Preparation method of copper and iron immiscible alloy

An immiscible alloy, copper-iron technology, applied in the field of preparation of copper-iron immiscible alloy, can solve the problems of high second phase volume fraction, high production cost, small macro segregation, etc. Increased nucleation rate and microstructure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

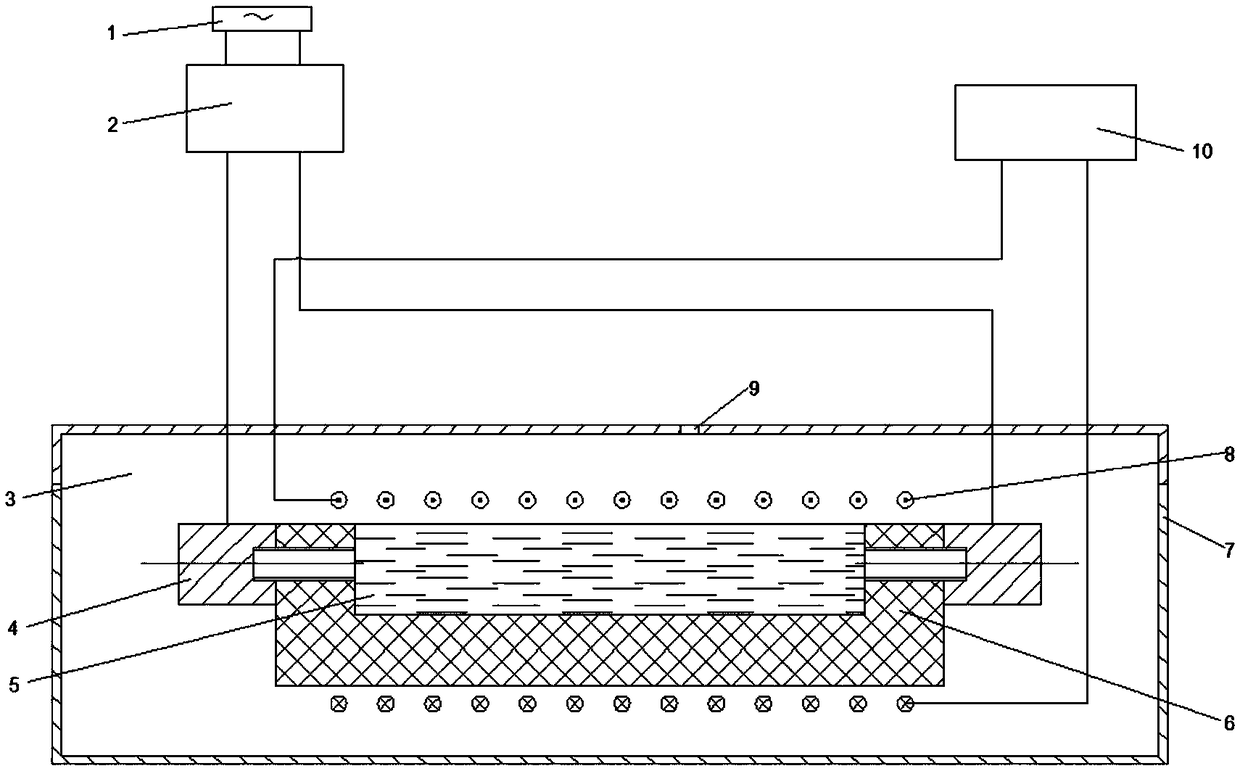

[0018] Such as figure 1 Shown, the preparation method that the present invention prepares copper-iron refractory alloy is:

[0019] The first step: place the boron nitride crucible 6 in the vacuum box 7 of the CW-30P high-frequency induction heating furnace, and then put the copper-iron sample 5 with a mass ratio of 85:15 into the boron nitride crucible 6, The boron nitride crucible 6 is connected to the molybdenum electrode 4, and the vacuum box 7 of the GW-30P high-frequency induction heating furnace is evacuated to 2×10 -4 Pa, turn on the high-frequency induction heating power supply 10, heat the copper-iron sample to 1400°C, melt all the copper-iron sample pieces 5, and keep the temperature for 10 minutes;

[0020] In the second step, an electric pulse is applied to the copper-iron sample 5 after heat preservation, and the action time is 10 minutes. First, the pulse power supply 2 is started, and then the output voltage of the pulse power supply 2 is adjusted to 60V, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com