Water-stopping and thermal-insulation compound powder

A composite powder and water-stop technology, which is applied in building components, climate change adaptation, climate sustainability, etc., can solve problems such as furnace damage, non-decomposition by organisms, and heavy loads in landfills, so as to reduce consumption, The effect of preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

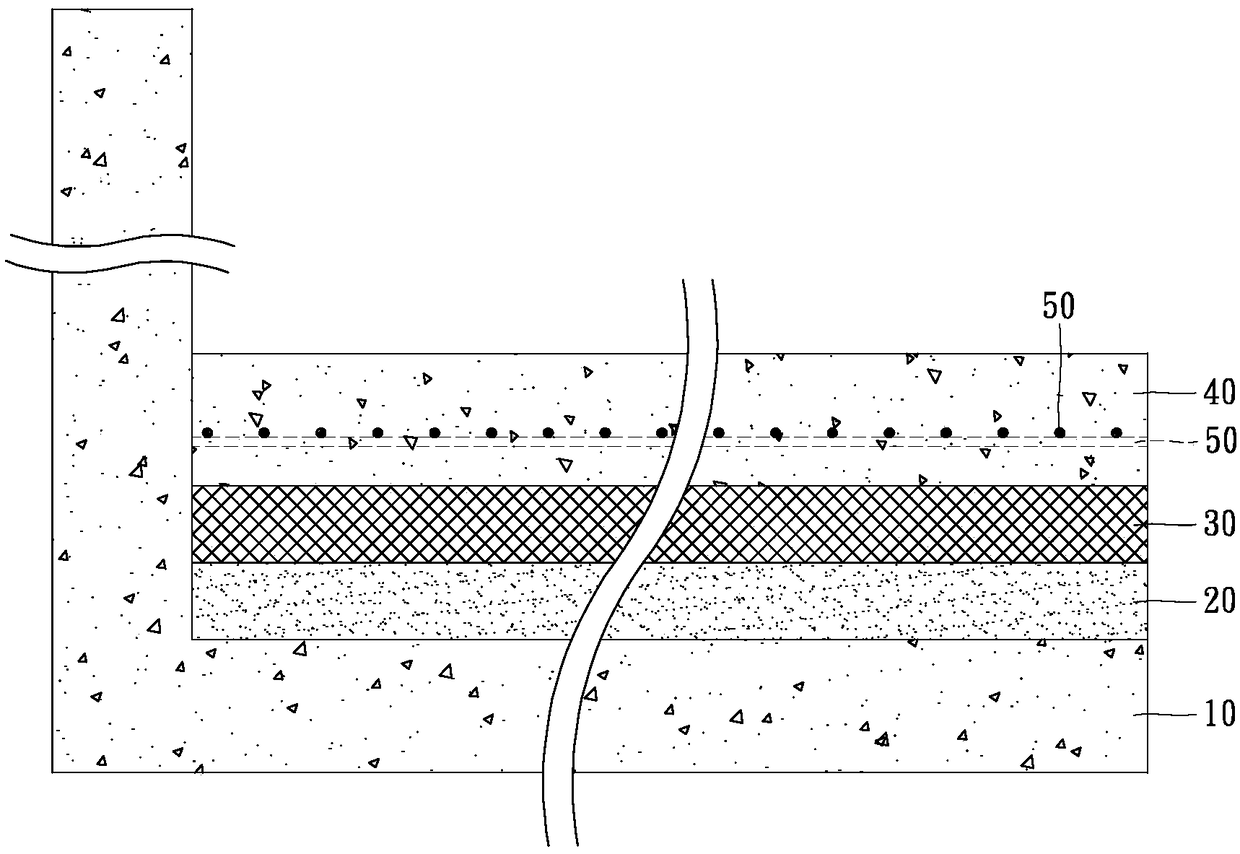

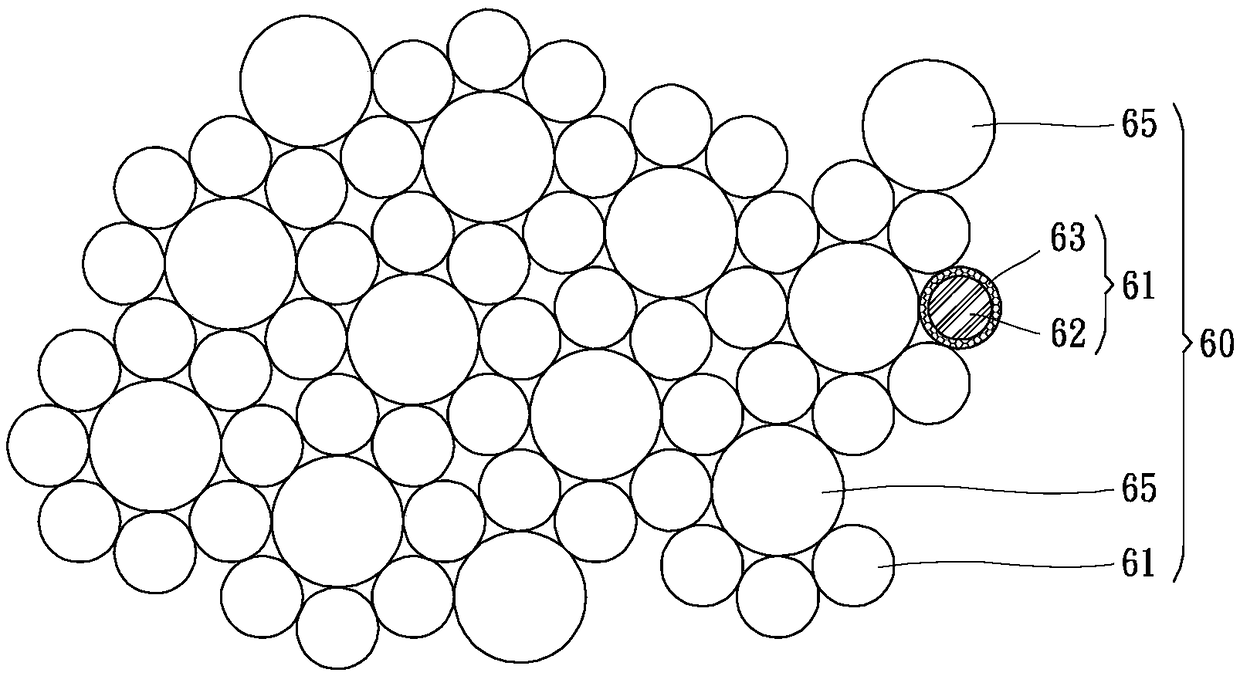

Method used

Image

Examples

Embodiment 1~5 and comparative example 1

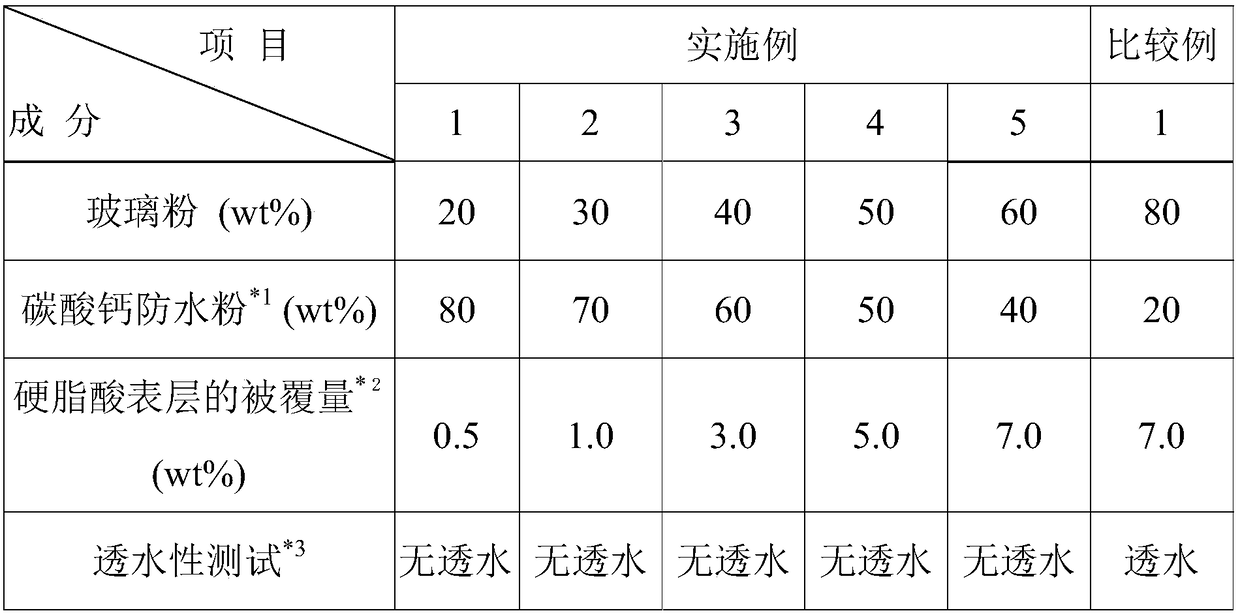

[0043] The water-stop and heat-insulation composite powder samples of each embodiment and comparative example were mixed and prepared according to the composition ratio in Table 1, and the water permeability of each sample was tested; the test results are shown in Table 1. Among them, the water-stop and heat-insulating composite powder samples of Examples 1-5 have the water-stop and leak-proof effect without water seepage, while the water-stop and heat-insulation composite powder sample of Comparative Example 1 cannot achieve the water-stop and leak-proof effect.

[0044] Table 1

[0045]

[0046] Note: 1. Calcium carbonate waterproof powder is modified and has a core-shell structure, and the shell structure is the surface layer of stearic acid.

[0047] 2. The coating amount of stearic acid surface layer is based on the total weight of calcium carbonate waterproof powder.

[0048] 3. Referring to the CNS 13777 (2008) specification in Taiwan, China, using a calcium silicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com