Preparation method and application of multilayer functional stent with controllable three-dimensional structure

A three-dimensional structural and functional technology, applied in the field of medical materials, can solve problems such as narrowing the application scope of multi-layer stents, and achieve the effects of strong capillary force, simple process and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

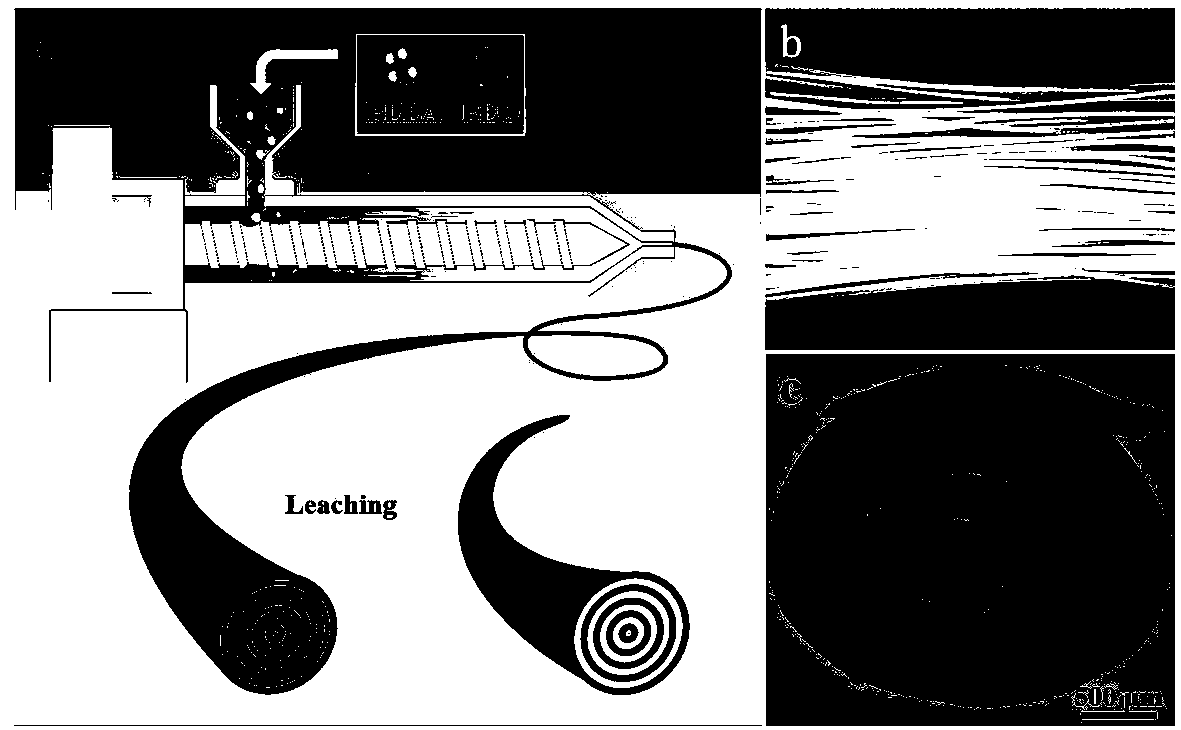

[0038] A method for preparing a multilayer functional scaffold with a controllable three-dimensional structure, comprising the following steps:

[0039] Step 1: Put 800g PLLA pellets and 1200g PEO pellets in an oven at 40°C, dry for 12 hours, dry the water, put them in a super large ziplock bag and mix them evenly, then put them in a single-screw extruder for melting Blend and extrude strands at an extrusion temperature of 170° C. and a screw speed of 20 rpm / min.

