System and method for reducing the amount of sulfur oxides in exhaust gas

A waste gas and waste gas pipe technology, which is applied in the direction of chemical instruments and methods, separation methods, combustion methods, etc., can solve the problems of size, weight, robustness, stability, etc., and can not be automatically interchanged, so as to reduce the speed of waste gas and simplify the installation space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

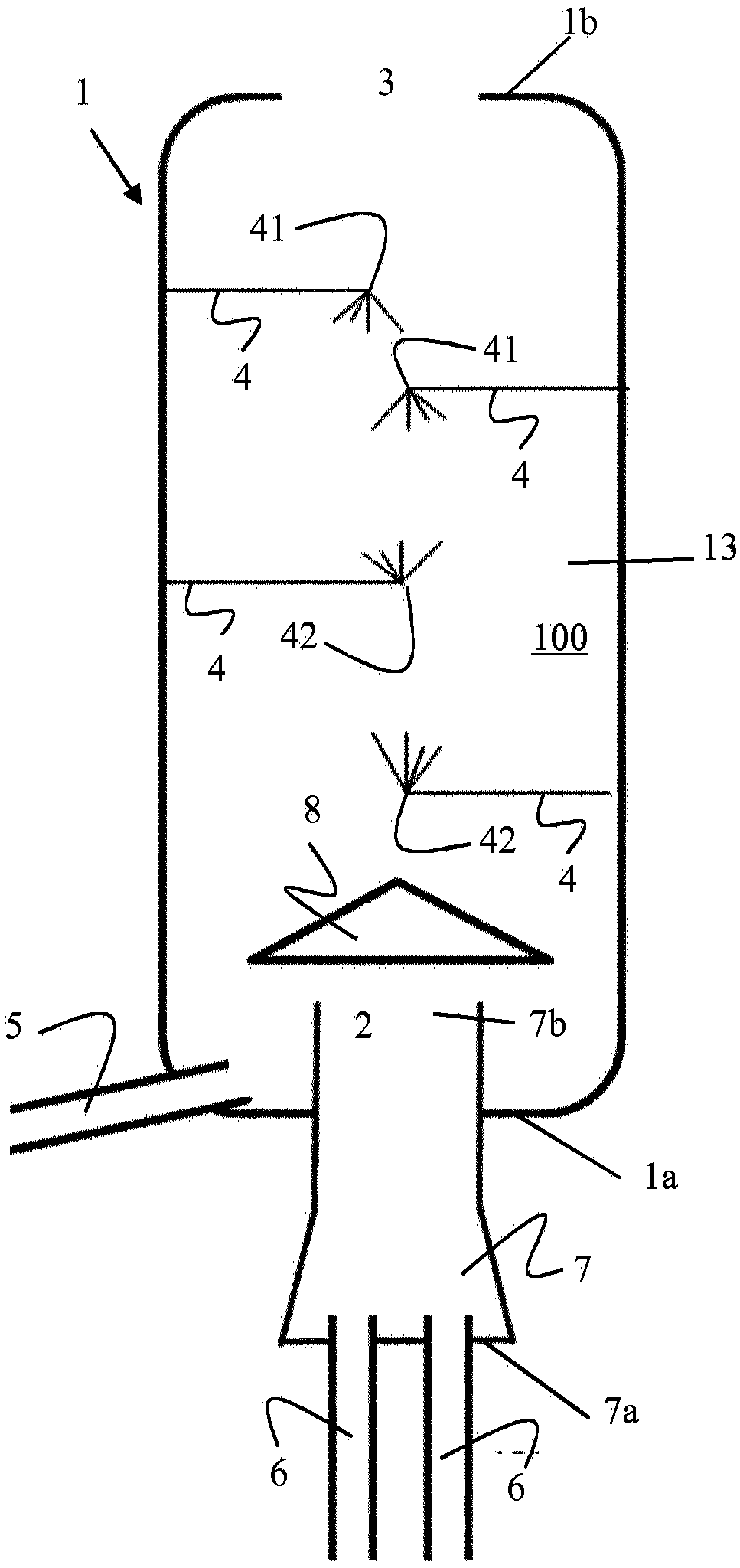

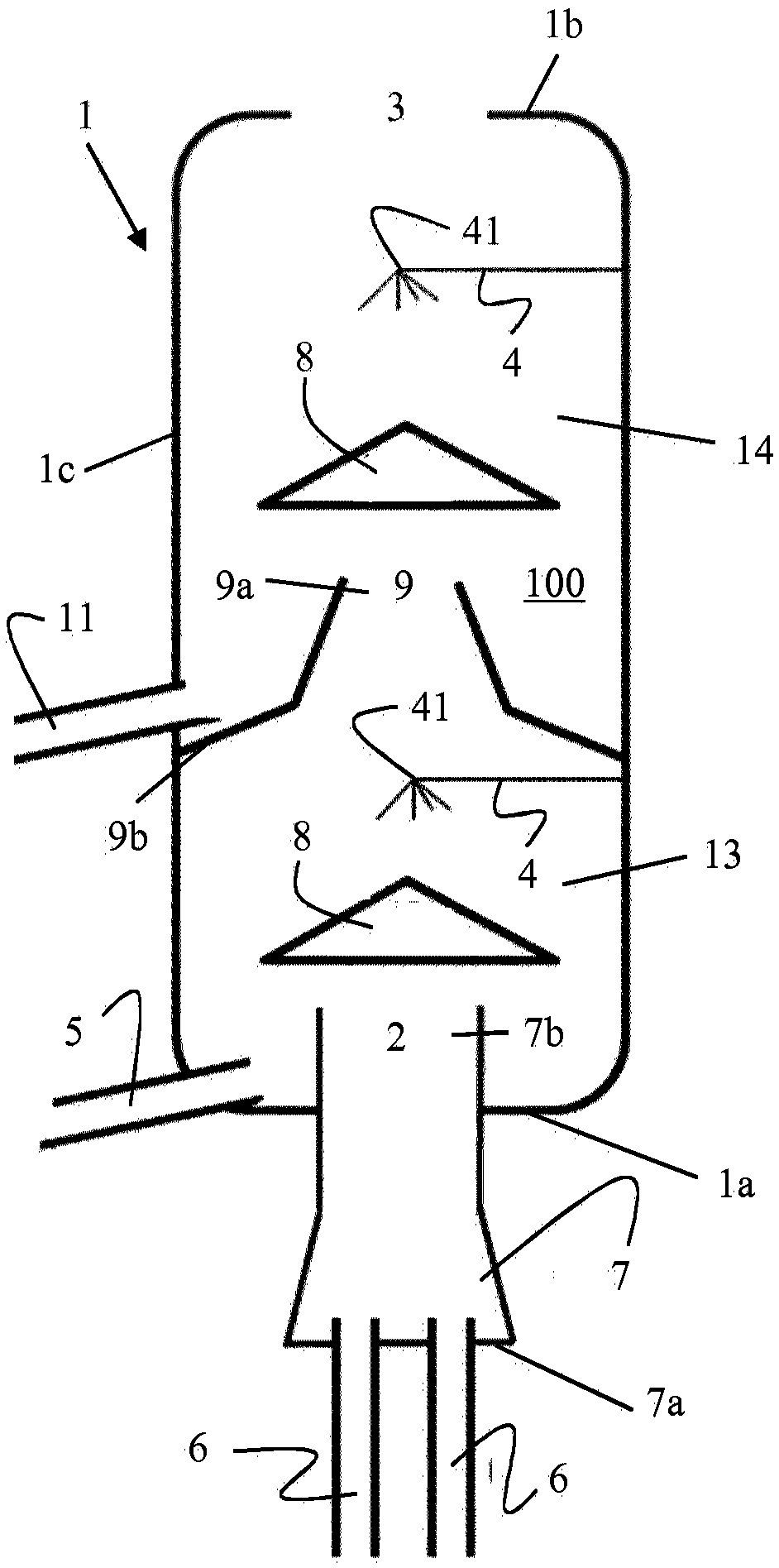

