Preparation method of electromagnetic-driven hydrogel antifouling coating layer material

An antifouling coating and electromagnetic drive technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the complex process of magnetic hydrogel, large industrial application restrictions, and insufficient sample repetition rate To achieve good adhesion and desorption inhibition performance, low temperature and environment requirements, and the effect of inhibiting the adhesion of fouling organisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

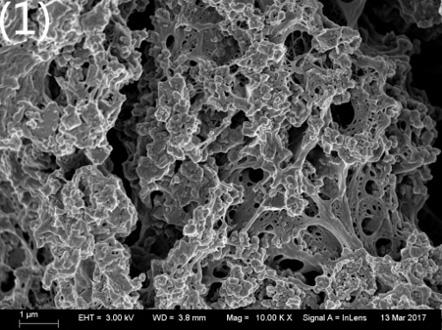

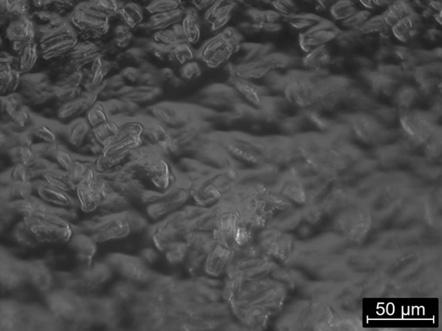

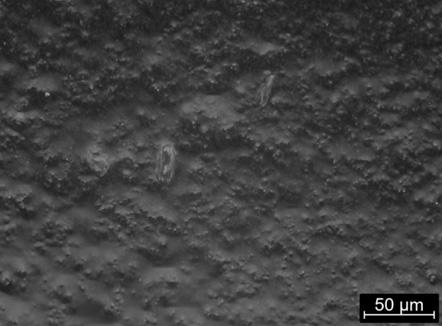

Image

Examples

preparation example Construction

[0031] A method for preparing an electromagnetically driven hydrogel antifouling coating material, the specific embodiment of which is: comprising the following preparation steps:

[0032] Step 1. Preparation of component A: According to the parts by weight, add 5-10 parts of polyvinyl alcohol resin, 50-90 parts of deionized water and 0.5-1 part of defoamer into the dispersion tank for high-speed dispersion for 8-12 minutes After the polyvinyl alcohol resin is completely dissolved in deionized water, add 15-50 parts of magnetic powder and 1-2 parts of thixotropic agent, and then add 30-40 parts of glass beads for sanding until the fineness of the above mixture is less than 80 μm. 100-mesh filter screen to filter out the material, spare;

[0033] Step 2. Preparation of component B: According to parts by weight, add 0.5-2 parts of binary aldehyde and 80-100 parts of deionized water into the dispersion tank for high-speed dispersion, and the concentration after dispersion is 0.5%...

Embodiment 1

[0046] Step 1. Preparation of component A: According to parts by weight, add 5 parts of polyvinyl alcohol resin with material type 1788, 50 parts of deionized water and 0.5 part of water-based silicone defoamer into the dispersion tank for high-speed dispersion for 8 minutes , the dispersion speed is 500rpm, after the polyvinyl alcohol resin is completely dissolved in deionized water, add 15 parts of ferric iron tetroxide with a fineness of 20 μm and 1 part of hydrophilic fumed silica, and then add glass with a diameter of 0.4mm Sand mill 30 parts of the beads until the fineness of the above mixture is less than 80 μm, filter the material with a 100-mesh filter screen, and set aside;

[0047] Step 2. Preparation of component B: According to parts by weight, add 0.5 parts of glutaraldehyde and 80 parts of deionized water into the dispersion tank and disperse at a high speed at a speed of 500 rpm. After the dispersion is uniform, the concentration of 0.5% is obtained. Binary ald...

Embodiment 2

[0051] Step 1. Preparation of component A: According to parts by weight, add 8 parts of polyvinyl alcohol resin, 70 parts of deionized water and 0.8 part of water-based polyether defoamer to the dispersion Disperse at high speed for 10 minutes in a cylinder, and the dispersion speed is 750rpm. After the polyvinyl alcohol resin is completely dissolved in deionized water, add 35 parts of magnetic powder mixed with nickel-zinc ferrite and zinc-chromium ferrite with a fineness of 35 μm. and 2 parts of hydrophilic fumed silica, and then add 35 parts of glass beads with a diameter of 0.7 mm for sand grinding until the fineness of the above mixture is less than 80 μm, filter the material with a 100-mesh filter, and set aside;

[0052] Step 2. Preparation of component B: According to parts by weight, add 1.4 parts of o-phthalaldehyde and 90 parts of deionized water into the dispersion tank and disperse at a high speed at a speed of 750 rpm. The concentration after the dispersion is uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com