Rare earth phosphate/bioactive polymer three-dimensional porous composite material, preparation method and application thereof

A rare earth phosphate, polymer material technology, applied in the fields of inorganic non-metallic materials, biomedical materials, organic bioactive polymer materials, can solve problems such as unclear effect, achieve favorable cell adhesion, high porosity, cycle time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) 2.9877g La(NO 3 ) 3 ·6H 2 O and 0.9112g (NH 4 ) 2 HPO 4 were dissolved in 100mL deionized water to prepare La(NO 3 ) 3 aqueous solution and (NH 4 ) 2 HPO 4 aqueous solution.

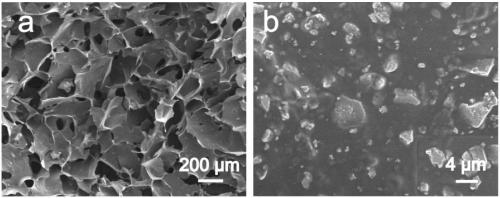

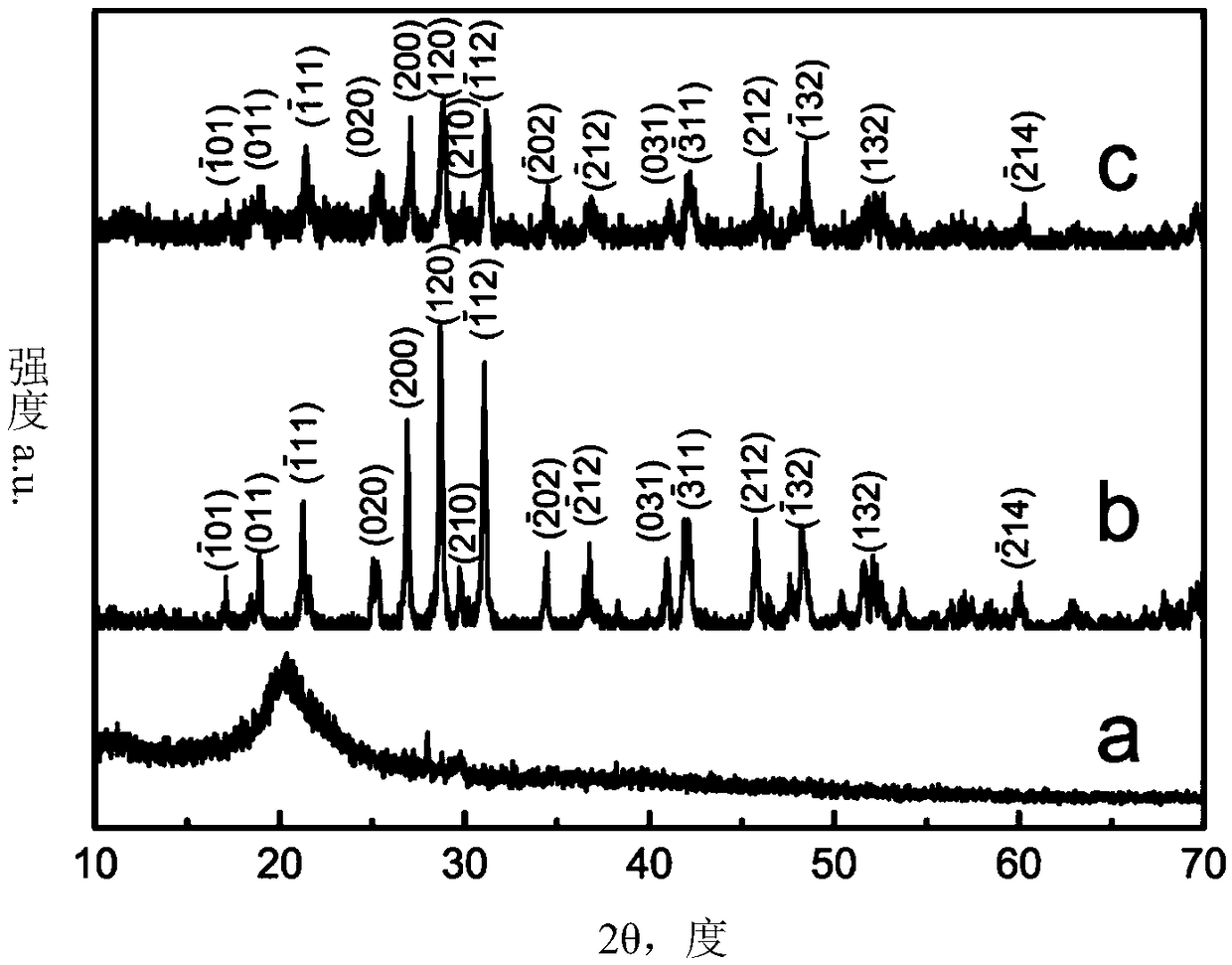

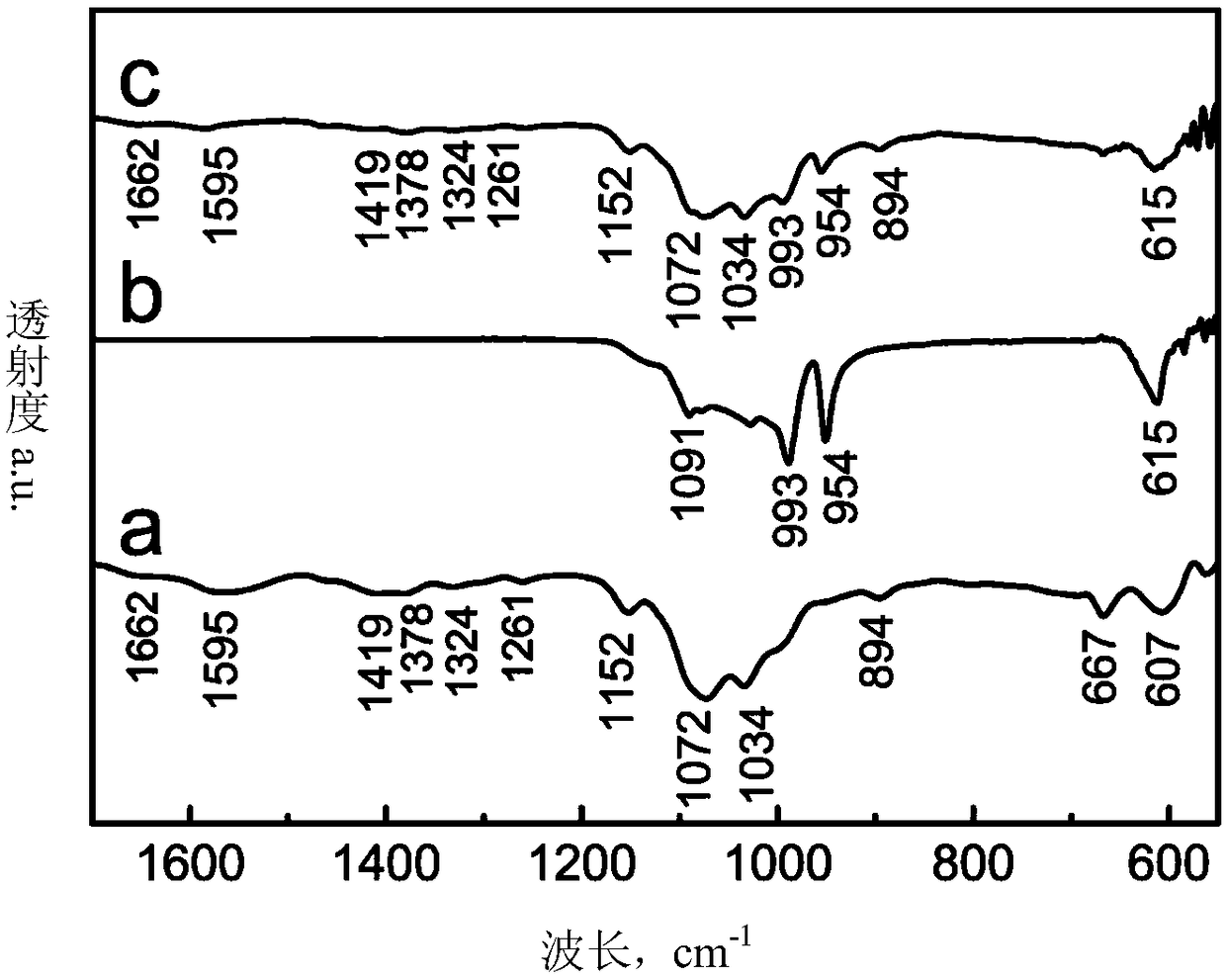

[0060] (2) to (NH 4 ) 2 HPO 4 Add NH to the aqueous solution 3 ·H 2 O adjust the pH to 11.5, then (NH 4 ) 2 HPO 4 The aqueous solution was placed in a 20°C oil bath for mechanical stirring while adding La(NO 3 ) 3 The aqueous solution, after the dropwise addition, was stirred at 90°C for 1 hour, then stirred at 20°C for 24 hours, filtered and washed to obtain a neutral precipitate, dried at 50°C for 12 hours, and calcined at 500°C for 6 hours to obtain lanthanum phosphate (LaPO 4 ) powder with a particle size of 50nm to 5μm.