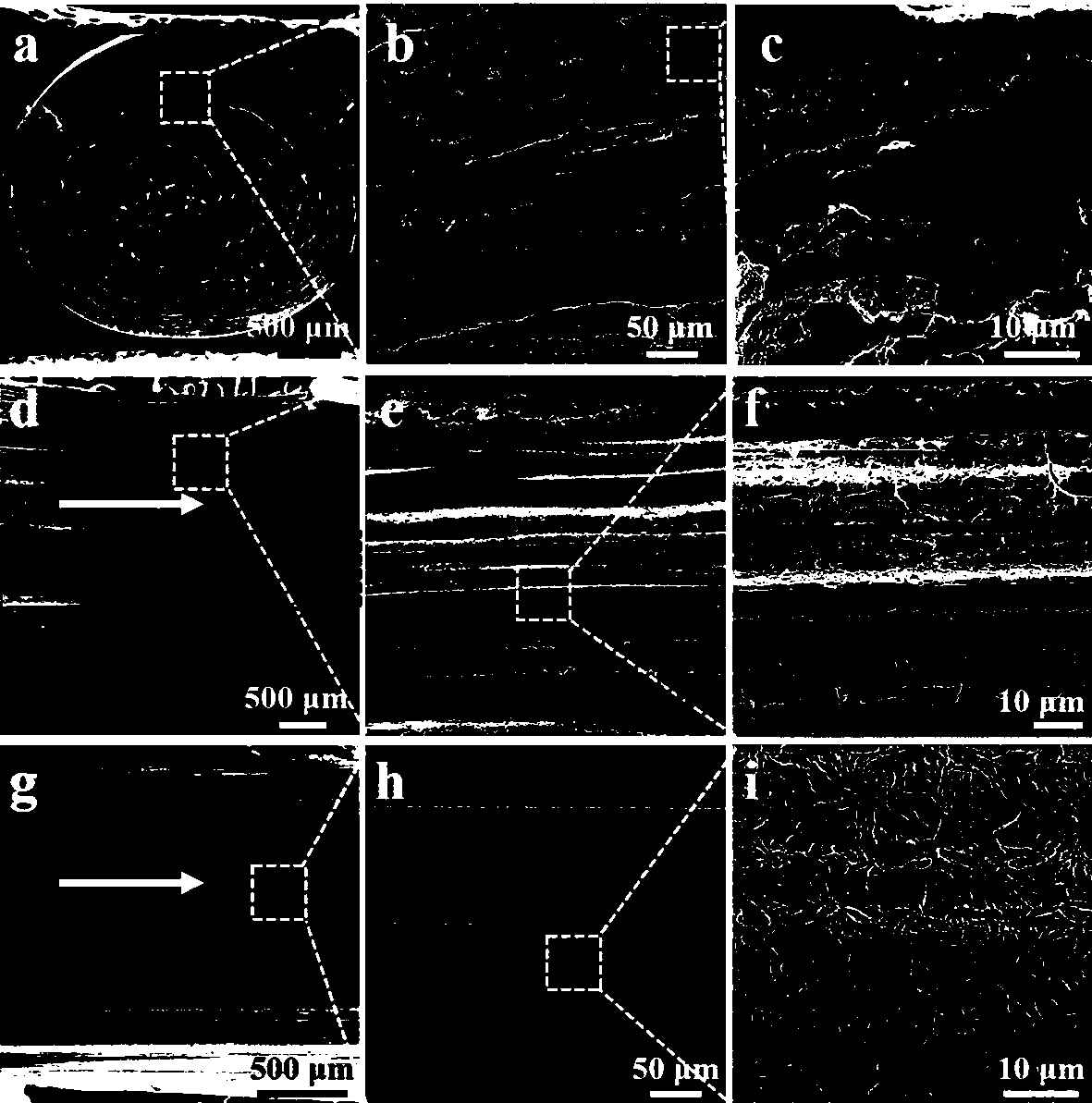

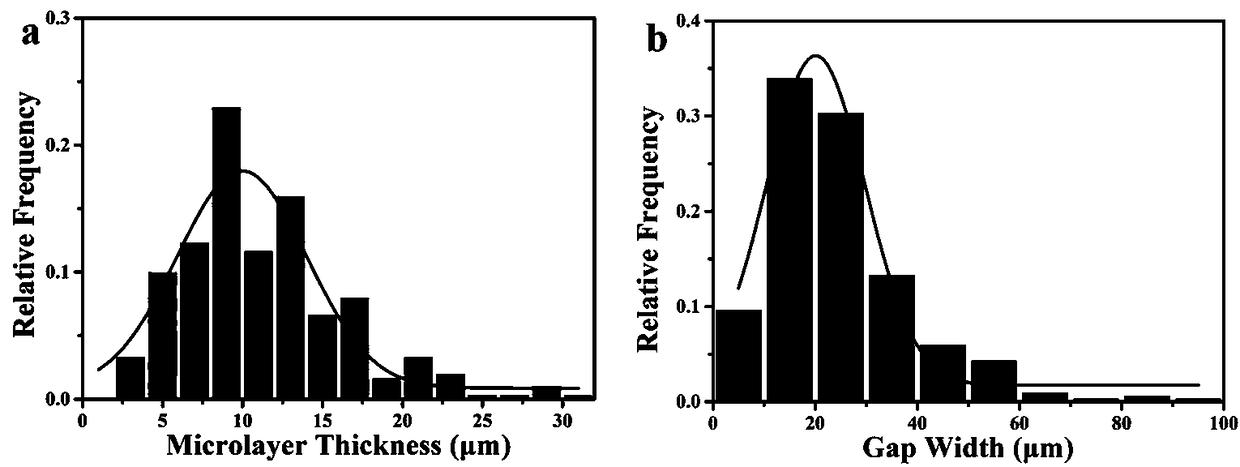

[0040] Step 2: Use a three-roller calender to cool the strip obtained in step 1 without stretching, and then cut it into a strip with a length of 40 cm to obtain a polylactic acid / polyethylene oxide with an alternating multi-layer concentric cylindrical structure. alkanes extrudates.

[0041] Step 3: Cut the polylactic acid / polyethylene oxide extrudate obtained in step 2 into strips with a length of 10 mm, and then fix them in custom-made triangular, rectangular and oval molds, and vacuum film laminator The temper...

Embodiment 2

[0049] A method for preparing a multilayer functional scaffold with a controllable three-dimensional structure, comprising the following steps:

[0050] Step 1: Put 800g PLLA pellets and 1200g PEO pellets in an oven at 30°C, dry for 24 hours, dry the water, put them in a super large ziplock bag and mix them evenly, then put them in a single-screw extruder for melting Blend and extrude strands at an extrusion temperature of 170° C. and a screw speed of 40 rpm / min.

[0051] Step 2: Use a three-roll calender to cool the strip obtained in step 1 without stretching, and then cut it into a strip with a length of 60 cm to obtain a polylactic acid / polyethylene oxide with an alternating multi-layer concentric cylindrical structure. alkanes extrudates.

[0052] Step 3: Cut the polylactic acid / polyethylene oxide extrudate obtained in step 2 into strips with a length of 10 mm, and then fix them on a three-jaw chuck and place them under a micro electric drill. The drill bits of 0.6mm and...

Embodiment 3

[0056] A method for preparing a multilayer functional scaffold with a controllable three-dimensional structure, comprising the following steps:

[0057] Step 1: Put 800g PLLA pellets and 1200g PEO pellets in an oven at 40°C, dry for 24 hours, dry the water, put them in a super large ziplock bag and mix them evenly, then put them in a single-screw extruder for melting Blend and extrude strands at an extrusion temperature of 170° C. and a screw speed of 30 rpm / min.

[0058] Step 2: Use a three-roller calender to cool the strip obtained in step 1 without stretching, and then cut it into a strip with a length of 40 cm to obtain a polylactic acid / polyethylene oxide with an alternating multi-layer concentric cylindrical structure. alkanes extrudates.

[0059] Step 3: Cut the polylactic acid / polyethylene oxide extrudate obtained in step 2 into a strip with a length of 20 mm, and wind an enameled wire with a diameter of 0.1 mm to the surface of the strip in a spiral manner. There is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com