Preparation process of decorative plate containing polyurethane thermal insulation layer

A preparation process and decorative board technology, which is applied in construction, building structure, covering/lining, etc., can solve the problems of decorative boards such as low compressive performance, high flexibility and low strength, and easy to form scratches, so as to ensure firm adhesion Fixation, high support performance, and the effect of realizing flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The specific preparation process of the isolation support layer is as follows:

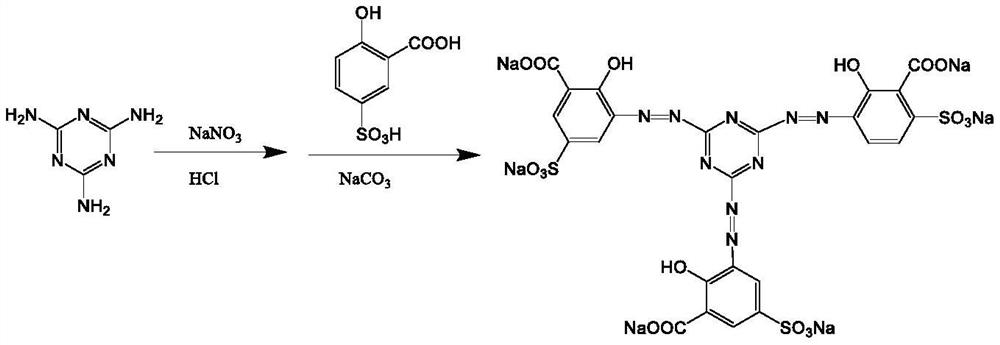

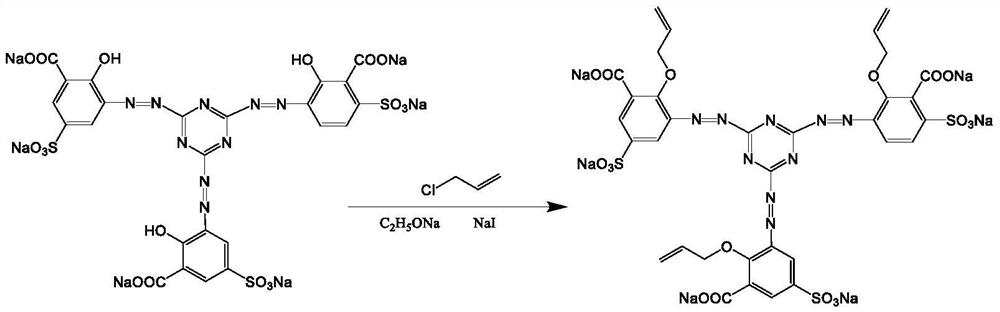

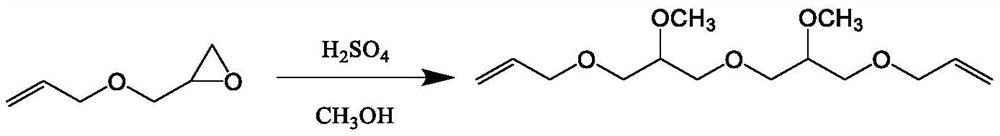

[0041] Step 1: Add 1kg melamine, 5L water and 1.81kg mass concentration of 16% hydrochloric acid solution into the reactor, heat to 85°C and stir to dissolve it, then cool to 8°C and add 624g mass concentration of 30% hydrochloric acid solution therein Sodium nitrate solution, control the temperature at 12°C and stir vigorously for 5 minutes, then keep the obtained solution at the same temperature and store it for later use, then add 945g of sodium carbonate, 130L of water and 6.09kg of 5-sulfosalicylic acid aqueous solution into the coupling bucket, and stir at the same time Add the above standby solution to it, keep it warm at 15°C for 2h, then add 1.23kg of sodium chloride therein, raise the temperature to 65°C and keep it warm for 5h, then filter and dry to obtain the conjugated sulfosalicylic acid triazine, The reaction structural formula is as follows; The product is carried out infra...

Embodiment 2

[0050] The specific preparation process of the isolation support layer is the same as that of Example 1, and the 5-sulfosalicylic acid used in the preparation process of Step 1 in Example 1 is replaced by p-hydroxysulfonic acid.

[0051] The limiting oxygen index of the isolation support layer is 32.8%, and the tensile strength is 41.36MPa. Add heavy calcium carbonate directly to the polymer. Due to the poor compatibility between the heavy calcium carbonate and the polymer, directly through physical stirring When mixed, the dispersion performance thereof is reduced, thereby affecting the overall tensile strength of the prepared isolation support.

Embodiment 3

[0053] The specific preparation process of the isolation support layer is the same as in Example 1, but the diene-based end-capping flexible agent is not prepared, and the monomer olefin-based sulfosalicylic acid triazine is directly used in the polymerization process in step 4 to carry out free radicals. Polymerization produces polymers.

[0054] The limiting oxygen index of the isolation support layer is 33.6%, and the tensile strength is 40.13MPa. The polymer is prepared by directly using olefinic sulfosalicylic acid triazine as a monomer. The obtained polymer has high rigidity, low flexibility, and good texture. brittle, resulting in a decrease in its tensile strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com