An antistatic non-flammable ground material and its preparation method

A ground material and anti-static technology, applied in the field of floor materials, can solve the problems of complex metal aggregate type process, easy to generate sparks, flammable and explosive, etc., and achieve long-term and high-efficiency electrical conductivity, excellent electrical conductivity, and preparation method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

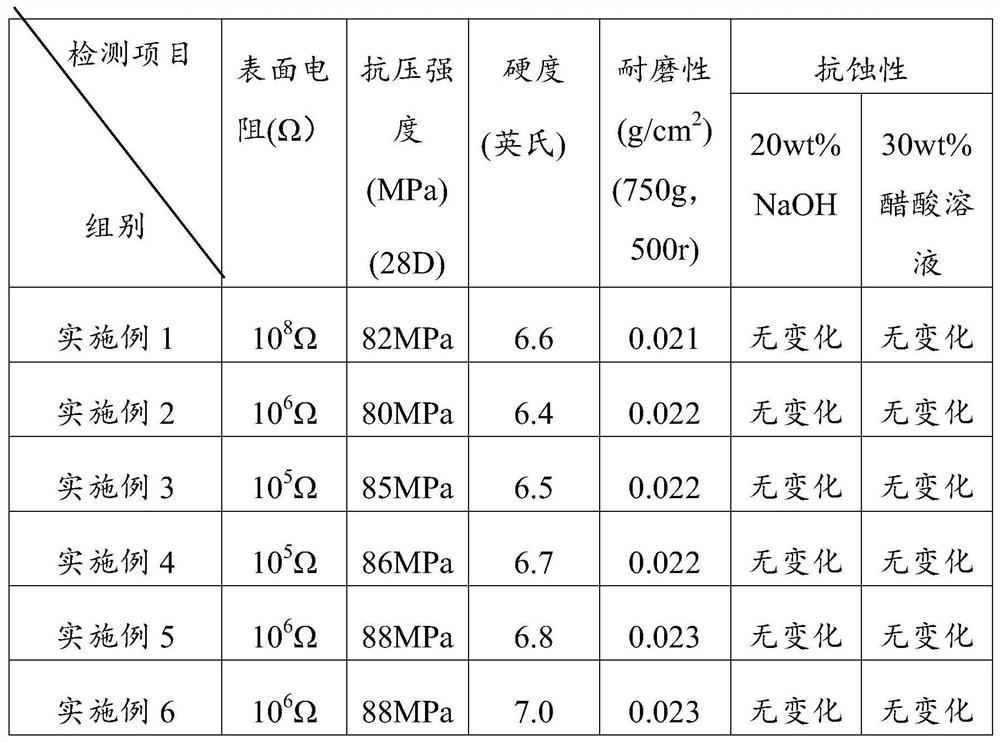

Examples

Embodiment 1

[0026] Anti-static non-flammable ground material, including the following raw materials in percentage by weight: 60% of dolomite, 34% of cement, 5% of metal conductive pearl powder, 0.2% of water reducing agent and 0.8% of anti-alkali agent, the particle size of the dolomite 0.15-0.5mm.

[0027] The preparation method of the above-mentioned antistatic non-flammable ground material comprises the following steps:

[0028] (1) Modified metal conductive pearl powder:

[0029] First prepare metal conductive pearlescent powder: the metal conductive pearlescent powder is titanium dioxide coated muscovite, the preparation process of the metal conductive pearlescent powder is: weigh muscovite, carry out wet grinding, obtain mica powder slurry, add titanyl sulfate , heated, hydrolyzed, then washed with water, dehydrated, dried and roasted at 800°C, and pulverized to obtain metal conductive pearlescent powder;

[0030] Take an aqueous silicone emulsion, add 4 times the weight of water ...

Embodiment 2

[0034] Anti-static non-flammable ground material, including the following raw materials in percentage by weight: 64% of dolomite, 30% of cement, 5% of metal conductive pearl powder, 0.25% of water reducing agent and 0.75% of anti-alkali agent, the particle size of the dolomite 0.4-2mm.

[0035] The preparation method of the above-mentioned antistatic non-flammable ground material comprises the following steps:

[0036] (1) Modified metal conductive pearl powder:

[0037] First prepare metal conductive pearlescent powder: the metal conductive pearlescent powder is titanium dioxide coated muscovite, the preparation process of the metal conductive pearlescent powder is: weigh muscovite, carry out wet grinding, obtain mica powder slurry, add titanyl sulfate , heated, hydrolyzed, then washed with water, dehydrated, dried and roasted at 900°C, and crushed to obtain metallic conductive pearlescent powder;

[0038]Take an aqueous silicone emulsion, add 4 times the weight of water to...

Embodiment 3

[0042] Anti-static non-flammable ground material, including the following raw materials in percentage by weight: 60% of dolomite, 31.2% of cement, 8% of metal conductive pearl powder, 0.2% of water reducing agent and 0.6% of anti-alkali agent, the particle size of the dolomite 0.3-3.5mm.

[0043] The preparation method of the above-mentioned antistatic non-flammable ground material comprises the following steps:

[0044] (1) Modified metal conductive pearl powder:

[0045] First prepare metal conductive pearlescent powder: the metal conductive pearlescent powder is iron oxide coated muscovite, the preparation process of the metal conductive pearlescent powder is: take muscovite, carry out wet grinding, obtain mica powder slurry, add ferric sulfate solution , hydrolysis coating, washing, dehydration, drying at 105°C, and roasting at 600°C to obtain the metal conductive pearl powder; the iron oxide coating rate of the metal conductive pearl powder is 75%

[0046] Take an aqueo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com