Preparation method of wrinkly nano-rGO composite material, and preparation method of wrinkly nanometer metal oxide

A composite material and nano-metal technology, which is applied in the field of preparation of metal oxide nano-materials, can solve the problems of non-sustainability and batch size, high requirements for experimental conditions, complicated and difficult operations, etc., and achieves good potential for subsequent related analysis applications. , The effect of easy availability of raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

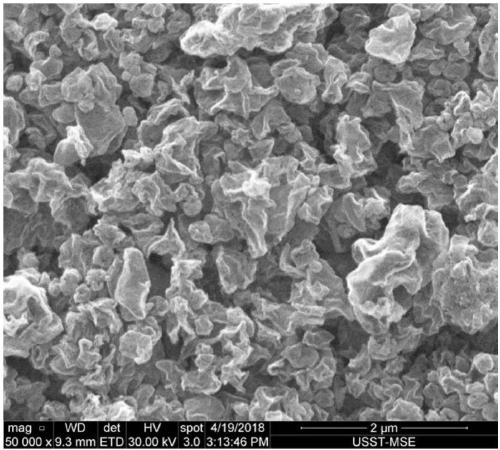

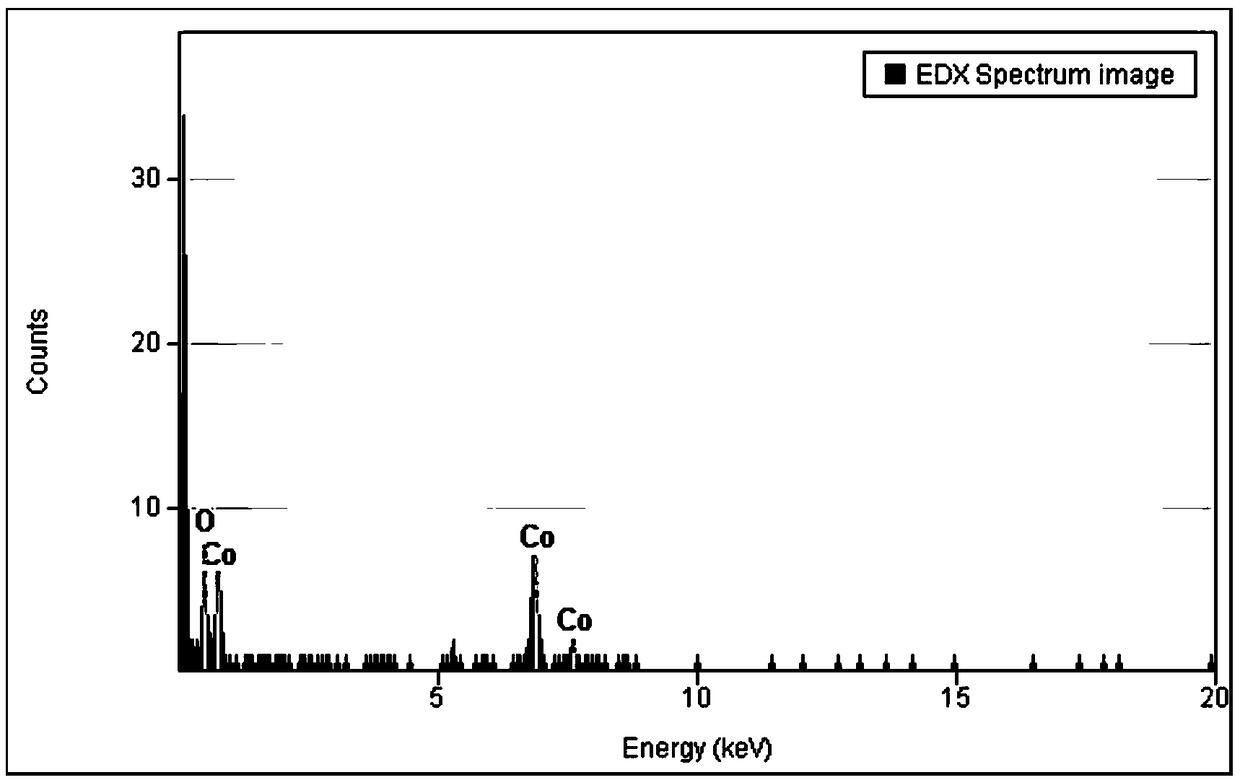

[0036] combine Figures 1 to 3 As shown, the preparation method of a wrinkled nano-rGO composite material provided in this embodiment specifically includes the following steps:

[0037] (1) Put 30ml of GO with a concentration of 10mg / ml and 250ml of deionized water in a beaker, and ultrasonically stir for 1min or magnetically stir for 5min at room temperature to make a GO aqueous dispersion; weigh 600mg of CoCl 2 ·6H 2 O solid was dissolved in 20ml deionized water; the prepared metal salt solution was mixed with GO aqueous dispersion, and magnetically stirred for 2h to obtain GO and CoCl 2 ·6H 2 O concentration ratio is a mixed solution of 1:2;

[0038] (2) Heat the tube reactor to 700°C, then atomize the mixture into droplets through an ultrasonic nebulizer, and then pump the droplets to the tube reactor through a vacuum pump, where the droplets are dried at high temperature in the tube reactor. Decompose and crystallize to form solid particles and adsorb to the collectio...

Embodiment 2

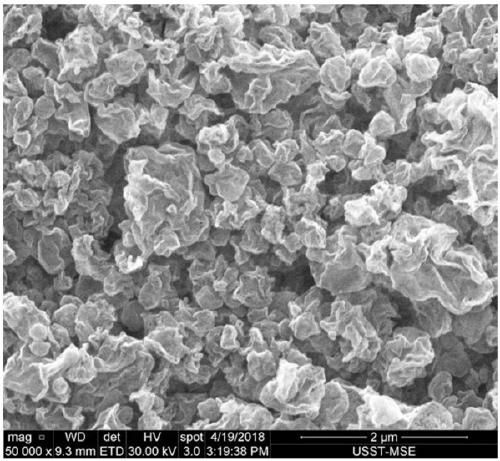

[0041]combine Figure 4 As shown, this example is the same as Example 1, the only difference is that this example provides a method for preparing a wrinkled nano-metal oxide, which specifically includes the following steps: the wrinkled nano-Co obtained in Example 1 3 o 4 The / rGO composite material is put into a crucible and calcined together with the crucible in a tubular reactor under an air atmosphere. The calcination process is as follows: after heating from room temperature to 400 °C at a heating rate of 10 °C / min, heat preservation at 400 °C After 3h, after cooling to room temperature with the furnace, the wrinkled nano-Co 3 o 4 powder material.

Embodiment 3

[0043] combine Figure 5 As shown, this example is the same as Example 1, the only difference is that this example provides a method for preparing a wrinkled nano-metal oxide, which specifically includes the following steps: the wrinkled nano-Co obtained in Example 1 3 o 4 The / rGO composite material is put into the crucible, and is calcined together with the crucible in the tubular reactor under the air atmosphere. The calcination process is as follows: 2 After heating from room temperature to 400°C at a heating rate of 1°C / min under atmosphere, heat preservation treatment at 400°C for 1 hour, then heat preservation at 400°C for 1 hour in air atmosphere, and finally cool naturally to room temperature in air cooling, and then obtain Wrinkled nano-Co with wrinkled paper-like microstructure 3 o 4 powder material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com