Graphene-rare earth-lanthanum reinforced Al-Si-Mg cast aluminum alloy and preparation method thereof

A technology for casting aluminum alloy and graphene, applied in the field of aluminum alloy, can solve the problem of high cost, achieve the effects of low casting cost, improved mechanical properties, and improved comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

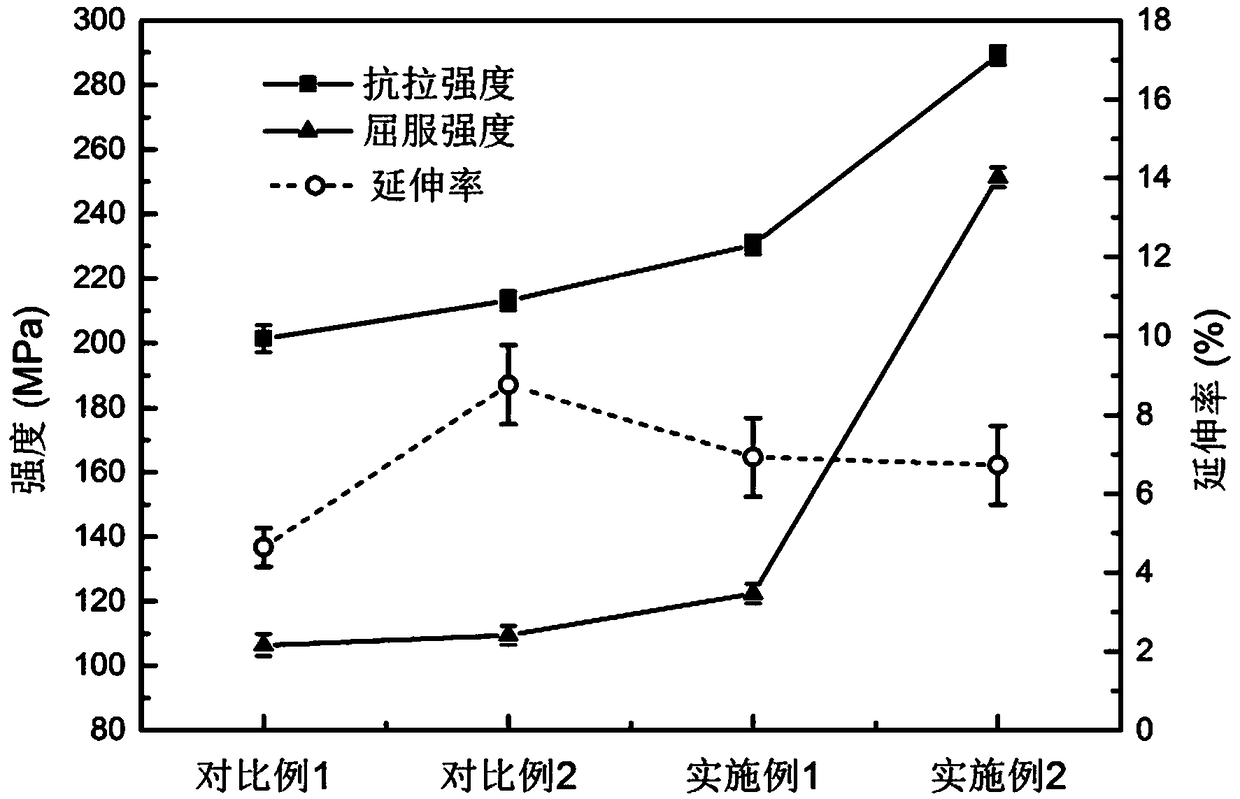

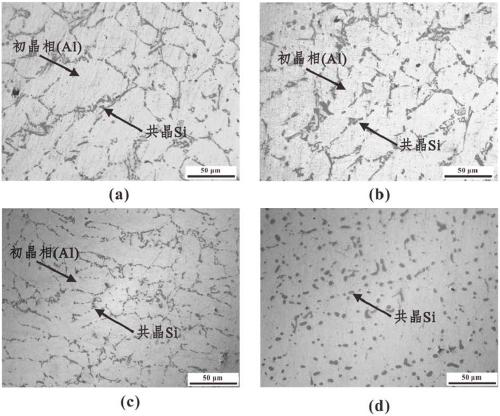

Examples

Embodiment 1

[0060] This example intends to prepare 70g of Al-Si-Mg cast aluminum alloy. The raw materials and mass percentages are as follows: graphene addition is 0.003wt.%, cerium addition is 0.4wt.%, silicon 7.0wt.%, magnesium 0.43wt.%, iron 0.02wt.%, zinc 0.03wt.%, manganese 0.02wt.%, titanium 0.02wt.%, zirconium 0.03wt.%, beryllium 0.01wt.%, tin 0.03wt.%, lead 0.02wt. .%, aluminum balance; the specific preparation method steps are as follows:

