Preparation method for acrylate finish-coat paint emulsion

A technology of acrylate and butyl acrylate, which is applied in the field of preparation of acrylate finish paint emulsion, can solve the problems of poor waterproof performance of finish paint, little improvement of surface gloss, and insufficient film density, etc., achieving excellent Water resistance, increased nucleation rate, and small product particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add 3.1 parts of sodium lauryl sulfate and 100 parts of deionized water into a four-neck flask, stir evenly at a speed of 160 r / min, and raise the temperature to 82°C.

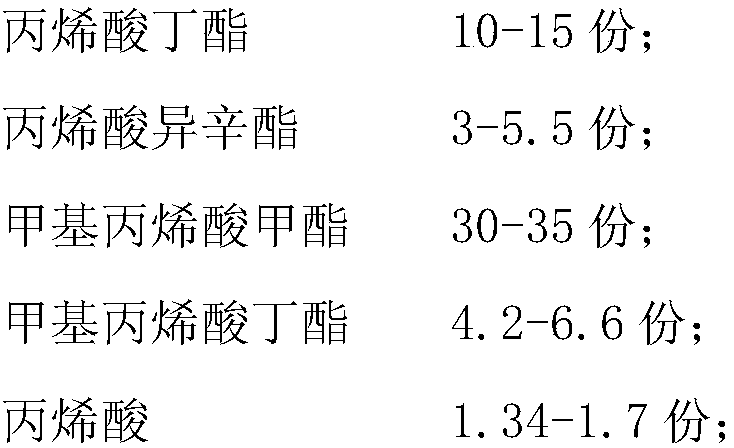

[0041] 10 parts of butyl acrylate, 4.2 parts of isooctyl acrylate, 33.2 parts of methyl methacrylate, 5.9 parts of butyl methacrylate, 1.7 parts of acrylic acid and 1.67 parts of isoamyl alcohol were mixed. The dropwise addition of the monomer / cosurfactant mixture was started, during which time 0.33 parts of ammonium persulfate was evenly added to the reaction system. Reduce the rotational speed to 140r / min, and control the dropping time at 2h.

[0042] After the dropwise addition, raise the temperature to 90°C, reduce the stirring speed to 100r / min and keep it warm for 50min to complete the reaction of the monomer, filter it with a filter cloth, and discharge the material to obtain an acrylic finish paint emulsion.

