A fully inorganic perovskite solar cell and a preparation method thereof

A technology of solar cells and inorganic calcium, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low open circuit voltage of all-inorganic perovskite solar cells, reduced photoelectric conversion efficiency of devices, and low photoelectric conversion efficiency. Enhanced extraction capability, improved open circuit voltage and device performance, and reduced electron-hole recombination effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

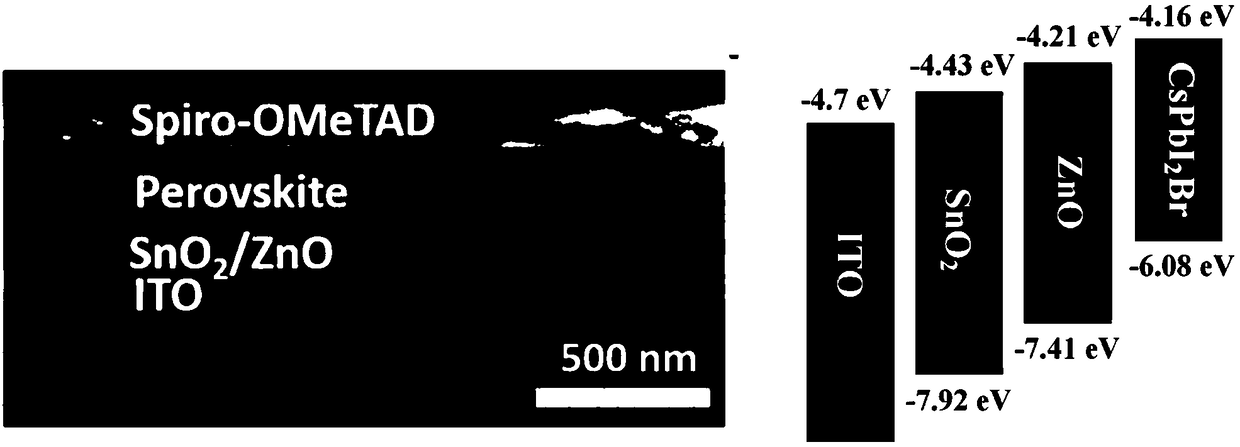

[0040] A method for preparing an all-inorganic perovskite solar cell device, comprising the steps of:

[0041] (1) The glass substrate coated with the ITO layer is ultrasonically cleaned with acetone, micron semiconductor detergent, deionized water, and isopropanol in sequence, and dried in a constant temperature oven for later use.

[0042] (2) Before use, place the dried substrate in step (1) in a petri dish, and place it in a vacuum plasma cleaner for 4 minutes. Then SnO 2 Solution (15wt%in H 2 O colloidal dispersion, purchased from Alfa Aesar) was spin-coated on the ITO layer, the spin-coating condition was 4000r / min for 30s, and the film thickness was 30nm to obtain SnO 2 electron transport layer.

[0043] (3) The n-butanol solution of ZnO nanoparticles (5 mg mL -1 ) spin-coated on the SnO prepared in step (2) 2 On the electron transport layer, a ZnO electron transport layer was prepared as the second electron transport layer. The spin coating rate was 5500r / min, the...

Embodiment 2

[0050] A method for preparing an all-inorganic perovskite solar cell device, comprising the steps of:

[0051] (1) The glass substrate coated with the ITO layer is ultrasonically cleaned with acetone, micron semiconductor detergent, deionized water, and isopropanol in sequence, and dried in a constant temperature oven for later use.

[0052] (2) Before use, place the dried substrate in step (1) in a petri dish, and place it in a vacuum plasma cleaner for 4 minutes. Then SnO 2 Solution (15wt%in H 2 O colloidal dispersion, purchased from Alfa Aesar) was spin-coated on the ITO layer, the spin-coating rate was 5000r / min, the spin-coating time was 30s, and the film thickness was 20nm to obtain SnO 2 electron transport layer.

[0053] (3) The n-butanol solution of ZnO nanoparticles (5 mg mL -1 ) spin-coated on the SnO prepared in step (2) 2 On the electron transport layer, a ZnO electron transport layer was prepared as the second electron transport layer. The spin coating rate ...

Embodiment 3

[0060] A method for preparing an all-inorganic perovskite solar cell device, comprising the steps of:

[0061] (1) The glass substrate coated with the ITO layer is ultrasonically cleaned with acetone, micron semiconductor detergent, deionized water, and isopropanol in sequence, and dried in a constant temperature oven for later use.

[0062] (2) Before use, place the dried substrate in step (1) in a petri dish, and place it in a vacuum plasma cleaner for 4 minutes. Then SnO 2 Solution (15wt%in H 2 O colloidal dispersion, purchased from Alfa Aesar) was spin-coated on the ITO layer, the spin-coating rate was 6500r / min, the spin-coating time was 30s, and the film thickness was 10nm to obtain SnO 2 electron transport layer.

[0063] (3) The n-butanol solution of ZnO nanoparticles (5 mg mL -1 ) spin-coated on the SnO prepared in step (2) 2 On the electron transport layer, a ZnO electron transport layer was prepared as the second electron transport layer, the spin-coating rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com