A kind of brake friction lining material with high stable friction coefficient and preparation method thereof

A technology of friction coefficient and friction plate, which is applied in the field of brake friction plate materials with high and stable friction coefficient and its preparation, can solve the problems of low wear resistance, easy wear of brake pads, low impact strength, etc., and achieve service life The effect of long, stable friction coefficient and high pressing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

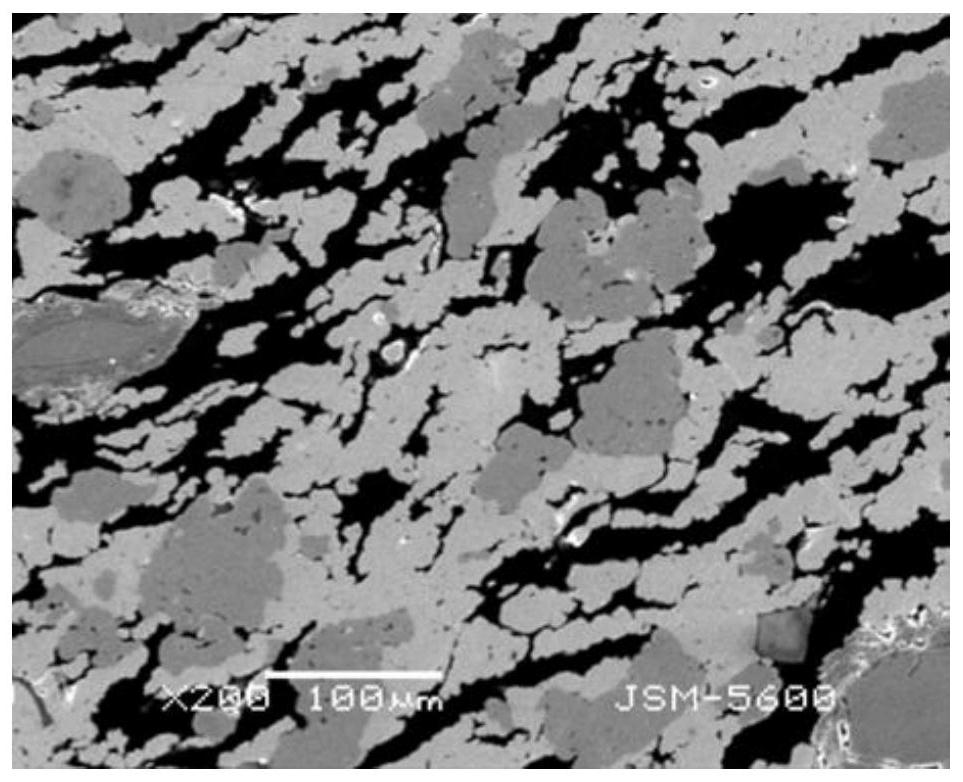

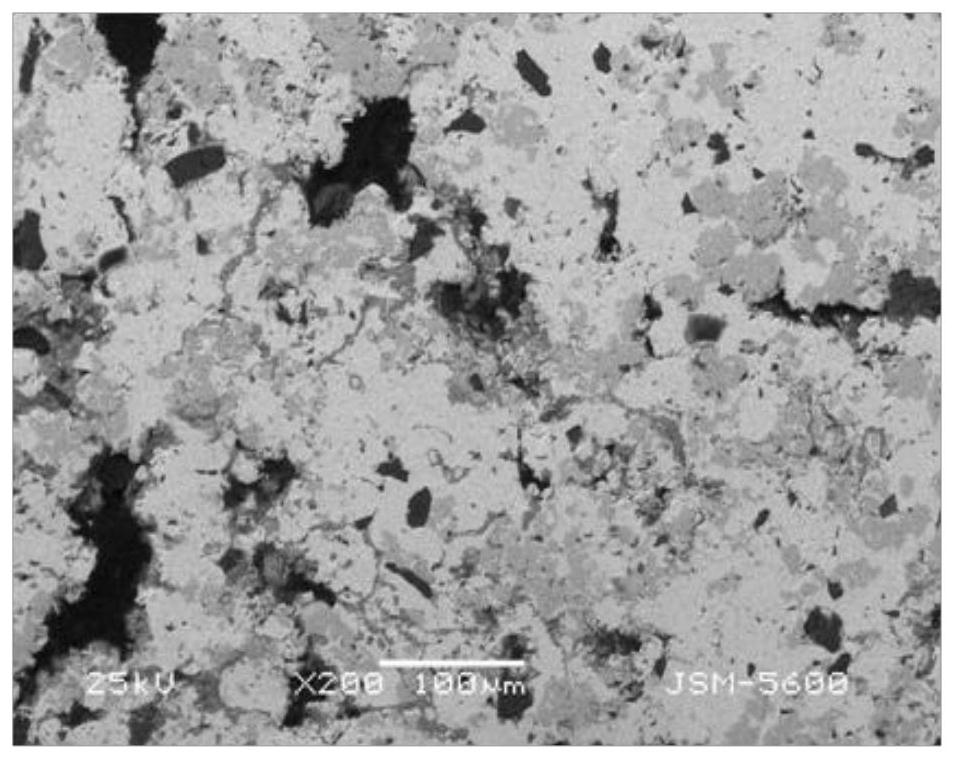

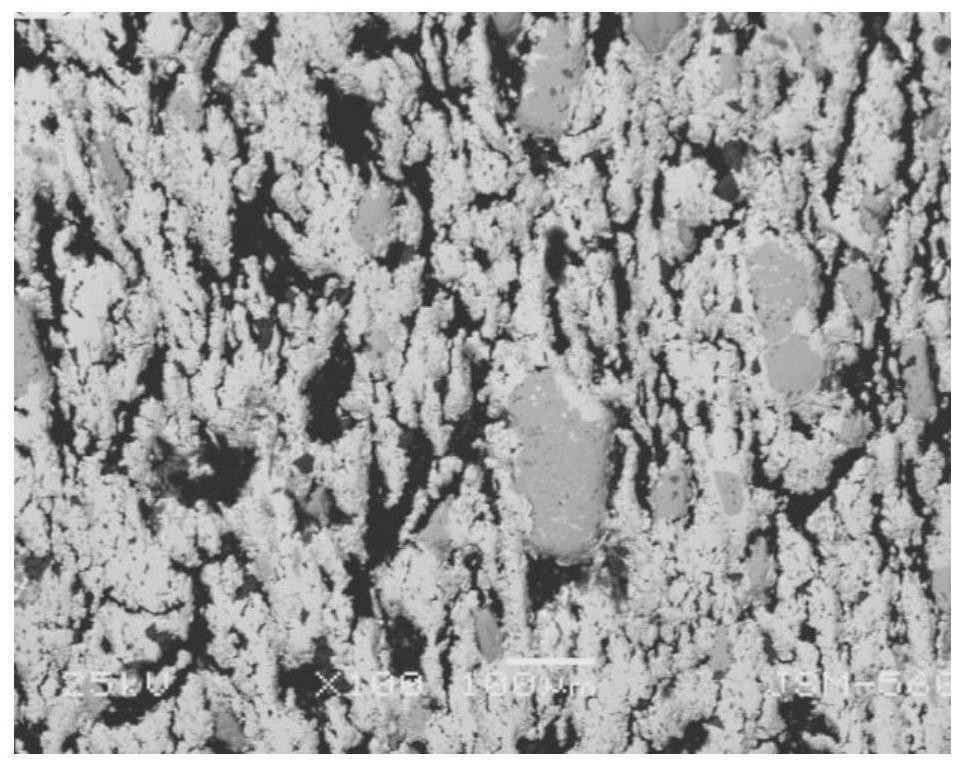

Image

Examples

Embodiment 1

[0042] Take 604g of copper powder, 203g of iron powder, 58g of tin powder, 10g of chromium powder, 10g of silicon dioxide, TiO 2 15g, graphite 100g, graphite sheet length is 200-400μm, width is 180-200μm, thickness is 25-30μm; firstly mix other materials except graphite fully according to the composition ratio, then add graphite and mix well; mix The finished powder is cold-pressed at a pressure of 560 MPa, and kept for 3 minutes after forming; it is sintered under a hydrogen atmosphere at a temperature of 1120° C., and the sintering time is 40 minutes.

Embodiment 2

[0044] Take 616g of copper powder, 185g of iron powder, 43g of tin powder, 6g of chromium powder, 20g of silicon dioxide, TiO 2 25g, graphite 105g, graphite sheet length is 200-400μm, width is 180-200μm, thickness is 25-30μm; firstly mix other materials except graphite fully according to the composition ratio, then add graphite and mix well; mix The finished powder is cold-pressed at a pressure of 560 MPa, and kept for 3 minutes after forming; it is sintered under a hydrogen atmosphere at a temperature of 1120° C., and the sintering time is 40 minutes.

Embodiment 3

[0046] Take 609g of copper powder, 200g of iron powder, 50g of tin powder, 6g of chromium powder, 10g of silicon dioxide, TiO 2 20g, graphite 105g, graphite flake length is 200-400μm, width is 180-200μm, thickness is 25-30μm; firstly mix other materials except graphite thoroughly according to the composition ratio, then add graphite and mix fully and evenly; mix The finished powder is cold-pressed at a pressure of 560 MPa, and kept for 3 minutes after forming; it is sintered under a hydrogen atmosphere at a temperature of 1120° C., and the sintering time is 40 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com