Ultrasonic Catalytic Oxidative Extraction Desulfurization Process for Light Cycle Oil

A light cycle oil, catalytic oxidation technology, applied in the petroleum industry, only multi-stage serial refining process treatment, hydrocarbon oil treatment, etc., can solve the problems of affecting the quality of fuel oil, increasing production costs, poor removal effect, etc., to achieve production Low cost, improved stability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

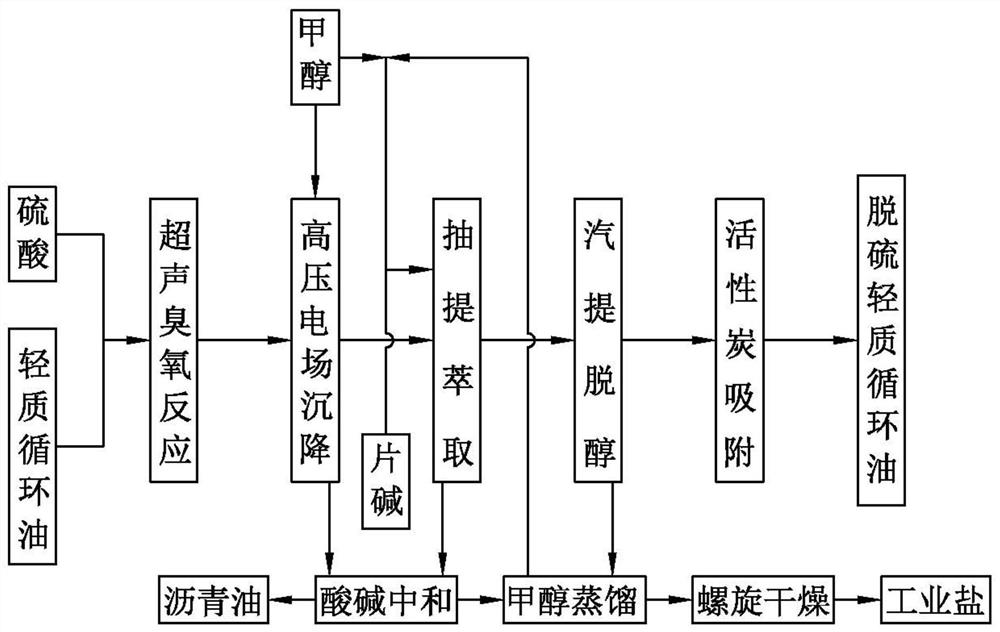

[0032] A light circulating oil ultrasonic catalytic oxidation extraction desulfurization process, comprising the following steps:

[0033] (1) Ultrasonic ozone reaction: carry out ozone reaction under ultrasonic conditions after mixing methanol, sulfuric acid and light circulating oil to be desulfurized;

[0034] (2) High-voltage electric field sedimentation: Methanol and the light circulating oil after the ozone reaction are mixed, and then sedimentation is carried out under the condition of high-voltage electric field to remove the sediment;

[0035] (3) Extraction and extraction: the mixed solution after removing the precipitate is extracted and extracted, and the oily part is then added with methanol for extraction and extraction several times; then the oily part is extracted and extracted several times with methanol and caustic soda to obtain Refined light cycle oil;

[0036] (4) stripping and dealcoholization: stripping and dealcoholizing the refined light circulating o...

Embodiment 2

[0047] The difference between this embodiment and the above-mentioned Embodiment 1 is:

[0048] In the step (1), the amount of sulfuric acid used is 0.5% of the volume of the light circulating oil to be desulfurized, and the frequency of ultrasonic waves is 20KHz.

[0049] In the step (2), the amount of methanol used is 5% of the volume of the light circulating oil to be desulfurized, and the voltage of the high-voltage electric field is 20KV.

[0050] In the step (4), the temperature of stripping and dealcoholization is 120°C; in the step (Y), the temperature of methanol distillation and recovery is 95°C, and in the step (Z), the temperature of the spiral drying is 150°C .

