Preparation method of copper-based superhydrophobic surface structure

A super-hydrophobic surface, copper-based technology, used in devices for coating liquids on surfaces, special surfaces, pre-treated surfaces, etc., can solve the problems of easy peeling of surface coatings, poor performance, and time-consuming, and achieve the preparation cycle. The effect of shortening, reducing the preparation cost and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

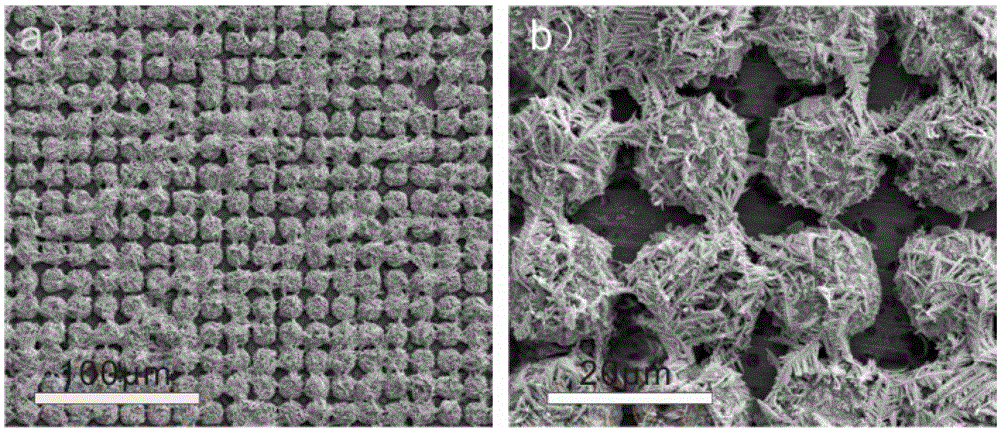

[0026] The preparation method of a copper-based superhydrophobic surface structure designed by the present invention, the main steps of the method include:

[0027] The first step is to pre-treat the metal copper substrate;

[0028] In the second step, a layer of photoresist is spin-coated on the surface of the copper substrate processed in the first step, and the photoresist layer attached to the surface of the copper substrate forms an ordered porous array template through photolithography;

[0029] In the third step, the copper substrate with the ordered porous array template prepared in the second step is used as the positive electrode and immersed in CuSO 4 The formation of the primary battery in the solution reacts for 4 to 8 minutes;

[0030] The fourth step, the copper substrate after the reaction of the third step galvanic cell is immersed in AgNO 3 Reaction in solution for 30~70s;

[0031] In the fifth step, the copper substrate after the reaction in the fourth step is subject...

Embodiment 1

[0043] The first step is to immerse the copper substrate in 20mmol / L dilute hydrochloric acid for 20 seconds at room temperature and then take it out. After repeated several times, clean the surface with deionized water, and then use acetone, absolute ethanol, and deionized water for ultrasonic cleaning for 10 minutes. ;

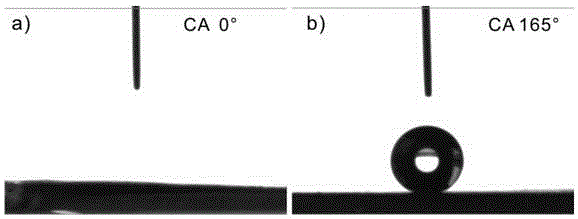

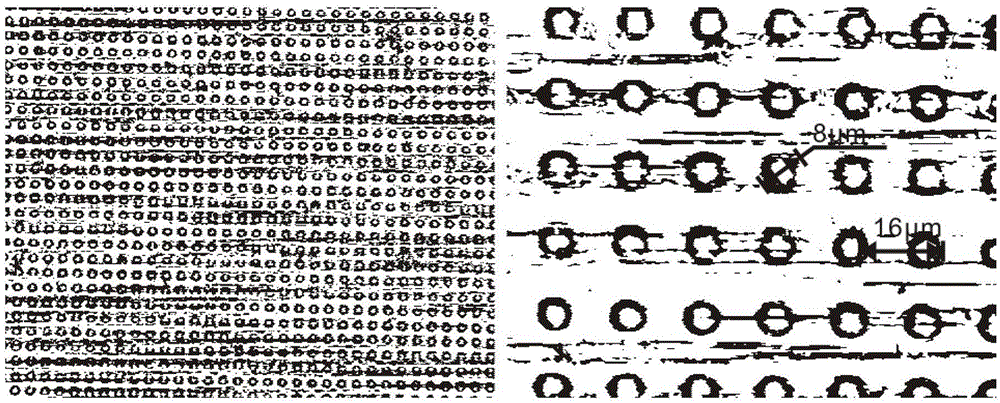

[0044] In the second step, a layer of photoresist is spin-coated on the surface of the copper substrate pretreated in the first step, and an ordered porous array template is formed on the surface of the copper substrate after ultraviolet exposure. The pore size of the ordered porous array template is 8μm and the pitch is 16μm, such as figure 1 Shown

[0045] Step 3: Prepare 0.2mol / L CuSO 4 Solution, seal the part of the copper substrate obtained in the second step that is exposed to the outside and the disordered porous array template, and then use the copper substrate as the positive electrode, and the zinc flake of equal size as the negative electrode, so that ...

Embodiment 2

[0050] The first step is to immerse the copper substrate in 20mmol / L dilute hydrochloric acid for 20 seconds at room temperature and then take it out. After repeated several times, clean the surface with deionized water, and then use acetone, absolute ethanol, and deionized water for ultrasonic cleaning for 10 minutes. ;

[0051] In the second step, a layer of photoresist is spin-coated on the surface of the copper substrate pretreated in the first step, and an ordered porous array template is formed on the surface of the copper substrate after ultraviolet exposure. The pore size of the ordered porous array template is 8μm and the pitch is 12μm, such as figure 1 Shown

[0052] The third step is to prepare 0.5mol / L CuSO 4 Solution, seal the part of the copper substrate obtained in the second step that is exposed to the outside and the disordered porous array template, and then use the copper substrate as the positive electrode and the zinc sheet as the negative electrode, so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com