A kind of dermis care waterproof film-forming agent and preparation method thereof

A waterproof film-forming, leather technology, applied in leather surface treatment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. Durability, leather is easy to fade, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

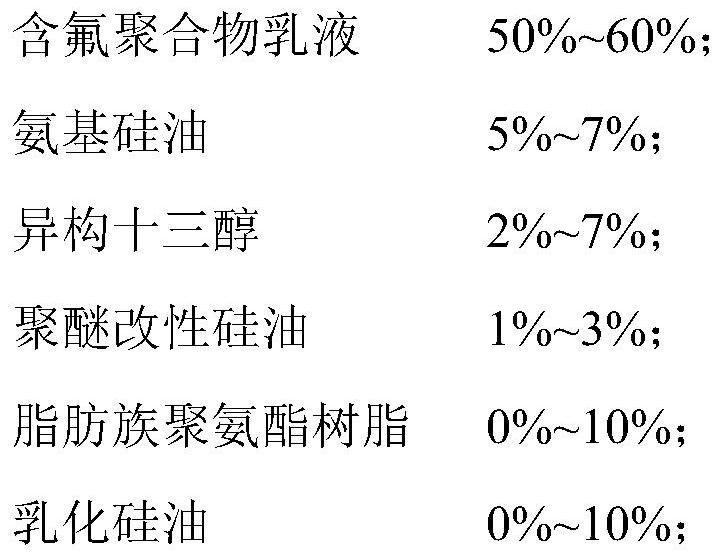

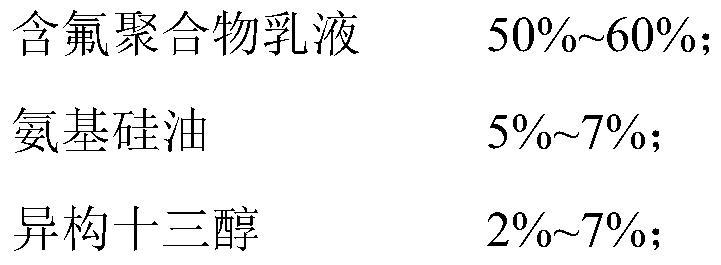

Image

Examples

preparation example Construction

[0028] The preparation method of the waterproof film-forming agent for leather care is to weigh the raw materials according to the above composition, and mix and stir to obtain the waterproof film-former for leather care.

[0029] Preferably, in the preparation method, the mixing and stirring is specifically placing the materials in a reaction kettle, heating to 80° C. to 90° C. under vacuum conditions, and mixing and stirring for 50 minutes to 70 minutes.

[0030] The usage method of this dermis care waterproof film-forming agent is to spray or smear the dermis care waterproof film-forming agent on the surface of dermis products.

[0031] Further, it is advisable to spray or smear the dosage of the waterproof film-forming agent for dermis care to evenly cover the surface of the dermis product to form a thin protective film layer.

Embodiment 1

[0034] Example 1 The raw materials and mass percentages of the leather care waterproof film-forming agent are shown in Table 1. The fluorine-containing polymer emulsion used in Example 1 is a perfluoroalkyl ethyl acrylate emulsion, and the ammonia value of the amino silicone oil is 0.27 mmol / g.

[0035] Table 1 embodiment 1 dermis care waterproof film-forming agent composition

[0036] raw material Mass percentage (%) Fluoropolymer Emulsion 50 Amino silicone oil 7 isotridecyl alcohol 2 Aliphatic polyurethane resin 10 Emulsified silicone oil 10 Polyether modified silicone oil 1 Deionized water 20

[0037] After the raw materials described in Table 1 were weighed according to the proportion, they were placed in a reaction kettle, heated to 85°C under vacuum conditions (0.01MPa~0.02MPa), stirred for 60min, then cooled to room temperature and discharged to obtain Example 1 Waterproof film former for dermal care.

[0038] W...

Embodiment 2

[0042] Example 2 The raw materials and mass percentages of the leather care waterproof film-forming agent are shown in Table 2. The used raw material of embodiment 2 is identical with embodiment 1 unless otherwise specified.

[0043] Table 2 embodiment 2 dermis care waterproof film-forming agent composition

[0044] raw material Mass percentage (%) Fluoropolymer Emulsion 60 Amino silicone oil 7 isotridecyl alcohol 3 Aliphatic polyurethane resin 1 Emulsified silicone oil 7 Polyether modified silicone oil 2 Deionized water 20

[0045] After the raw materials described in Table 2 were weighed according to the proportion, they were placed in a reaction kettle, heated to 85°C under vacuum conditions (0.01MPa~0.02MPa), stirred for 60min, then cooled to room temperature and discharged to obtain Example 2 Waterproof film former for dermal care. The product of Example 2 is a product aimed at dermal scrub. Genuine nubuck leathe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com