Double-crosslinking self-repairing epoxidized natural rubber and preparation method and application thereof

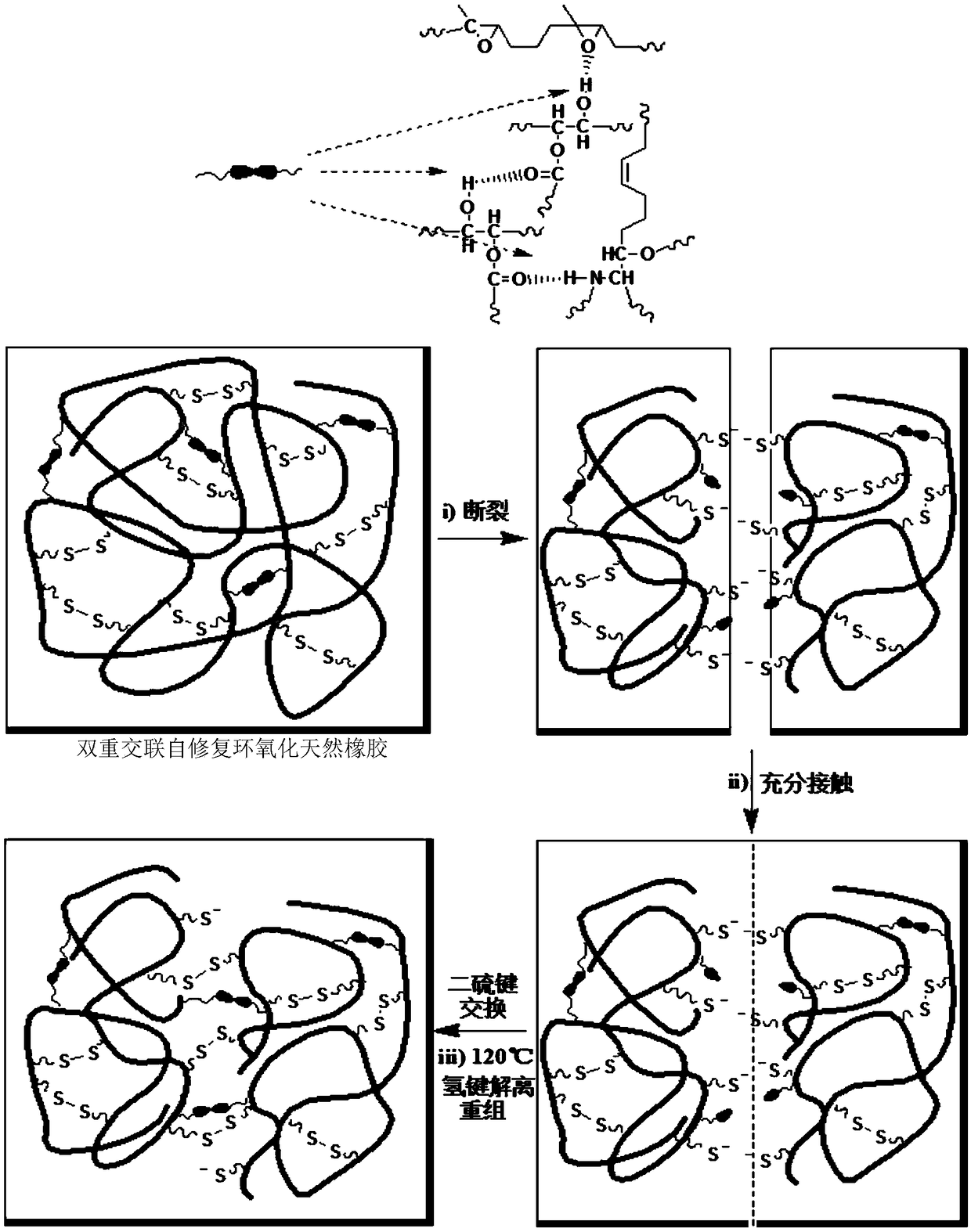

A natural rubber and double cross-linking technology, which is applied in the field of double cross-linking self-repairing epoxidized natural rubber and its preparation, can solve the problems of low mechanical properties, low cross-linking density, weak force, etc., and achieve high repair efficiency, The preparation process is simple to operate and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