[0061] (3) Take 100 mL of acetic acid solution with a volume fraction of 1%, add 4.0 g of chitosan, and stir to completely dissolve the chitosan until clear and transparent.

[0062] (4) Add 4.0 g of lanthanum phosphate powder into the chitosan solut...

Embodiment 2

[0072] (1) 2.9877g La(NO 3 ) 3 ·6H 2O and 0.9112g (NH 4 ) 2 HPO 4 were dissolved in 100mL deionized water to prepare La(NO 3 ) 3 aqueous solution and (NH 4 ) 2 HPO 4 aqueous solution.

[0073] (2) to (NH 4 ) 2 HPO 4 Add NH to the aqueous solution 3 ·H 2 O to adjust the pH to 11, the (NH 4 ) 2 HPO 4 The aqueous solution was placed in a 20°C oil bath for mechanical stirring while adding La(NO 3 ) 3 The aqueous solution, after the dropwise addition, was stirred at 70°C for 1 hour, then stirred at 20°C for 24 hours, filtered and washed to obtain a neutral precipitate, dried at 90°C for 5 hours, and calcined at 1000°C for 6 hours to obtain lanthanum phosphate (LaPO 4 ) powder with a particle size of 50nm to 5μm.

[0074] (3) Take 100 mL of acetic acid solution with a volume fraction of 4%, add 2.0 g of collagen, and stir to completely dissolve the collagen until clear and transparent.

