Conjoined cross drill bit for drilling blast furnace molten iron outlet and production method of conjoined cross drill bit

A molten iron, cross-type technology, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as increased operating strength, low production efficiency, poor wear resistance and impact resistance, etc., to prolong service life and save Human and material resources, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

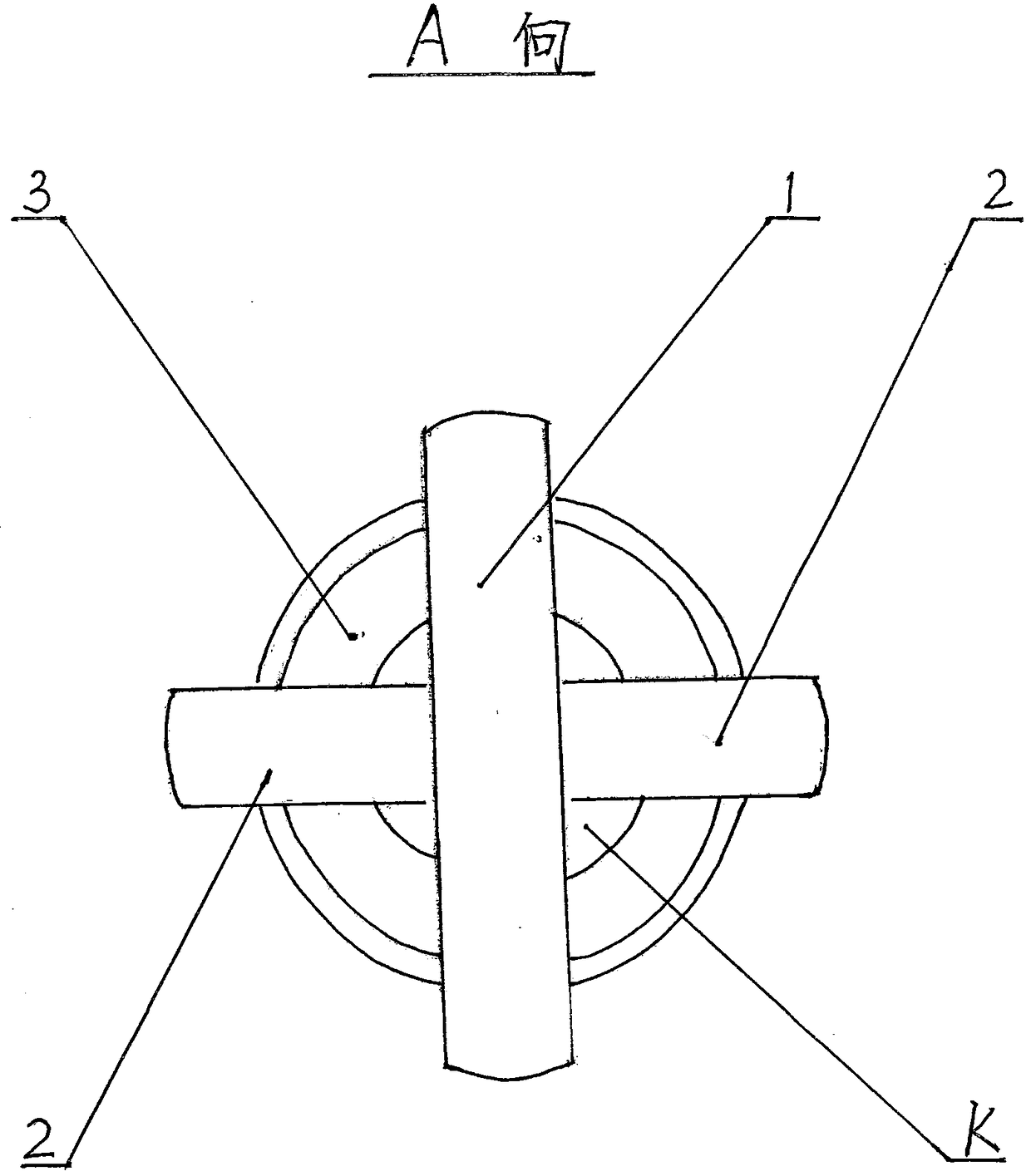

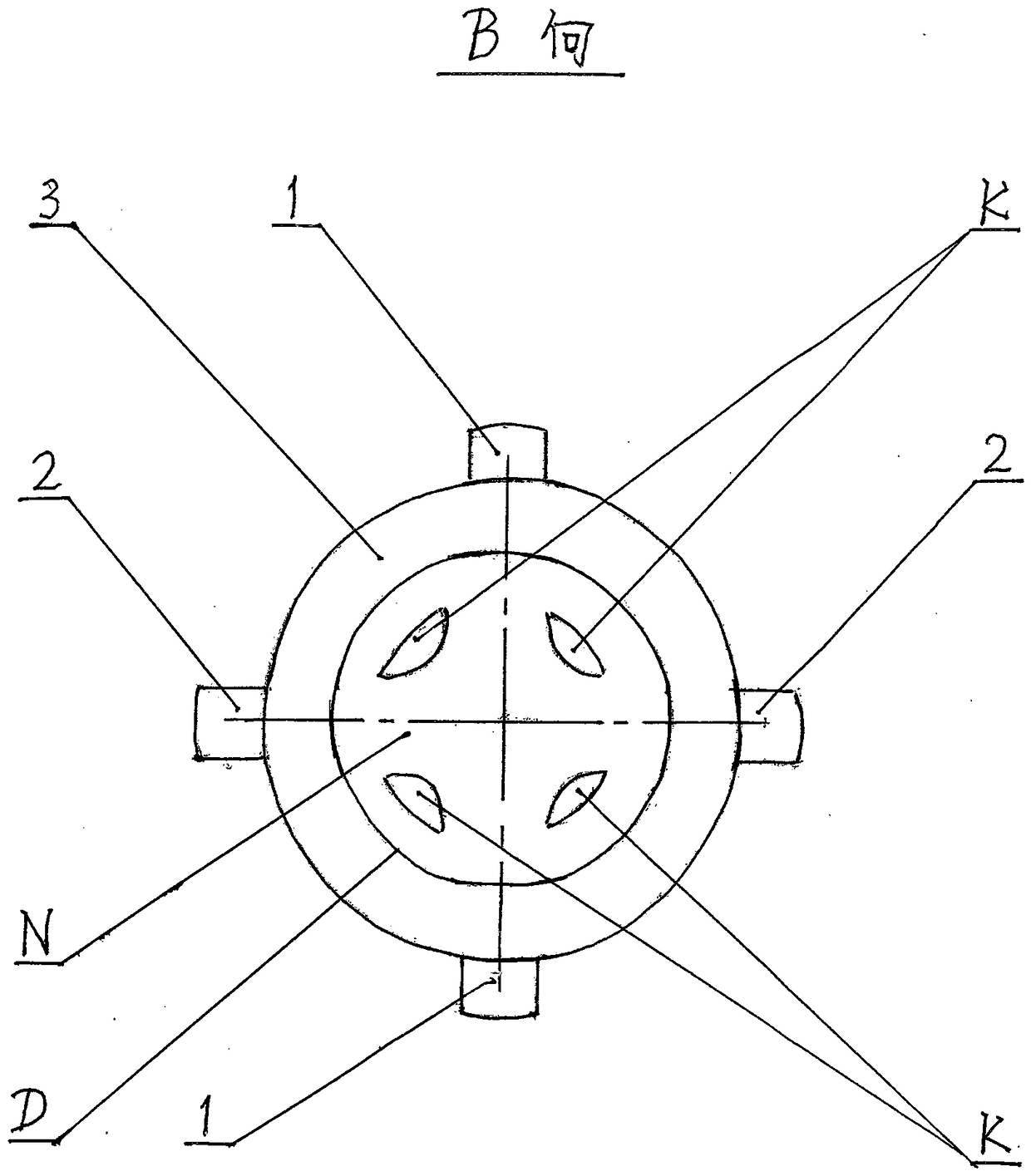

[0021] refer to figure 1 , figure 2 , image 3 , the conjoined cross-type drill bit of the present invention is composed of a longitudinal cutter head 1 and a transverse cutter head 2 in a 90-degree cross combination on a horizontal layer to form a cross-shaped drill bit top. The drill bit shank 3 is made of circular tubular metal, the top of the drill bit is connected and fixed with the drill bit shank 3 to form the whole drill bit, and the longitudinal cutter head 1 and the horizontal cutter head 2 are respectively sintered and infiltrated with a long hard alloy block 10 and a short hard alloy block 11. The outer edge of the top end of the center hole D of the drill shank 3 is welded to the outer ends of the longitudinal cutter head 1 and the transverse cutter head 2, and the inner cavity of the center hole D of the drill shank 3 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com