Alloy, lead-free solder material, preparation method and application thereof

A technology of lead-free solder and metal materials, applied in the direction of welding/cutting media/materials, welding equipment, metal processing equipment, etc., can solve the problems of glass parts cracking, glass breaking stress, etc., achieve good welding adhesion and reduce process The effect of requesting and guaranteeing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

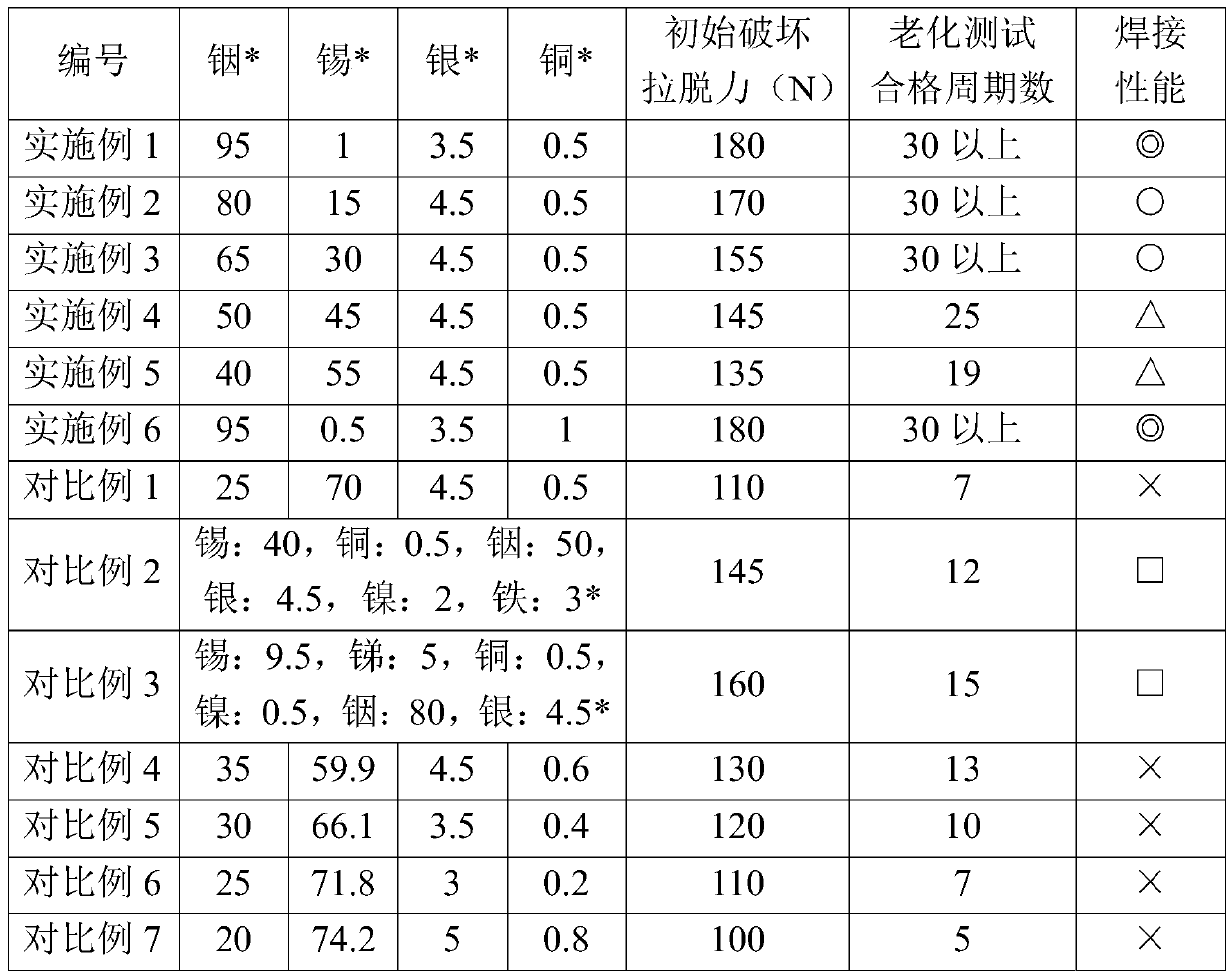

[0037] The present invention also provides a method for preparing a lead-free solder material, the method comprising: melting and molding a metal material to obtain a lead-free solder material, wherein the metal material includes 40-95% by weight of indium, 3-5% by weight silver, 0.2-1 wt% copper and 0.5-55 wt% tin, and unavoidable impurities.

[0038] Preferably, the metal material includes 60-95% by weight of indium, 3-5% by weight of silver, 0.2-1% by weight of copper, and 0.5-35% by weight of tin, as well as unavoidable impurities. More preferably, the metal material includes 60-80% by weight of indium, 3.5-4.5% by weight of silver, 0.4-0.6% by weight of copper, and 15-35% by weight of tin, as well as unavoidable impurities.

[0039] Preferably, the metal material includes 80-95% by weight of indium, 3.5-4.5% by weight of silver, 0.5-1% by weight of copper, and 0.5-15% by weight of tin, as well as unavoidable impurities. More preferably, the alloy of the metal material in...

preparation example

[0057] This preparation example is used to illustrate the preparation of solder wire.

[0058] (1) according to formula proportion shown in table 1, allocate metal material;

[0059] (2) Melt the metal material at 130°C for 0.5h and mix it. After mixing, use a multi-element analyzer to detect the ratio of each element. If the requirements are not met, you need to fine-tune the ratio by adding a small amount of metal material and melting and mixing again;

[0060] (3) casting the molten mixed metal material into a cylindrical shape with a diameter of 10mm under molten mixing conditions;

[0061] (4) Use a die-casting machine to perform die-casting at room temperature, and obtain materials with a diameter of 10mm-8mm-6mm in sequence through die-casting, and then use a wire drawing machine to draw a solder wire with a diameter of 5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com