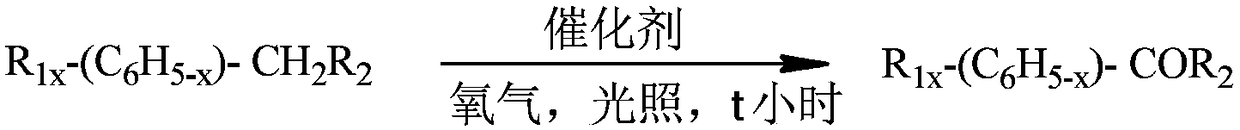

Method for photocatalytic oxidation of hydrocarbons

A technology for catalyzing hydrocarbons and photocatalysis, which is applied in chemical instruments and methods, oxidation preparation of carbonyl compounds, physical/chemical process catalysts, etc., can solve the problem of difficult and easy control of product selectivity, and achieve mild conditions, high selectivity, high The effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] In a 10mL pressure-resistant reaction tube, add 20mg N-doped TiO 2 (N content: 1wt%), 1mmol toluene, 5mL acetonitrile as solvent, 1atm oxygen, under stirring conditions at room temperature, irradiated by LED lamp for 12 hours, the light intensity is 20mW / cm –2 After the reaction, the GC-MS detection conversion rate was 48%, and the benzaldehyde selectivity was >99%. The catalyst was filtered off, the solvent was removed by rotary evaporation, petroleum ether and ethyl acetate (volume ratio 10:1) column separation, and the separation yield of benzaldehyde could reach 40%.

Embodiment 2

[0014] In a 10mL pressure-resistant reaction tube, add 20mg N-doped TiO 2 (N content: 2wt%), 1mmol ethylbenzene, 5mL acetonitrile as a solvent, 1atm oxygen, under room temperature stirring conditions, LED light irradiation for 12 hours, the light intensity is 20mW / cm –2 , after the reaction finished, the GC-MS detection conversion rate was 80%, and the acetophenone selectivity was >99%, and the catalyst was filtered off, and by rotary evaporation, the solvent was removed, sherwood oil and ethyl acetate (volume ratio 10:1) column Separation, the separation yield of acetophenone can reach 70%.

Embodiment 3

[0016] In a 10mL pressure-resistant reaction tube, add 20mg N-doped TiO 2 (N content: 5wt%), 1mmol cyclohexane, 5mL acetonitrile as a solvent, 1atm oxygen, under room temperature stirring conditions, LED light irradiation for 12 hours, the light intensity is 20mW / cm –2 , after the reaction finished, the GC-MS detection conversion rate was 28%, and the cyclohexanone selectivity was >99%, and the catalyst was filtered off, and by rotary evaporation, the solvent was removed, sherwood oil and ethyl acetate (volume ratio 10:1) column Separation, the separation yield of cyclohexanone can reach 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com