Lithium-ion-conducting composite material, comprising at least one polymer and lithium-ion-conducting particles

一种复合材料、传导粒子的技术,应用在锂蓄电池、电池、可持续制造/加工等方向,能够解决晶界电导率下降等问题,达到提高电导率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

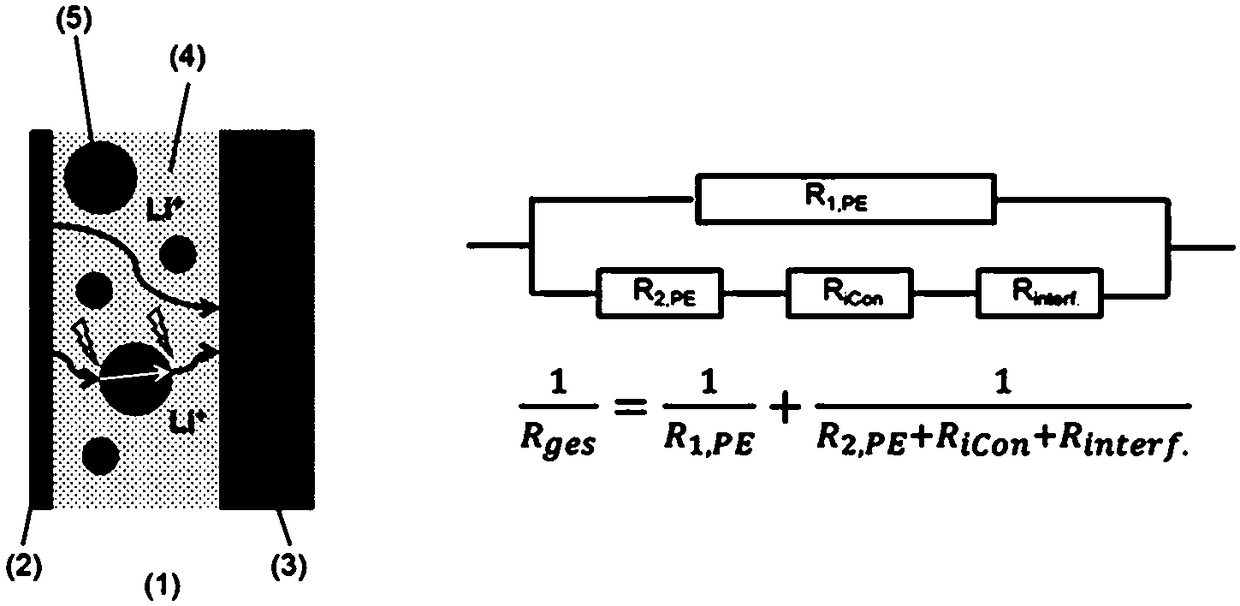

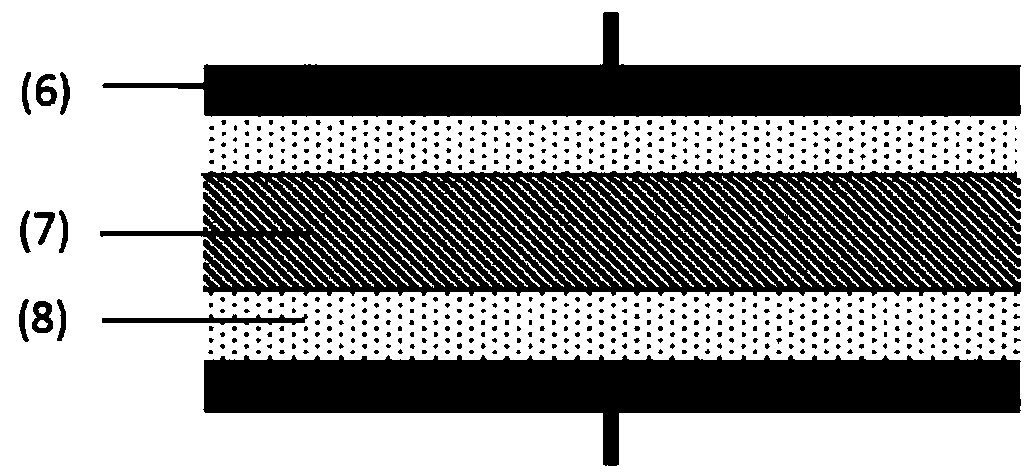

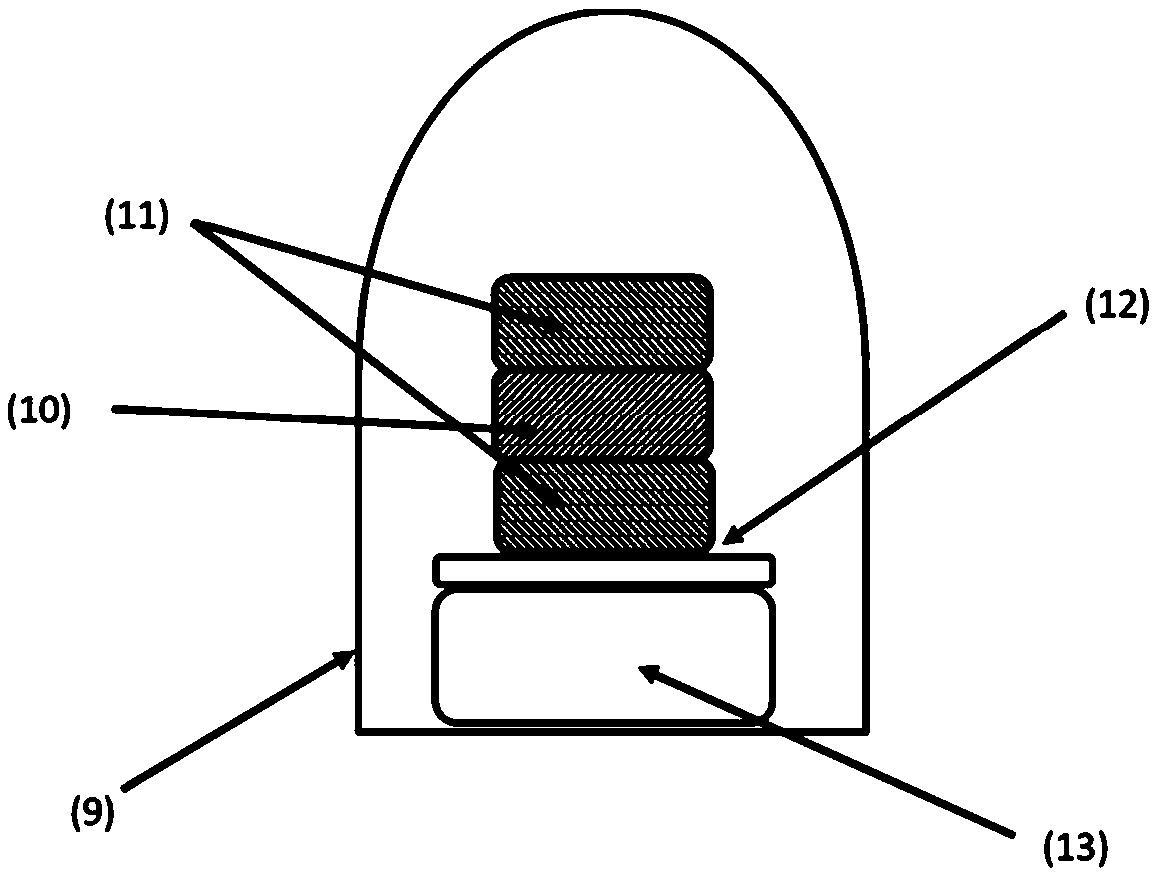

Problems solved by technology

Method used

Image

Examples

Embodiment

[0101] Silanization with GLYEO:

[0102] 10.0 g lithium lanthanum zirconium oxide (LLZO) powder (d 50 =0.4μm, specific surface area: 2.5m 2 / g) was dispersed in 75 ml of isopropanol. Dissolve the particle suspension with 12 ml of 25% NH by stirring 4 OH aqueous solution mixed. Then 0.9 ml of 3-glycidyloxypropyltrimethoxysilane was added and the reaction mixture was left under stirring for 24 hours. After the reaction was complete, the solid was isolated by centrifugation, redissolved in isopropanol, washed and centrifuged again. Finally, the wet residue was dried in a drying oven at 65 °C for 5 h.

[0103] Grind in PEG 400:

[0104] 70.0 g lithium lanthanum zirconium oxide (LLZO) powder (d 50 =0.4μm, specific surface area: 2.5m 2 / g) was added to a mixture of 140 g of polyethylene glycol 400 (PEG 400) and 50 ml of isopropanol. The particle suspension was mixed with 1030g ZrO 2 Grinding beads (d = 0.7-0.9 mm) were mixed and the batch was processed in a Netzsch PE 075S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com