Coloration process of brass zipper

A zipper and brass technology, applied in the coating process of metal materials, etc., can solve the problems of poor color fastness to washing and corrosion resistance, unfavorable large-scale application, light color of the color film layer, etc., and achieve the coloring process Simple and easy to implement, high promotion and application value, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

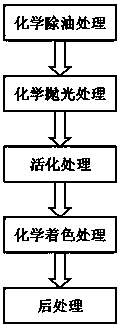

Image

Examples

Embodiment 1

[0020] The specific processing method is as follows:

[0021] a) Chemical degreasing treatment, first, according to the mass concentration, mix 50g / L sodium hydroxide, 50g / L sodium phosphate, 20g / L sodium carbonate, 8g / L anhydrous sodium sulfate, and prepare the degreasing Oil solution; then fully wash the brass zipper with deionized water, then immerse the brass zipper in degreasing solution, degrease at 60°C for 5 minutes; finally wash in hot water at 70°C for 5 minutes.

[0022] b) Chemical polishing treatment, firstly mix 650mL / L hydrogen peroxide, 30g / L sulfuric acid, 140g / L ethylene glycol, 2g / L OP-10 emulsifier according to the volume concentration and mass concentration, Prepare a polishing solution; then immerse the degreasing brass zipper in the polishing solution, and polish it at 20°C for 2 minutes.

[0023] c) Activation treatment, first fully wash the polished brass zipper with deionized water, then activate it with 10% sulfuric acid solution at 25°C for 20s, an...

Embodiment 2

[0027] The specific processing method is as follows:

[0028] a) Chemical degreasing treatment, first, according to the mass concentration, mix 50g / L sodium hydroxide, 50g / L sodium phosphate, 20g / L sodium carbonate, 8g / L anhydrous sodium sulfate, and prepare the degreasing Oil solution; then fully wash the brass zipper with deionized water, then immerse the brass zipper in degreasing solution, degrease at 65°C for 4 minutes; finally wash with hot water at 75°C for 4 minutes.

[0029] b) Chemical polishing treatment, firstly mix 650mL / L hydrogen peroxide, 30g / L sulfuric acid, 140g / L ethylene glycol, 2g / L OP-10 emulsifier according to the volume concentration and mass concentration, Prepare a polishing solution; then immerse the degreased brass zipper in the polishing solution, and polish it at 25°C for 1.5 minutes.

[0030] c) Activation treatment, first fully wash the polished brass zipper with deionized water, then activate it with 10% sulfuric acid solution at 25°C for 20s,...

Embodiment 3

[0034] The specific processing method is as follows:

[0035] a) Chemical degreasing treatment, first, according to the mass concentration, mix 50g / L sodium hydroxide, 50g / L sodium phosphate, 20g / L sodium carbonate, 8g / L anhydrous sodium sulfate, and prepare the degreasing Oil solution; then fully wash the brass zipper with deionized water, then immerse the brass zipper in degreasing solution, degrease at 70°C for 3 minutes; finally wash in hot water at 80°C for 3 minutes.

[0036] b) Chemical polishing treatment, firstly mix 650mL / L hydrogen peroxide, 30g / L sulfuric acid, 140g / L ethylene glycol, 2g / L OP-10 emulsifier according to the volume concentration and mass concentration, Prepare a polishing solution; then immerse the degreased brass zipper in the polishing solution, and polish it at 30°C for 1 min.

[0037] c) Activation treatment, first fully wash the polished brass zipper with deionized water, then activate it with 10% sulfuric acid solution at 25°C for 20s, and fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com