[0075] (4) Add 4.0 g of lanthanum phosphate powder into the collagen soluti...

Embodiment 3

[0082] (1) 2.9961g Ce(NO 3 ) 3 ·6H 2 O and 0.9112g (NH 4 ) 2 HPO 4 were dissolved in 100mL deionized water to prepare Ce(NO 3 ) 3 aqueous solution and (NH 4 ) 2 HPO 4 aqueous solution.

[0083] (2) to (NH 4 ) 2 HPO 4 Add NH to the aqueous solution 3 ·H 2 O to adjust the pH to 11, the (NH 4 ) 2 HPO 4 The aqueous solution was placed in an oil bath at 40°C for mechanical stirring while adding Ce(NO 3 ) 3 The aqueous solution, after the dropwise addition, was stirred at 90°C for 2 hours, then stirred at 40°C for 24 hours, filtered and washed to obtain a neutral precipitate, dried at 90°C for 5 hours, and calcined at 1000°C for 3 hours to obtain cerium phosphate (CePO 4 ) powder with a particle size of 50nm to 5μm.

[0084] (3) Take 100 mL of hydrochloric acid solution with a volume fraction of 0.5%, add 4.0 g of collagen, and keep stirring to completely dissolve the collagen until clear and transparent.

[0085] (4) Add 2.0 g of cerium phosphate powder into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com