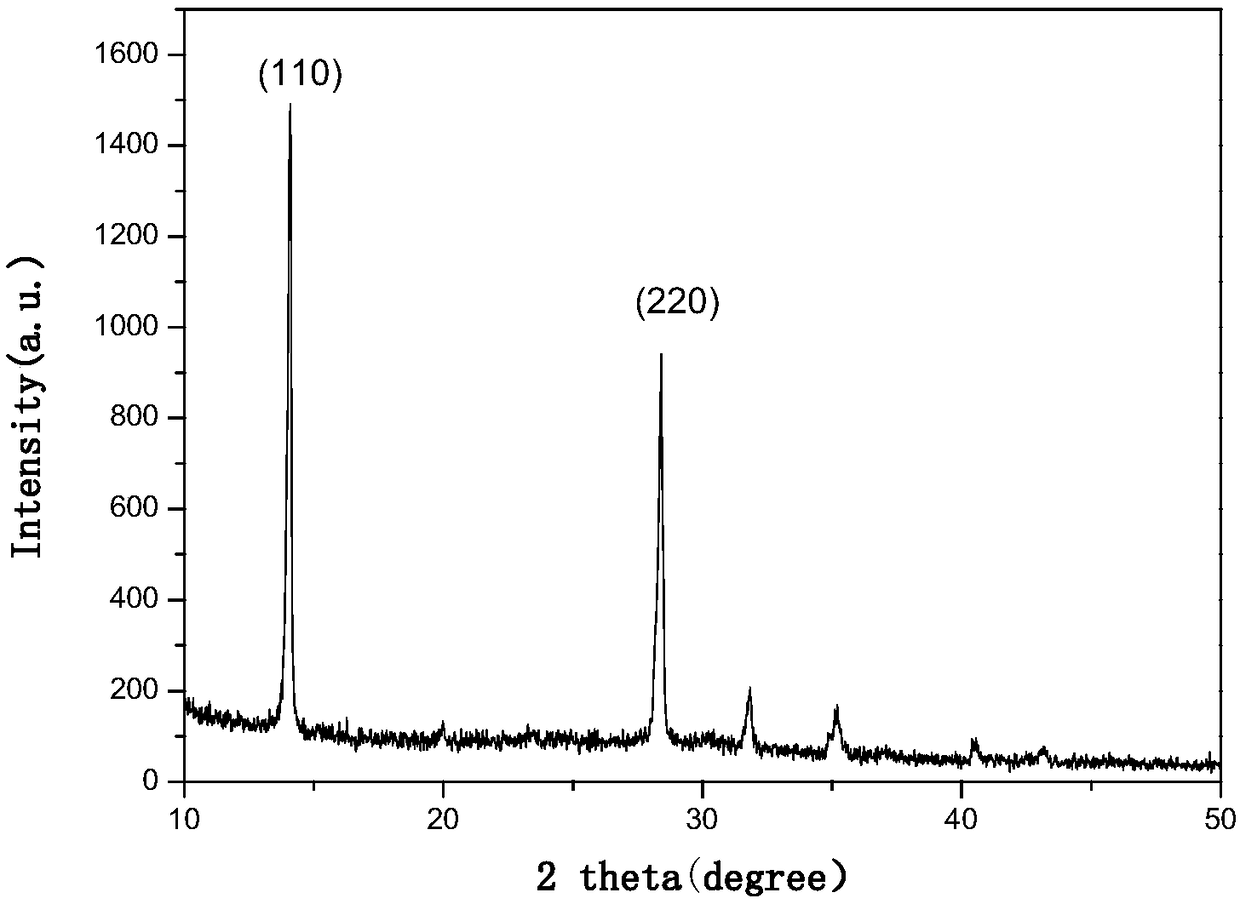

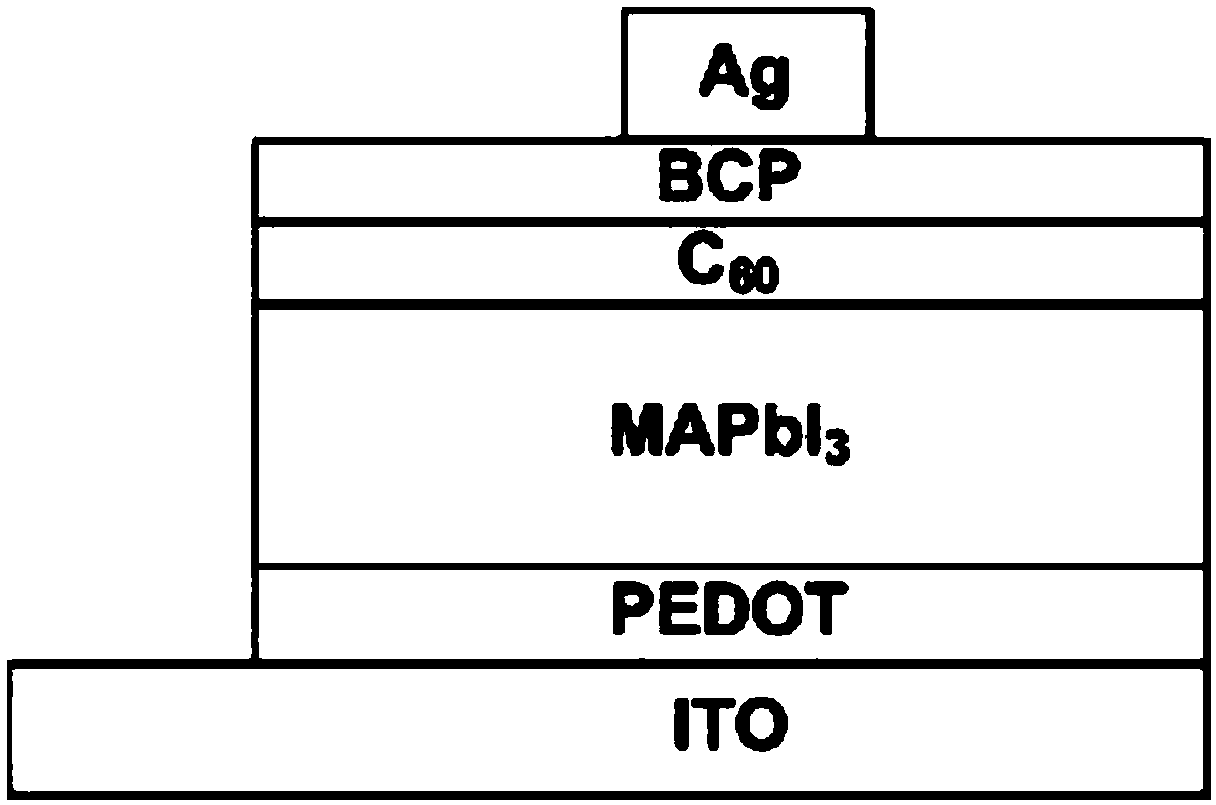

[0029] The invention provides a method for preparing a perovskite thin film, wherein the perovskite ABX 3 The raw materials are composed of metal halides, and organic or inorganic salts; the metal halides are BX 2 , B is the cationic Pb 2+ , Sn 2+ or Ge 2+; The organic salt or inorganic salt is AX, and A is methylamine cation, formamidine cation or cesium Cs + ; X is anion Cl - , Br - or I - one or a combination of more. Specifically, the following steps are included:

[0030] In step S1, firstly, the evaporation boat is pretreated, including cleaning and drying the evaporation boat; then, the evaporation boat is subjected to ultraviolet-ozone or plasma treatment for at least 2 minutes.

[0031] Optionally, the evaporation boat is cleaned with deionized water, acetone, ethanol, and deionized water in sequence, and the cleaning time is 15 minutes each time; then, the evaporation boat is dried with nitrogen or infrared.

[0032] Optionally, evenly spread the AX salt sol...

Embodiment 1

[0059] Perovskite raw material ABX in the present embodiment 3 In AX select MAI; BX 2 for PbI 2 ; The evaporation boat is made of molybdenum sheet.

[0060] The specific process is as follows: first, use deionized water, acetone, ethanol and deionized water to clean the evaporation boat in sequence, and the cleaning time is 15 minutes each time, then use nitrogen to dry the evaporation boat, and then use ultraviolet-ozone to treat the evaporation boat. 5min; then spread the