Preparation and application of a kind of chlorine-containing phenolic resin nanomaterial

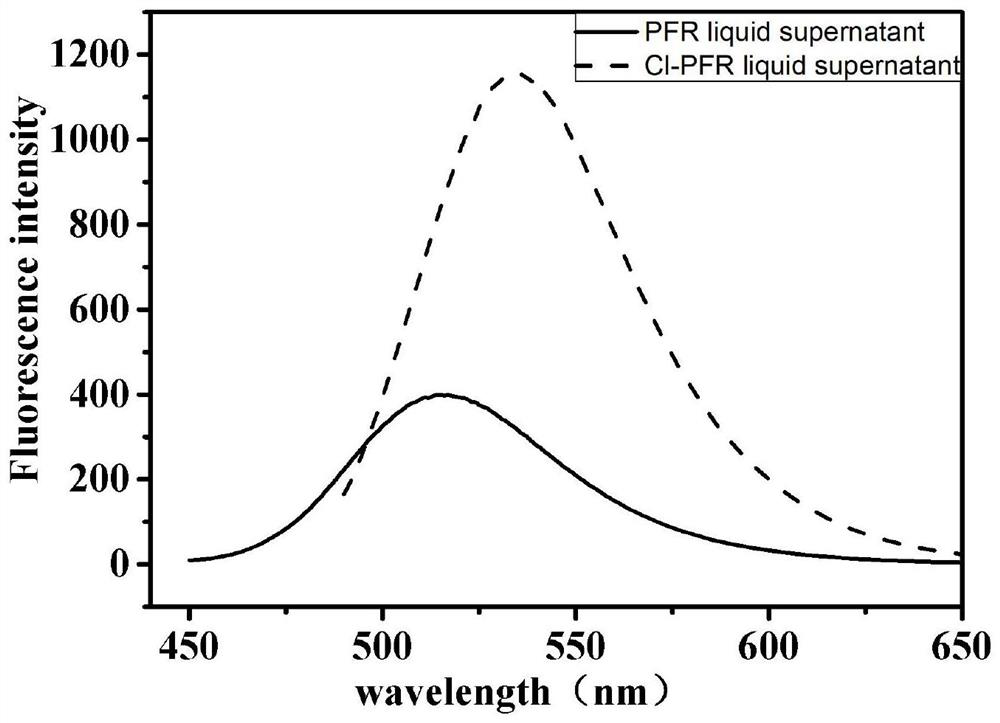

A technology of phenolic resin and nano-particles, which is applied in the analysis of materials, material excitation analysis, and material analysis through optical means, etc., can solve the problems affecting the sensitivity of fluorescent probes, low fluorescence intensity, low luminous efficiency, etc., and achieve strong fluorescence Emission intensity, simple synthesis steps, and the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] The preparation of chlorine-containing phenolic resin nanoparticles used in the present invention is realized through the following steps:

[0039] (1) Add 0.042g of hexamethylenetetramine, 0.15mmol of p-chlorophenol and 30mL of deionized water to a 50mL polytetrafluoroethylene autoclave, and conduct a hydrothermal reaction in an oven at 160°C for 6 hours.

[0040] (2) Take out the reacted solution and place it in a centrifuge tube, set the rotation speed at 11000 rpm, centrifuge for ten minutes, remove the precipitate, keep the supernatant, and dialyze in deionized water for three days.