Embodiment 3

[0052] The difference between this embodiment and the above-mentioned Embodiment 1 is:

[0053] In the step (1), the amount of sulfuric acid used is 0.6% of the volume of the light circulating oil to be desulfurized, and the frequency of ultrasound is 25KHz.

[0054] In the step (2), the amount of methanol used is 6% of the volume of the light circulating oil to be desulfurized, and the voltage of the high-voltage electric field is 25KV.

[0055] In the step (4), the temperature of stripping and dealcoholization is 125°C; in the step (Y), the temperature of methanol distillation and recovery is 100°C, and in the step (Z), the temperature of the spiral drying is 160°C .

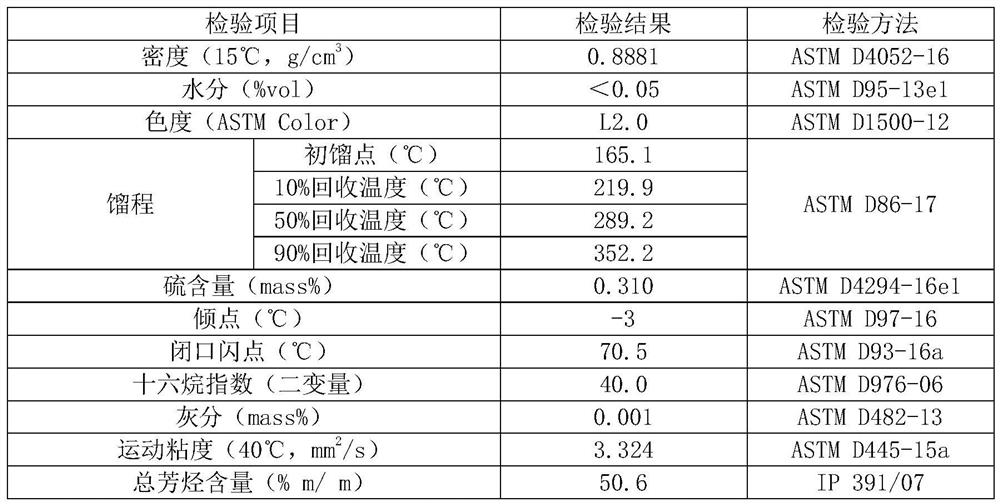

[0056] The inspection index of the light circulating oil to be desulfurized by the raw material of the present invention is shown in the following table:

[0057]

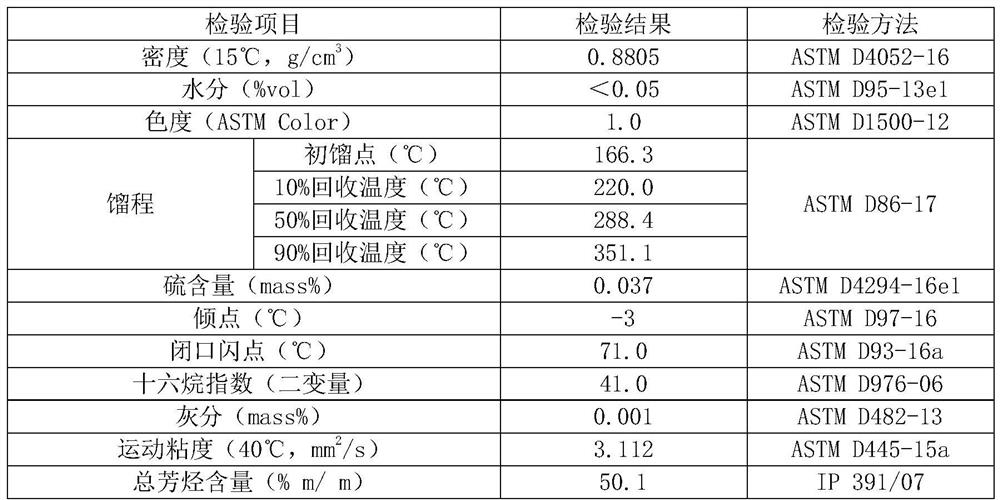

[0058] The inspection index of the product desulfurized light circulating oil after the process desulfurization of the present invention is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com