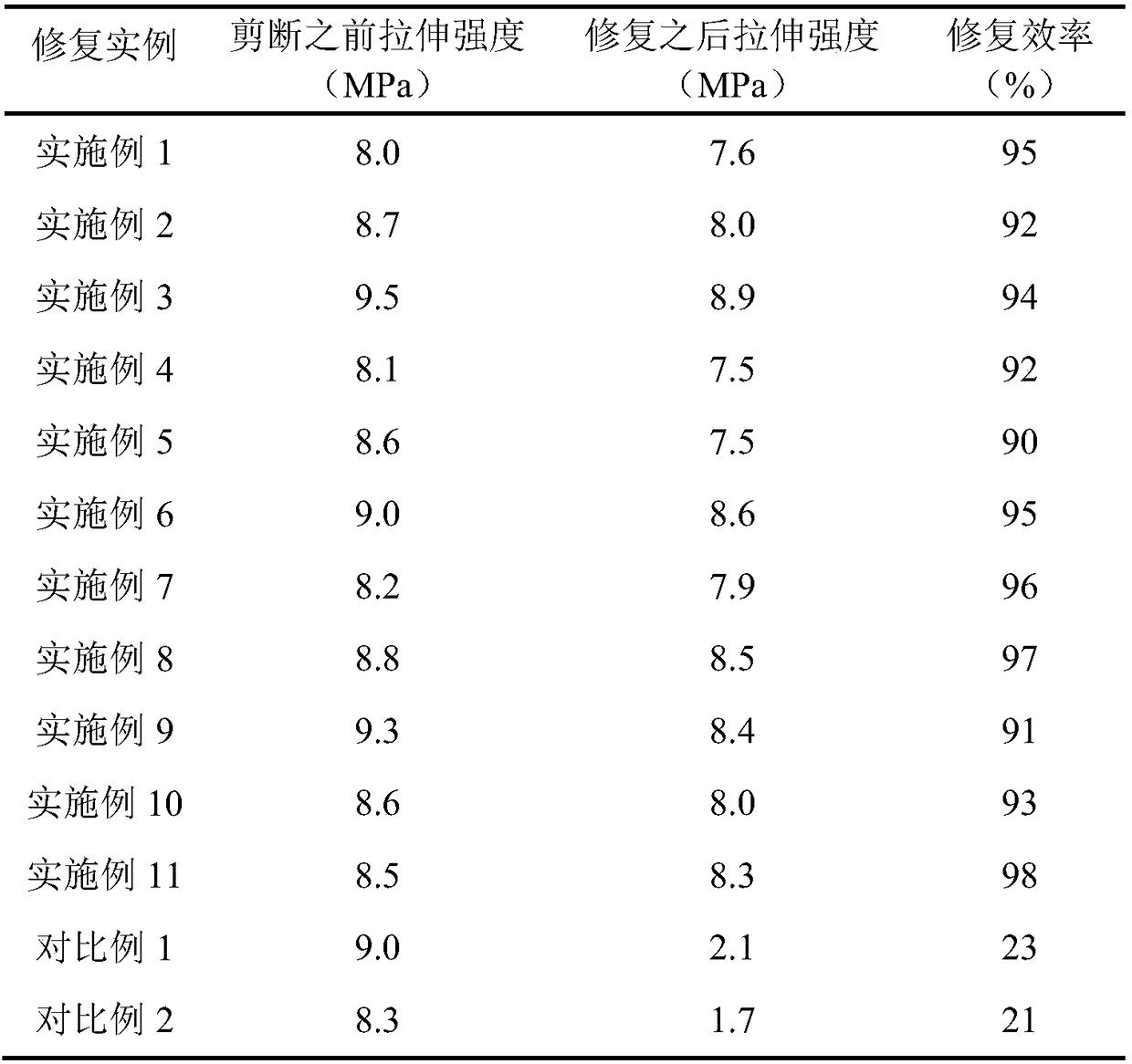

Embodiment 1

[0034] At 50°C, in parts by weight, masticate 100 parts of epoxidized natural rubber with an epoxidation degree of 25% on an open mill for 3 minutes, add 0.5 parts of basic magnesium carbonate and 3 parts of zinc oxide after wrapping , 3 parts of stearic acid, 0.5 parts of N-tert-butyl-2-benzothiazole sulfenamide, 1 part of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, phthalate Mix 10 parts of dioctyl formate, 1 part of sulfur, 1 part of 2,2′-dithiodibenzoic acid, and 1 part of 1,2-dimethylimidazole to make a mixed rubber; stand at room temperature for 8 hours Afterwards, at 155°C, pressure 100kgf / cm 2 vulcanized into a 2mm sheet to obtain double cross-linked self-healing epoxidized natural rubber. After standing at room temperature for 24 h, the mechanical properties of the material were measured by tensile test. After the material is cut as it is, the two sections are fully contacted, and after repairing at 120°C for 24 hours, the mechanical properties of the material are...

Embodiment 2

[0036] At 50°C, in parts by weight, masticate 100 parts of epoxidized natural rubber with an epoxidation degree of 40% on an open mill for 3 minutes, add 3 parts of basic magnesium carbonate and 3 parts of zinc oxide after wrapping , 1 part of stearic acid, 0.5 parts of N-tert-butyl-2-benzothiazole sulfenamide, 3 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, phthalate 8 parts of dioctyl formate, 1 part of sulfur, 2 parts of 3,3′-dithiodipropionic acid, and 2 parts of 1-methylimidazole were mixed evenly to obtain a mixed rubber; after standing at room temperature for 8 hours, the 155℃, pressure 100kgf / cm 2 vulcanized into a 2mm sheet to obtain double cross-linked self-healing epoxidized natural rubber. After standing at room temperature for 24 h, the mechanical properties of the material were measured by tensile test. After the material is cut as it is, the two sections are fully contacted, and after repairing at 110°C for 20 hours, the mechanical properties of the mat...

Embodiment 3

[0038] At 50°C, in parts by weight, masticate 100 parts of epoxidized natural rubber with an epoxidation degree of 50% on an open mill for 3 minutes, add 2 parts of basic magnesium carbonate and 5 parts of zinc oxide after wrapping , 2 parts of stearic acid, 2 parts of N-tert-butyl-2-benzothiazole sulfenamide, 3 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, phthalate Mix 5 parts of dioctyl formate, 1 part of sulfur, 3.2 parts of 4,4′-dithiodibutyric acid, and 2 parts of 1,2-dimethylimidazole to make a mixed rubber; let stand at room temperature for 8 hours Afterwards, at 155°C, pressure 100kgf / cm 2 vulcanized into a 2mm sheet to obtain double cross-linked self-healing epoxidized natural rubber. After standing at room temperature for 24 h, the mechanical properties of the material were measured by tensile test. After the material is cut as it is, the two sections are fully contacted, and after repairing at 120°C for 24 hours, the mechanical properties of the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com