Anti-yellowing antibacterial polypropylene plastic for automobile decorations

An antibacterial polypropylene and anti-yellowing technology, applied in the field of plastics, can solve the problems of insufficient mechanical properties, yellowing, mildew, etc., and achieve the effect of low hydrophilic and lipophilic balance, slowing down the aging speed, and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

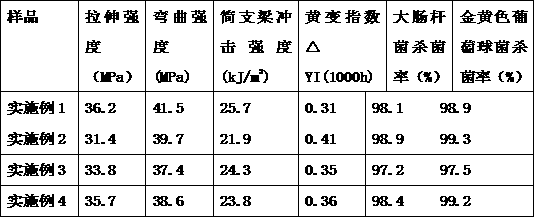

Examples

Embodiment 1

[0027] An anti-yellowing and antibacterial polypropylene plastic for automobile accessories, comprising the following raw materials in parts by weight: 100 parts of polypropylene, 30 parts of polystyrene, 15 parts of nitrile rubber, 20 parts of nano-calcium carbonate, 2 parts of titanium dioxide, and shell powder 8 parts, 1.5 parts of octaphenyl clathrate silsesquioxane, 2 parts of polyoxyethylene stearate, 1 part of compound antibacterial agent, 1.5 parts of coupling agent, 1 part of methyl tributylketoxime silane crosslinking agent , 1.5 parts of 1010 anti-aging agent, 1.5 parts of plasticizer, 1 part of stabilizer and 2 parts of processing aid.

[0028] The composite antibacterial agent is composed of lanthanum oxide and nanometer silver oxide with a mass ratio of 1:2.

[0029] The coupling agent is composed of sodium lignosulfonate and glycidyltriethoxysilane with a mass ratio of 1.5:1.

[0030] The plasticizer is composed of rapeseed fatty acid alkanolamide borate and ca...

Embodiment 2

[0038] An anti-yellowing and antibacterial polypropylene plastic for automobile accessories, comprising the following raw materials in parts by weight: 100 parts of polypropylene, 25 parts of polystyrene, 20 parts of nitrile rubber, 15 parts of nano-calcium carbonate, 4 parts of titanium dioxide, and shell powder 10 parts, 2.5 parts of octaphenyl clathrate silsesquioxane, 1 part of polyoxyethylene stearate, 1.5 parts of compound antibacterial agent, 2 parts of coupling agent, 1.5 parts of vinyl tributylketoxime silane crosslinking agent , 0.5 parts of 1076 anti-aging agent, 2 parts of plasticizer, 1.5 parts of stabilizer and 3 parts of processing aid.

[0039] The composite antibacterial agent is composed of lanthanum oxide and nanometer silver oxide with a mass ratio of 1:3.

[0040] The coupling agent is composed of sodium lignosulfonate and glycidyltriethoxysilane with a mass ratio of 1:1.

[0041] The plasticizer is composed of rapeseed fatty acid alkanolamide borate and ...

Embodiment 3

[0049]An anti-yellowing and antibacterial polypropylene plastic for automotive accessories, comprising the following raw materials in parts by weight: 100 parts of polypropylene, 20 parts of polystyrene, 15 parts of nitrile rubber, 20 parts of nano-calcium carbonate, 3 parts of titanium dioxide, and shell powder 7 parts, 3 parts of octaphenyl clathrate silsesquioxane, 1.5 parts of polyoxyethylene stearate, 0.5 parts of compound antibacterial agent, 1 part of coupling agent, 2 parts of dimethyldibutylketoxime silane crosslinking agent 1 part, 1 part of 1010 anti-aging agent, 1 part of plasticizer, 2 parts of stabilizer and 2 parts of processing aid.

[0050] The composite antibacterial agent is composed of lanthanum oxide and nanometer silver oxide with a mass ratio of 1:2.

[0051] The coupling agent is composed of sodium lignosulfonate and glycidyltriethoxysilane with a mass ratio of 1:1.

[0052] The plasticizer is composed of rapeseed fatty acid alkanolamide borate and cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com