[0061] Step 1: Weigh each component raw material according to weight percentage;

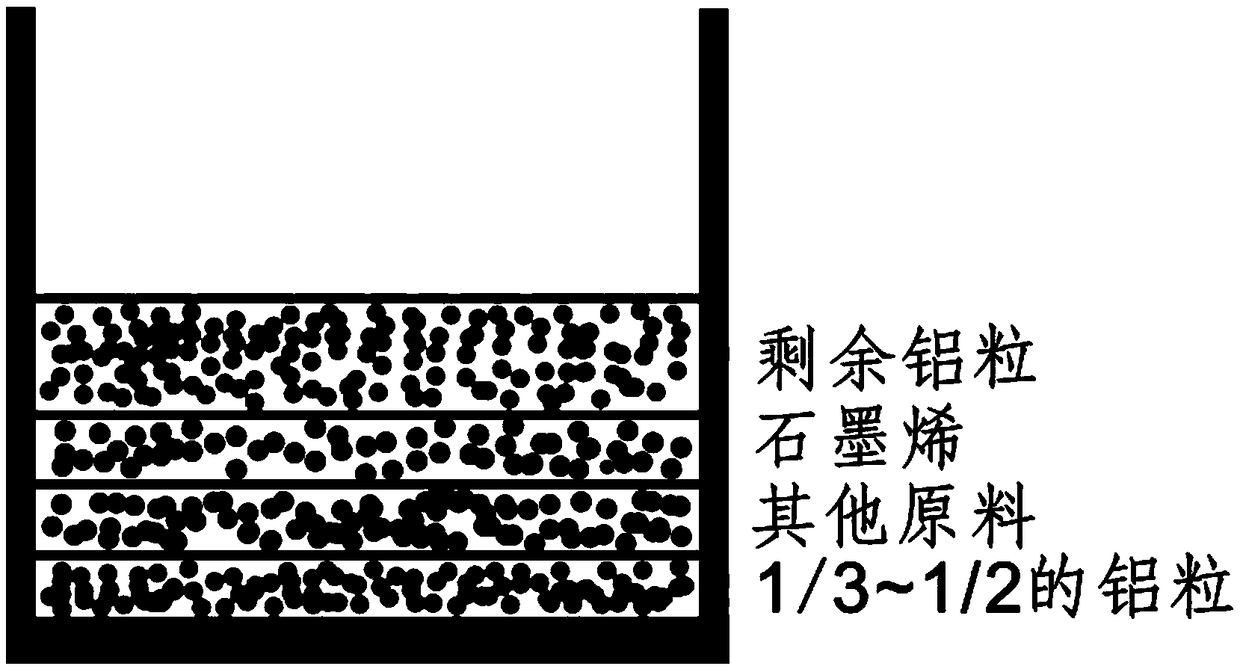

[0062] Step 2: Lay a layer of aluminum particles on the bottom of the crucible of the smelting furnace. The aluminum particles completely cover the bottom of the crucible without any gaps. The amount is 1 / 3 to 1 / 2 of the total amount of aluminum particles. Then, other than aluminum particles and graphene The raw material particles are laid, and finally graphene and the remaining aluminum particles are laid in sequence so that the aluminum particles completely cover ...

Embodiment 2

[0068] This example intends to prepare 70g of Al-Si-Mg cast aluminum alloy. The raw materials and mass percentages are as follows: graphene addition is 0.003wt.%, cerium addition is 0.4wt.%, silicon 7.0wt.%, magnesium 0.43wt.%, iron 0.02wt.%, zinc 0.03wt.%, manganese 0.02wt.%, titanium 0.02wt.%, zirconium 0.03wt.%, beryllium 0.01wt.%, tin 0.03wt.%, lead 0.02wt .%, aluminum balance.

[0069] The specific preparation method steps are as follows:

[0070] Step 1: Weigh each component raw material according to weight percentage;

[0071] Step 2: Lay a layer of aluminum particles on the bottom of the crucible of the smelting furnace. The aluminum particles completely cover the bottom of the crucible without gaps. The amount is 1 / 3 to 1 / 2 of the total amount of aluminum particles. Then, other than aluminum particles and graphene Spread the raw material particles, and finally layer graphene and the remaining aluminum particles in sequence, so that the aluminum particles completely cover t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com