A method for preparing high-quality thick film AlN based on a nano-pattern silicon substrate

A nano-patterning and substrate technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of increasing the growth cycle and increasing the cost of epitaxy, so as to improve the thickness of epitaxy, improve crystal quality and device performance, reduce Effect of defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

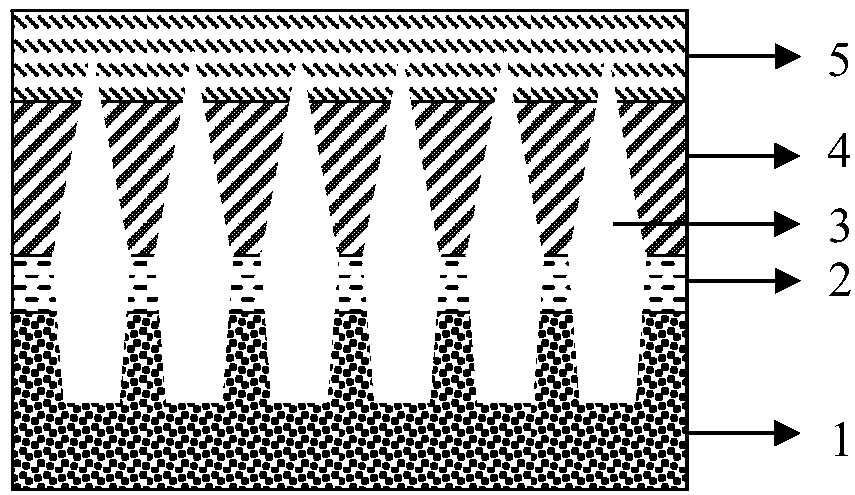

[0048] For the preparation process of high-quality thick-film AlN materials on nano-patterned Si substrates, see figure 2 , including the following steps:

[0049] (1) Select a single crystal silicon substrate 1, and the crystal orientation of silicon can be silicon (111), silicon (100), silicon (110), etc.;

[0050] (2) Growing an aluminum nitride nucleation layer 2 on a single crystal silicon substrate 1, the growth temperature is 900-1300° C., the growth pressure is 10-200 mbar, and the growth thickness is 10 nm, such as figure 2 as shown in (a);

[0051] (3) A layer of hard mask silicon dioxide 6 is deposited on the aluminum nitride nucleation layer 2 by plasma enhanced chemical vapor deposition (PECVD), the deposition temperature is 200-400 ° C, and the growth thickness is 10 nm-2 μm, like figure 2 as shown in (b);

[0052] (4) Select the structure and size of the nanoimprint template, use a hexagonal hole array, the pattern period is 1 μm, the pattern aperture is 600...

Embodiment 2

[0065] Methods for preparing high-quality thick-film AlN materials on nanopatterned Si substrates see figure 2 , including the following steps:

[0066] (1) Select a single crystal silicon substrate 1, the crystal orientation of silicon can be silicon (111), silicon (100);

[0067] (2) growing the aluminum nitride nucleation layer 2 on the single crystal silicon substrate 1, the growth temperature is 900-1300°C, the growth pressure is 10-200mbar, and the growth thickness is 200nm;

[0068] (3) deposit a layer of hard mask silicon dioxide on the aluminum nitride nucleation layer 2 by plasma enhanced chemical vapor deposition (PECVD), the deposition temperature is 200-400 ° C, and the growth thickness is 10 nm-2 μm;

[0069] (4) Select the structure and size of the nanoimprint template, use a hexagonal hole array, the pattern period is 1.4 μm, the pattern aperture is 1 μm, and the pattern depth is 500 nm;

[0070] (5) spin-coating nano-imprinting adhesive with a specific thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Etching depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Corrosion time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com