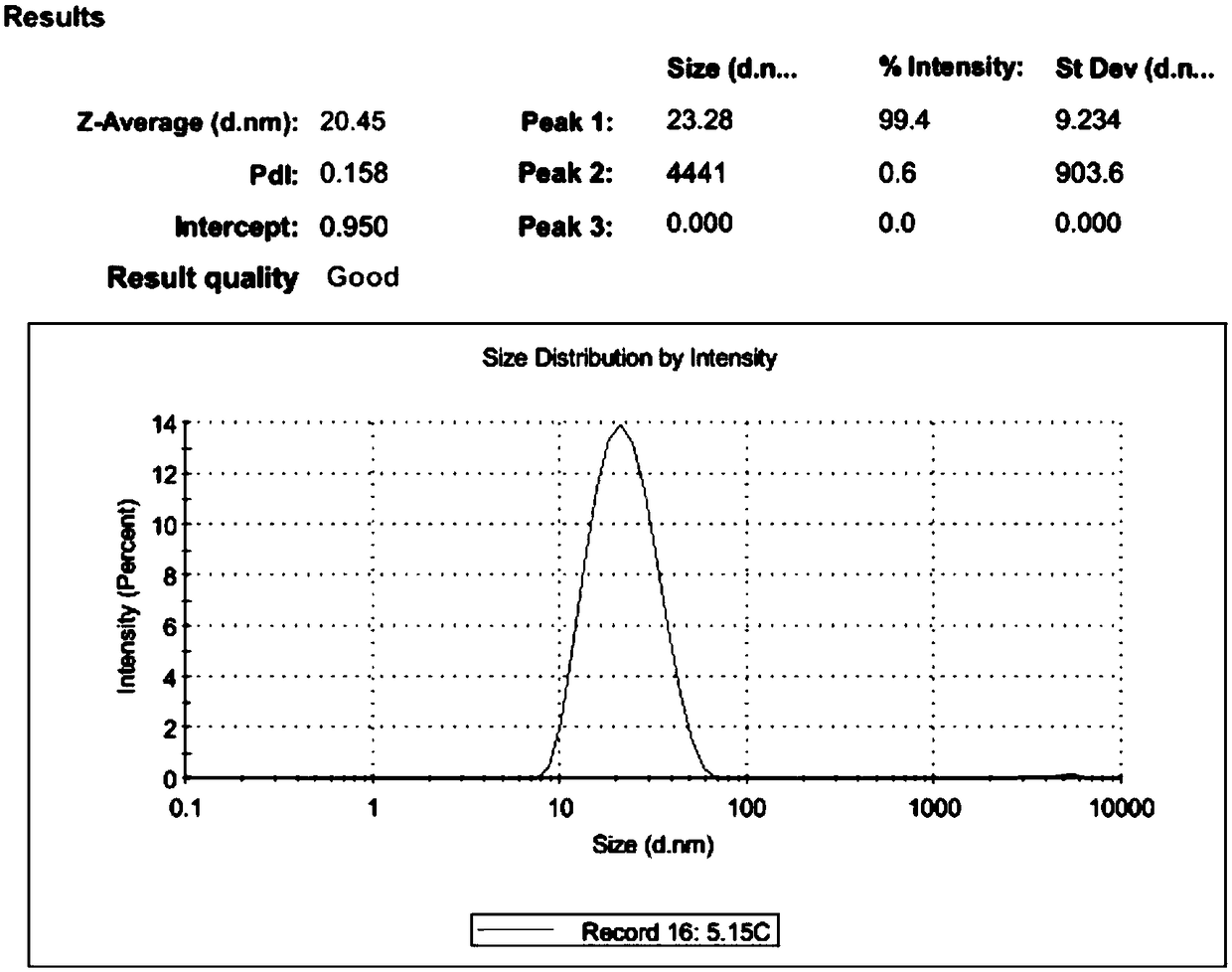

[0043] The resulting emulsion particle size test see figure 1 , indicating a particl...

Embodiment 2

[0045] Add 1.5 parts of sodium lauryl sulfate, 0.6 parts of sodium alkylphenol polyoxyethylene ether sulfate and 110 parts of deionized water into a four-necked flask, stir evenly at a speed of 160 r / min, and raise the temperature to 82 °C.

[0046] 12.4 parts of butyl acrylate, 3.5 parts of isooctyl acrylate, 30 parts of methyl methacrylate, 6.6 parts of butyl methacrylate, 1.55 parts of acrylic acid and 1.78 parts of n-amyl alcohol were mixed. The dropwise addition of the monomer / cosurfactant mixture was started, during which 0.29 parts of potassium persulfate was uniformly added to the reaction system. Reduce the rotational speed to 140r / min, and control the dropping time at 2.5h.

[0047] After the dropwise addition, raise the temperature to 90°C, reduce the stirring speed to 100r / min and keep it warm for 50min to complete the monomer reaction, filter with filter cloth, and discharge to obtain the acrylic finish paint emulsion.