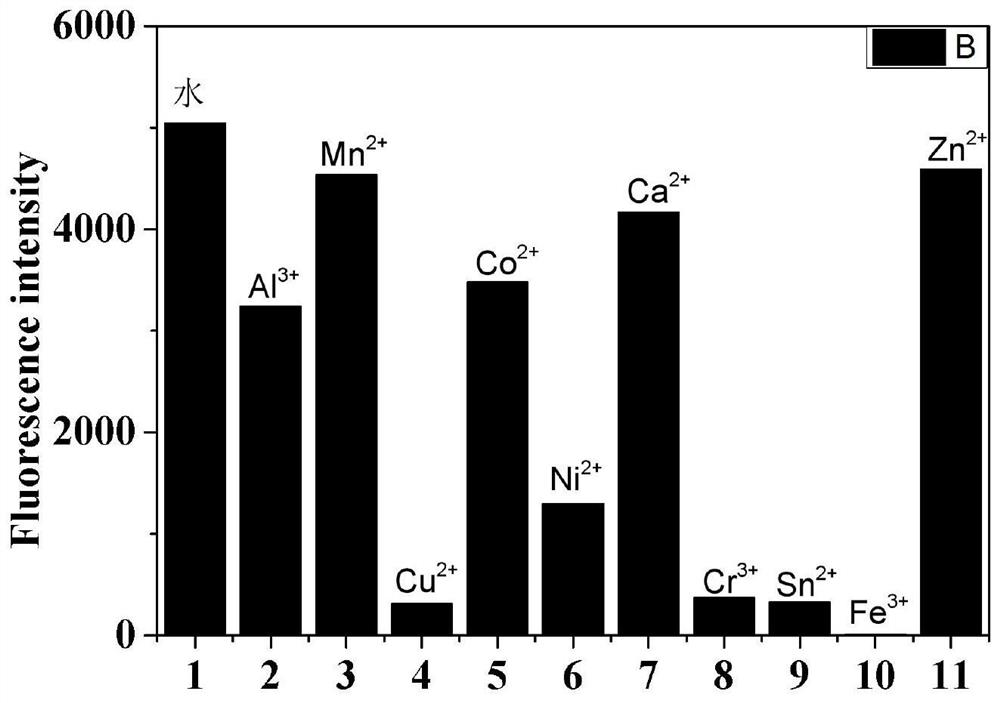

[0041] (3) Get 200uL of the nano particle sol described in (2) and add the solution of Fe3+, Al3+, Mn2+, Ni2+, Co2+, Fe2+, Zn2+, Ca2+, Sn2+, Cu2+, Cr2+, Fe2+ of 200uL respectively, then add 2mL to remove The deionized water was stirred evenly and allowed to stand for 3 minutes.

[0042] (4) Measure the fluorescence intensity of the above metal ion mixed solution with a fluorescence s...

example 2

[0045] (1) Add 100 uL of chlorinated phenolic resin nanoparticle sol into a 5ml centrifuge tube.

[0046](2) Take 2mL of the Fe3+ solution and add the above-mentioned doped chlorine-containing phenolic resin nanoparticles to form a mixed solution, and let it stand for 3 minutes, wherein the ferric ion concentration is controlled to 0-1mmol.

[0047] (3) Test the fluorescence intensity of the above-mentioned mixed solution with a fluorescence spectrophotometer, the excitation wavelength is 450nm, and record the fluorescence intensity change curve, such as Figure 4 shown;

[0048] (4) draw the curve that chlorine-containing phenolic resin nano-particle is along with the increase of Fe3+concentration weakens fluorescence intensity gradually, and it is fitted, obtain fitting formula y=-5106.22061x+4507.48327 (x is ferric ion concentration [ uM], y is the fluorescence intensity) such as Figure 5 shown;

[0049] (5) Take a certain amount of sample water, remove impurities throu...

example 3

[0053] (1) Add 100uL of the above-mentioned chlorine-containing phenolic resin nanoparticle sol in the test tube;

[0054] (2) 2mLFe3+ was added in the above-mentioned chlorine-containing phenolic resin nanoparticle solution, left standstill for 3 minutes, Fe3+concentration was controlled as 1mmol;

[0055] (3) Add 2 mL of ascorbic acid of different concentrations to the above mixed solution, and finally transfer to the quartz cuvette;

[0056] (4) Test the fluorescence intensity of the above-mentioned mixed solution with a fluorescence spectrophotometer, the excitation wavelength is 450nm, and record the fluorescence intensity change curve, such as Image 6 shown;

[0057] (5) draw the curve that the fluorescence intensity of mixed solution increases gradually along with the increase of ascorbic acid concentration, and it is fitted, obtain fitting formula y=71.5428x+1186.928 (x is ascorbic acid concentration [mM], y is fluorescence intensity) like Figure 7 shown;

[0058...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com