A method for prolonging the life of CT tube

A tube and service life technology, which is applied in the field of prolonging the life of the tube and extending the life of the CT tube, can solve the problems of the insignificant increase in the life of the CT tube, the increase in the cost of CT equipment, and the low life of the CT tube, achieving small brittleness , less stress, longer life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for prolonging the life of CT bulbs can be achieved through the following specific process steps:

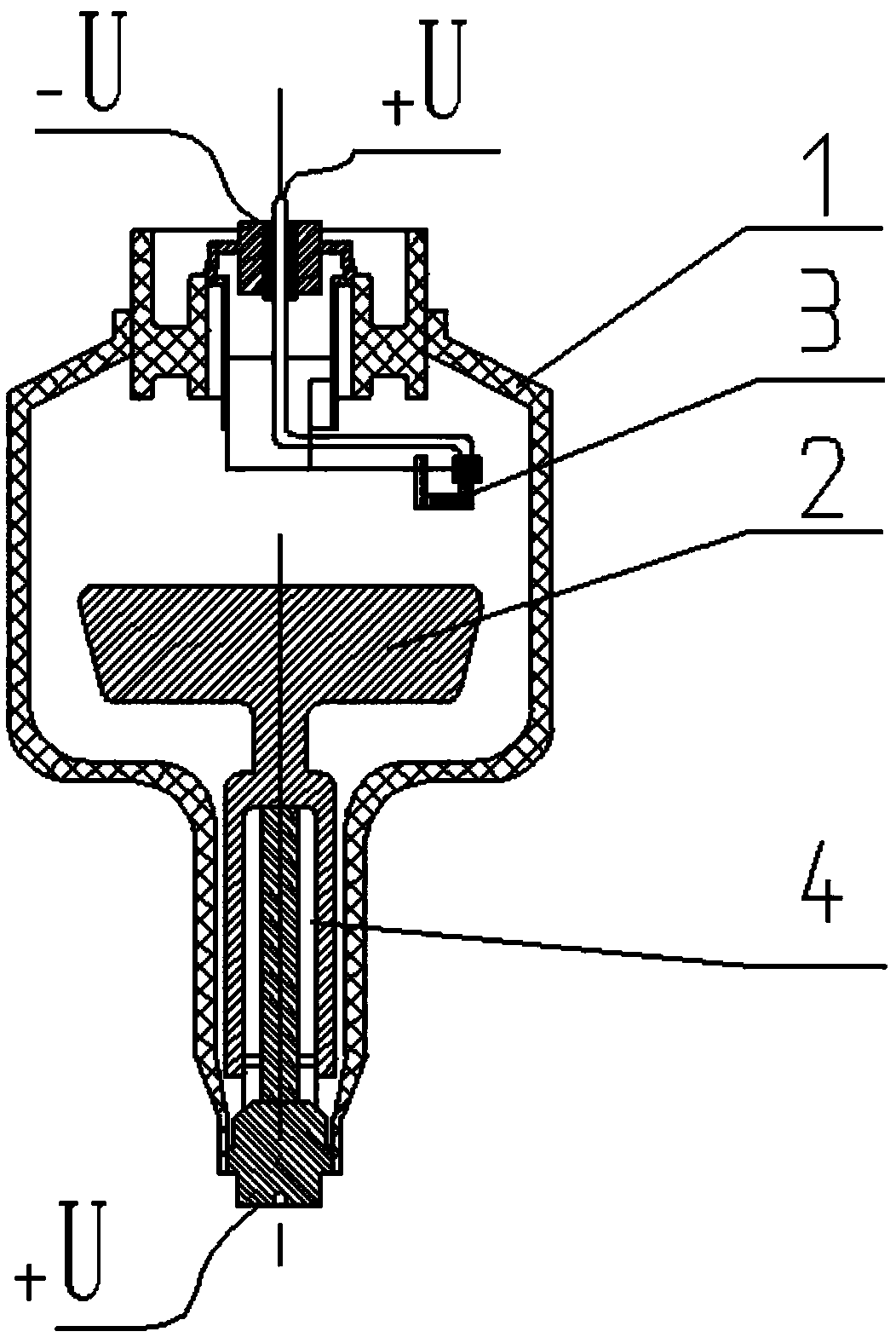

[0024] ①The CT tube of the present invention mainly includes a tube shell (1), a rotating anode target (2) connected to the tube shell (1) and a rotating anode target (2) located in the tube shell (1) ) corresponding to the cathode (3); wherein, the rotating anode target (2) is connected to the shell (1) through the bearing (4);

[0025] 2. The composition and mass fraction thereof of the shell (1) described in the step 1. are: 42% SiO 2 , 3.5% MgO, 8% CaO, 9.6% Al 2 o 3 , 0.5% B 2 o 3 , 3.2% TiO 2 , 1.2% CeO 2 , 0.3% ZnO 2 , 3% sodium silicate, 10% soda ash, 2.5% dimethylol urea, 4% sodium nitrate, 6% calcite, 0.5% K 2 O and 1.5% Na 2 O, and 2.2%≥K 2 O+Na 2 O≥1.9%, 2.2% niobium pentoxide, 0.4% antimony trioxide, 1.6% Bi(NO 3 )3. The sum of the mass fractions of the above raw materials is 100%. After the above raw materials are fully mixed, they are m...

Embodiment 2

[0028] A method for prolonging the life of CT bulbs can be achieved through the following specific process steps:

[0029] ①The CT tube of the present invention mainly includes a tube shell (1), a rotating anode target (2) connected to the tube shell (1) and a rotating anode target (2) located in the tube shell (1) ) corresponding to the cathode (3); wherein, the rotating anode target (2) is connected to the shell (1) through the bearing (4);

[0030] 2. The composition and mass fraction thereof of the tube shell (1) described in step 1. are: 42.4% SiO 2 , 4.5% MgO, 6% CaO, 10% Al 2 o 3 , 0.8% B 2 o 3 , 3.0% TiO 2 , 1.5% CeO 2 , 0.2% ZnO 2 , 4% sodium silicate, 8% soda ash, 3.0% dimethylol urea, 3% sodium nitrate, 7% calcite, 0.8% K 2 O and 1.2% Na 2 O, and 2.2%≥K 2 O+Na 2 O≥1.9%, 2.5% niobium pentoxide, 0.3% antimony trioxide, 1.8% Bi(NO 3 )3. The sum of the mass fractions of the above-mentioned raw materials is 100%; after the above-mentioned raw materials are fu...

Embodiment 3

[0033] A method for prolonging the life of CT bulbs can be achieved through the following specific process steps:

[0034] ①The CT tube of the present invention mainly includes a tube shell (1), a rotating anode target (2) connected to the tube shell (1) and a rotating anode target (2) located in the tube shell (1) ) corresponding to the cathode (3); wherein, the rotating anode target (2) is connected to the shell (1) through the bearing (4);

[0035] 2. The composition and mass fraction thereof of the shell (1) described in the step 1. are: 44.9% SiO 2 , 4% MgO, 6% CaO, 9% Al 2 o 3 , 0.6% B 2 o 3 , 3.1% TiO 2 , 1.4% CeO 2 , 0.3% ZnO 2 , 3.5% sodium silicate, 8% soda ash, 2.8% dimethylol urea, 3.5% sodium nitrate, 6.5% calcite, 0.6% K 2 O and 1.3% Na 2 O, and 2.2%≥K 2 O+Na 2 O≥1.9%, 2.4% niobium pentoxide, 0.4% antimony trioxide, 1.7% Bi(NO 3 )3, the sum of the mass fractions of the above-mentioned raw materials is 100%; after the above-mentioned raw materials are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com