prepared MAI solution evenly on the surface of the evaporating boat, the concentration of MAI is 3M, and the solvent is DMF; then dry the evaporating boat, the drying process is, drying at 80°C for 5min, Then, it was dried at 120° C. for 5 minutes, and a layer of MAI solid was uniformly and densely distributed on the surface of the obtained evaporation boat.

[0061] Then fix the evaporation boat in the chamber of the evaporation machine, put the substrate, and the distance between the substrate and the ...

Embodiment 2

[0064] Perovskite raw material ABX in the present embodiment 3 In AX select CsCl,; BX 2 for GeCl 2 ; The evaporation boat is made of tungsten sheet.

[0065] The specific process is as follows: first, use deionized water, acetone, ethanol and deionized water to clean the evaporation boat in sequence, each cleaning time is 16 minutes, then use infrared to dry the evaporation boat, and use ultraviolet-ozone to dry the evaporation boat Treat for 4 minutes; then apply the prepared CsCl solution evenly on the surface of the evaporating boat, where the concentration of CsCl is 0.1M, and the solvent is butanol; then dry the evaporating boat at 80°C After drying for 5 minutes, and then drying at 120° C. for 5 minutes, a layer of CsCl solid is uniformly and densely distributed on the surface of the obtained evaporation boat; 0.1 wt % cetyltrimethylammonium bromide is added to the CsCl solution.

[0066] Then fix the evaporation boat in the chamber of the evaporation machine, set the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com