High-intensity, high-toughness and corrosion-resistant titanium alloy and preparation method thereof

A high-strength, high-toughness, titanium alloy technology, applied in the field of alloys, can solve the problems of marine equipment service safety, hidden dangers in reliability, low plasticity and fracture toughness, etc. The effect of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

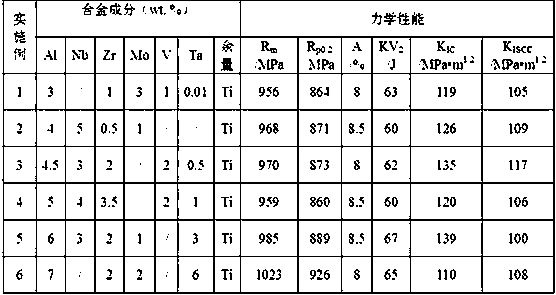

Examples

preparation example Construction

[0021] The preparation of the high-strength and high-toughness corrosion-resistant titanium alloy of the present invention comprises the following steps:

[0022] Step 1: Alloy composition ingredients: niobium, molybdenum, vanadium, and tantalum elements are added in the form of master alloys, zirconium and aluminum elements are added in the form of pure metals, according to the preset formula, that is, α-stable element Al: 3.0~7.0%, β-stable elements (Mo+Nb+V): 2.0~6.0%, Ta: 0.01~6.0%; neutral element Zr: 0.5~3.5%, weigh the ingredients, mix them thoroughly, and press them into electrodes.

[0023] Step 2: Ingot smelting: The ingot is prepared by vacuum consumable arc melting technology, and the pre-melting vacuum degree should reach 1Pa. In order to ensure uniform alloy composition, the number of smelting times is ≥ 3 times, and the arcing stage of ingot smelting is controlled at 2 -6min or so, the current in the normal smelting stage is above 2000A, and the time is 15-20min...

Embodiment 1

[0027] Example 1: Ti-3Al-1Zr-3Mo-1V-0.01Ta alloy

[0028] According to the mass percentage of each element composition, the element composition is weighed and proportioned; each element composition and its mass percentage are as follows: 3wt.% aluminum element, 3wt.% Mo element, 1wt.% zirconium element, 1wt.% Vanadium element, 0.01wt.% tantalum element, and the balance is industrial grade 1 sponge titanium; after weighing, it is melted into an alloy ingot three times by mixing materials, pressing electrode rods, and vacuum consumable electric arc furnace. T β +150°C blanking, α+β phase zone forging into forgings, rolling into wide sheets with different thicknesses by hot and cold rolling mills. After being treated by the heat treatment system, the properties of the alloy material are shown in Table 1.

Embodiment 2

[0029] Example 2: Ti-4Al-5 Nb -0.5Zr -1Mo alloy

[0030] According to the mass percentage of each element composition, the element composition is weighed and proportioned; each element composition and its mass percentage are as follows: 4wt.% aluminum element, 1wt.% Mo element, 0.5wt.% zirconium element, 5wt.% Niobium element, the balance is industrial grade 1 sponge titanium, after weighing, it is melted into alloy ingot three times by mixing materials, pressing electrode rods, and vacuum consumable electric arc furnace. via T β +150°C blanking, α+β phase zone forging into forgings, rolling into wide sheets with different thicknesses by hot and cold rolling mills. After being treated by the heat treatment system, the properties of the alloy material are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com