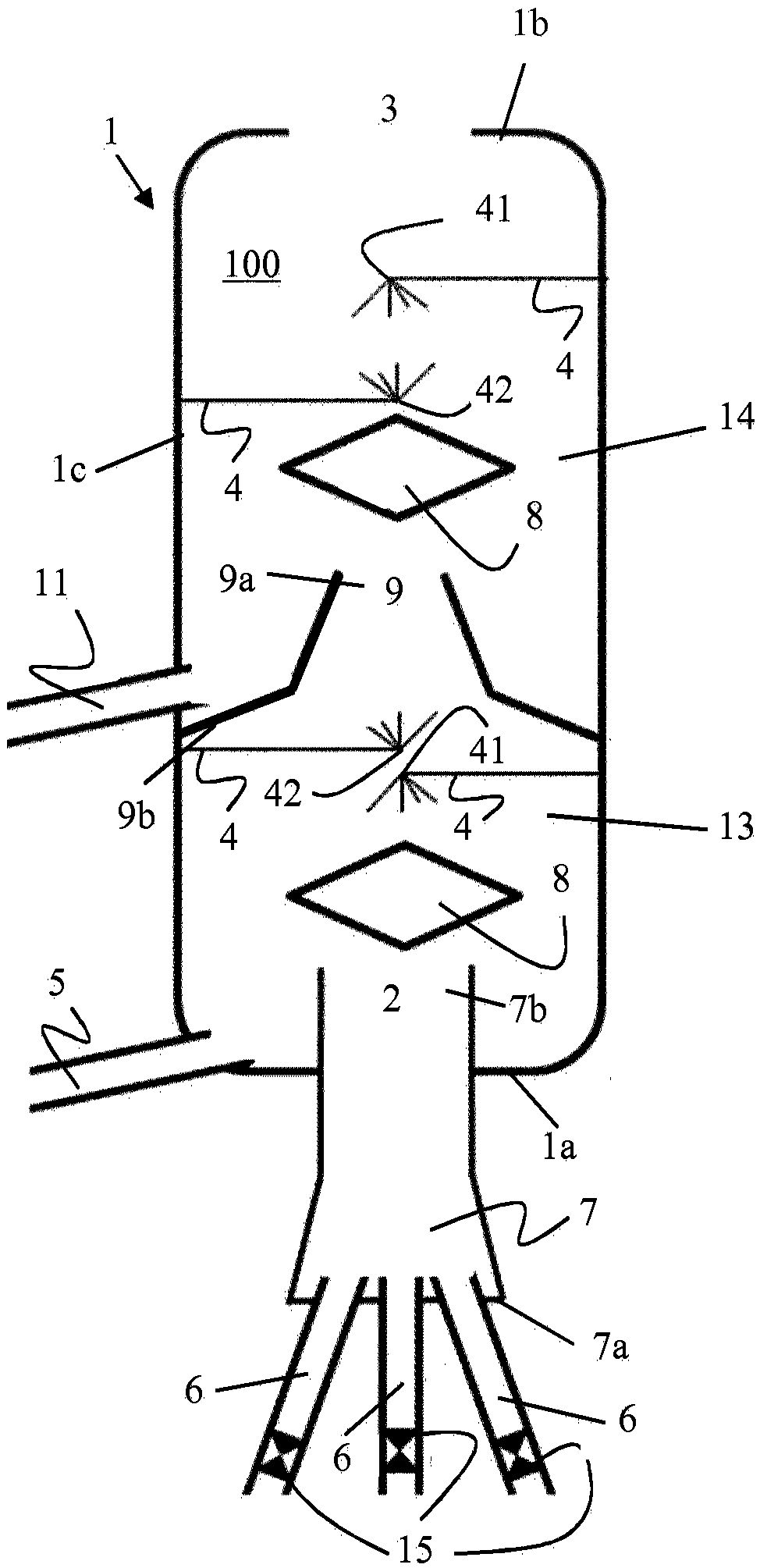

[0069] Such as Figures 1 to 5 As shown, various embodiments of the system according to the present application all include a method for removing SO from the exhaust gas produced by an engine (not shown in the figure), more specifically a marine engine. x The spray tower (1) is arranged to be placed substantially vertically. In its simplest form, the spray tower (1) consists of a cylinder with an inner space (100). In its installed state, the spray tower (1) also has a bottom end (1a) and a top end (1b). More particularly, the bottom end (1a) is located on the opposite side of the top end (1b) of the spray tower (1). More specifically, the cylinders have rotational symmetry about a common longitudinal axis. It is convenient to have the exhaust gas outlet (3) arranged coaxially through the upper end (1b) of the spray tower (1). The central waste gas pipe (7) is located at the bottom (1a) of the spray tower (1). The central exhaust gas tube (7) has an open proximal end (7b)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com