Nano modified inorganic mineral waterproof agent as well as preparation method and application thereof

An inorganic mineral and nano-modification technology, applied in the field of concrete structure protection and waterproof mortar, can solve the problems of high cost, poor weather resistance and durability, and decreased mechanical properties, and achieve the effect of low cost, good performance and good comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

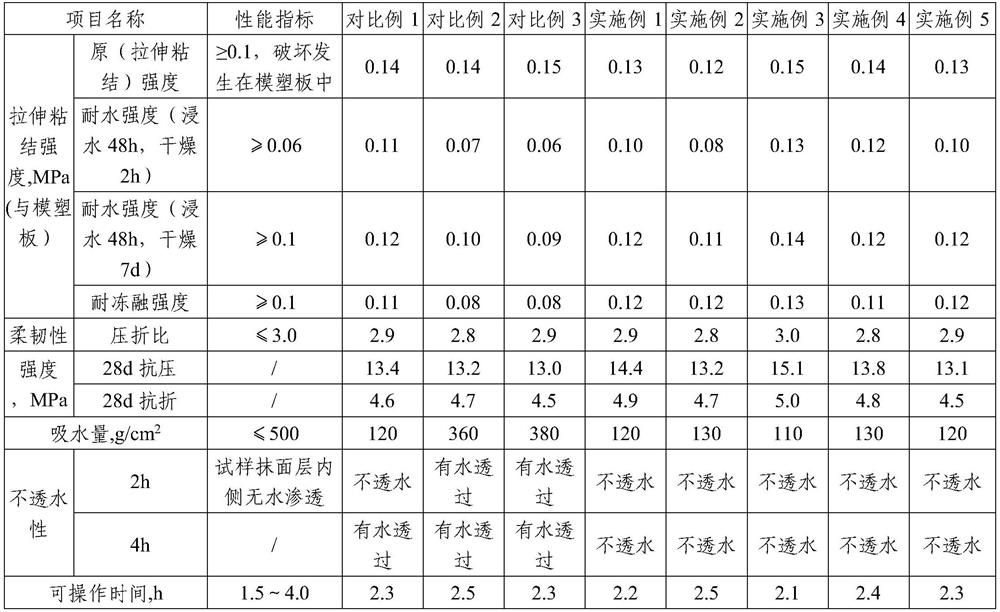

Examples

Embodiment 1

[0034] This embodiment provides a nano-modified inorganic mineral water repellent, the preparation method of which comprises the following steps:

[0035] Step 1: disperse 85 parts of fly ash into 200 parts of deionized water, and fully stir for 15 minutes to obtain a fly ash suspension;

[0036] Step 2: Add 2 parts of nano-graphene and 3 parts of nano-calcium stearate to the fly ash suspension, and stir for 20 minutes to obtain a mixed suspension;

[0037] Step 3: The above-mentioned mixed suspension and 0.2 parts of boric acid ester were mechanically activated and grafted in a planetary mill with a rotation speed of 500r / min for 6 hours, and the reaction temperature was controlled within the range of 80°C ± 10°C. After filtering Carry out low temperature drying to constant weight, drying temperature is 80 ℃. The dry matter is dispersed by high-speed stirring to obtain nano-modified inorganic mineral water repellent P1.

Embodiment 2

[0039] This embodiment provides a nano-modified inorganic mineral water repellent, the preparation method of which comprises the following steps:

[0040] Step 1: disperse 87 parts of heavy calcium powder into 240 parts of deionized water, and fully stir for 20 minutes to prepare heavy calcium powder suspension;

[0041] Step 2: Add 3 parts of nano-calcium stearate and 7 parts of nano-calcium carbonate to the heavy calcium powder suspension, and stir for 20 minutes to prepare a mixed suspension;

[0042] Step 3: The above-mentioned mixed suspension, 0.2 parts of stearic acid and 0.2 parts of titanate were subjected to mechanically activated grafting reaction for 8 hours in a planetary mill with a rotation speed of 450 r / min, and the reaction temperature was controlled at 70 ° C ± 10 Within the range of ℃, filter and dry at low temperature to constant weight, the drying temperature is 80 ℃. The dry matter is dispersed by high-speed stirring to obtain nano-modified inorganic mi...

Embodiment 3

[0044] This embodiment provides a nano-modified inorganic mineral water repellent, the preparation method of which comprises the following steps:

[0045] Step 1: Disperse 70 parts of fly ash and 25 parts of stone powder into 300 parts of deionized water and stir thoroughly for 10 minutes to prepare a mixed suspension of fly ash and stone powder;

[0046] Step 2: Add 5 parts of nano-calcium stearate to the mixed suspension of fly ash powder, and stir for 10 minutes to prepare the mixed suspension;

[0047] Step 3: The above-mentioned mixed suspension and 0.3 parts of aluminate coupling agent were subjected to mechanically activated grafting reaction in a ball mill with a rotation speed of 150 r / min for 8 hours, and the reaction temperature was controlled within the range of 80 ° C ± 10 ° C. After filtration Carry out low-temperature drying to constant weight, and the drying temperature is 70°C. The dry matter is dispersed by high-speed stirring to obtain nano-modified inorgan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com