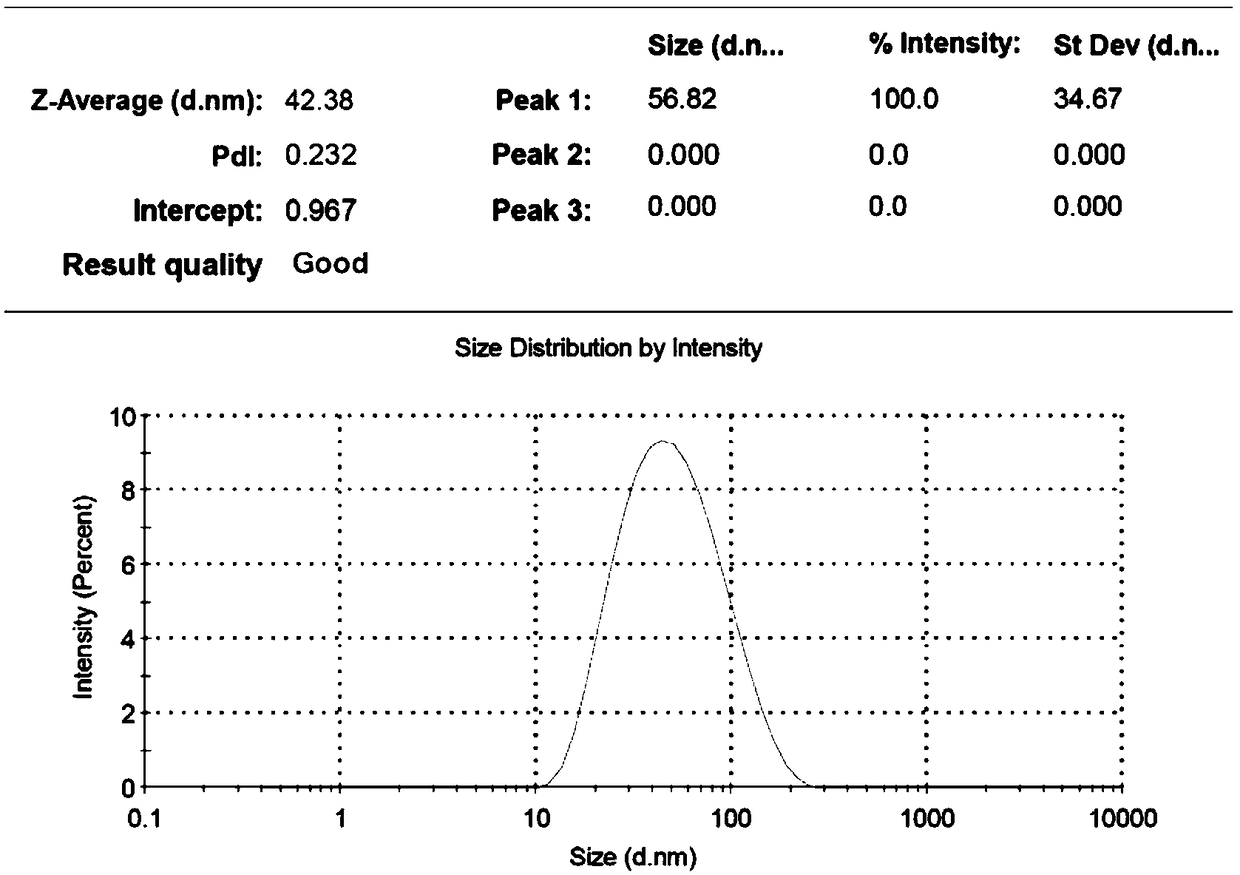

[0048] The resulting emulsion particle siz...

Embodiment 3

[0050] Add 1.8 parts of sodium dodecyl sulfate, 0.7 parts of sodium dodecylbenzenesulfonate and 90 parts of deionized water into a four-neck flask, stir evenly at a high speed of 160 r / min, and raise the temperature to 82°C.

[0051]13.4 parts of butyl acrylate, 3 parts of isooctyl acrylate, 33 parts of methyl methacrylate, 4.9 parts of butyl methacrylate, 1.34 parts of acrylic acid were mixed with 0.86 parts of isoamyl alcohol, 0.86 parts of n-amyl alcohol. The dropwise addition of the monomer / cosurfactant mixture was started, during which time 0.27 parts of ammonium persulfate was evenly added to the reaction system. Reduce the rotational speed to 140r / min, and control the dropping time at 2.5h.

[0052] After the dropwise addition, raise the temperature to 90°C, reduce the stirring speed to 100r / min and keep it warm for 50min to complete the monomer reaction, filter with a filter cloth, and discharge to obtain the acrylic finish paint emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com