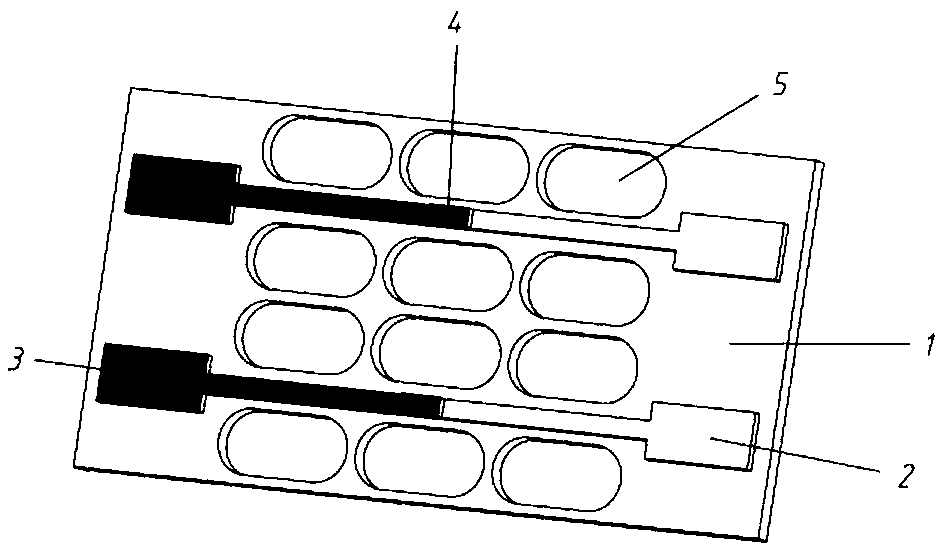

A method for manufacturing a thin film thermocouple for measuring a local temperature of a fuel cell

A local temperature and fuel cell technology, applied in fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problems of low metal mask processing accuracy and limited spatial resolution of temperature measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] 1 cleaning silicon wafer

[0137] Clean the silicon wafer with piranha washing solution (H2SO4:H2O2=3:1) to remove organic impurities on the surface of the silicon wafer. Remove the wafer from the piranha solution and rinse the wafer with deionized water. Use a CDA air gun to dry the water on the surface of the silicon wafer.

[0138] 2 Plating sacrificial layer

[0139] Put the silicon wafer on the electric heating plate and heat it for 5 minutes, and set the temperature of the electric heating plate to 100 degrees Celsius to dry the moisture on the surface of the silicon wafer. Leave the silicon wafer at room temperature and wait for the temperature of the silicon wafer to drop to room temperature. Use an evaporation machine or a magnetron sputtering system to coat a layer of aluminum on the silicon wafer, and the thickness of the aluminum is about 80 nanometers. Aluminum serves as a sacrificial layer for finally peeling off the thin-film thermocouple 6 .

[0140...

Embodiment 2

[0153] 1 cleaning silicon wafer

[0154] Clean the silicon wafer with piranha washing solution (H2SO4:H2O2=3:1) to remove organic impurities on the surface of the silicon wafer. Remove the wafer from the piranha solution and rinse the wafer with deionized water. Use a CDA air gun to dry the water on the surface of the silicon wafer.

[0155] 2 Plating sacrificial layer

[0156] Put the silicon wafer on the electric heating plate and heat it for 15 minutes. The temperature of the electric heating plate is set at 120 degrees Celsius to dry the moisture on the surface of the silicon wafer. Leave the silicon wafer at room temperature and wait for the temperature of the silicon wafer to drop to room temperature. Use an evaporation machine or a magnetron sputtering system to coat a layer of aluminum on the silicon wafer, and the thickness of the aluminum is about 140 nanometers. Aluminum serves as a sacrificial layer for finally peeling off the thin-film thermocouple 6 .

[015...

Embodiment 3

[0170] 1 cleaning silicon wafer

[0171] Clean the silicon wafer with piranha washing solution (H2SO4:H2O2=3:1) to remove organic impurities on the surface of the silicon wafer. Remove the wafer from the piranha solution and rinse the wafer with deionized water. Use a CDA air gun to dry the water on the surface of the silicon wafer.

[0172] 2 Plating sacrificial layer

[0173] Put the silicon wafer on the electric heating plate and heat it for 30 minutes, and the temperature of the electric heating plate is set at 150 degrees Celsius to dry the moisture on the surface of the silicon wafer. Leave the silicon wafer at room temperature and wait for the temperature of the silicon wafer to drop to room temperature. Use an evaporation machine or a magnetron sputtering system to coat a layer of aluminum on the silicon wafer, and the thickness of the aluminum is about 200 nanometers. Aluminum serves as a sacrificial layer for finally peeling off the thin-film thermocouple 6 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com