A kind of short fiber reinforced oriented max phase ceramic matrix composite material and preparation method

A technology of short fiber reinforcement and composite materials, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science. It can solve the problems of high reaction synthesis temperature, low strength, and performance degradation, and reduce the sintering reaction. The effect of good adaptability to temperature and technology and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In this example, the preparation method of the short fiber reinforced oriented MAX phase ceramic matrix composite material is as follows:

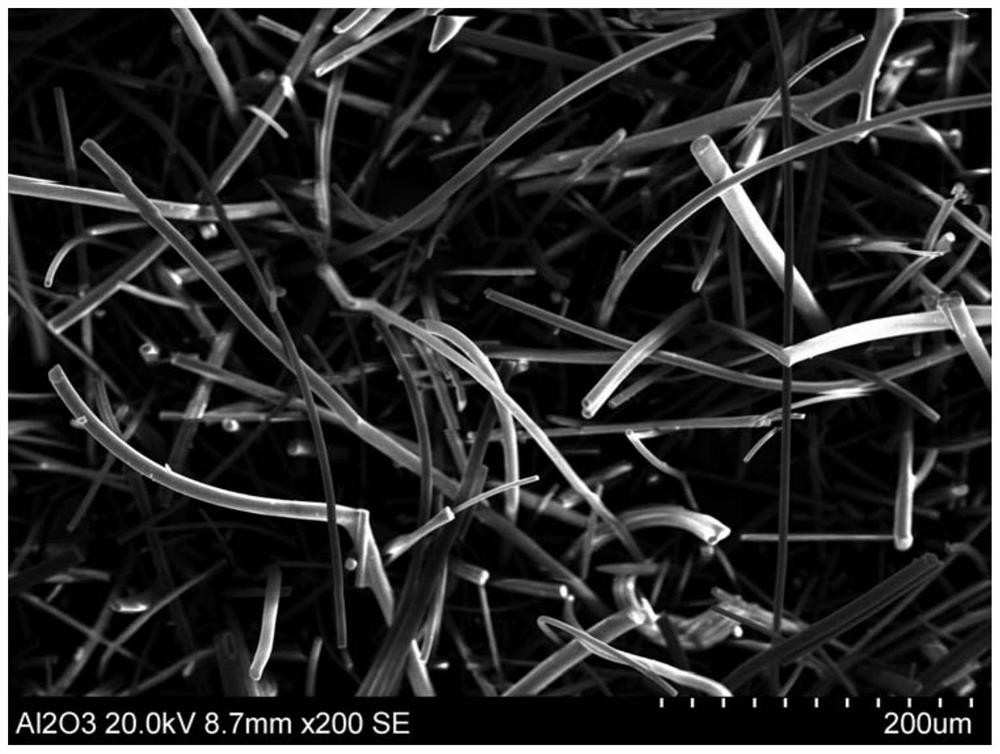

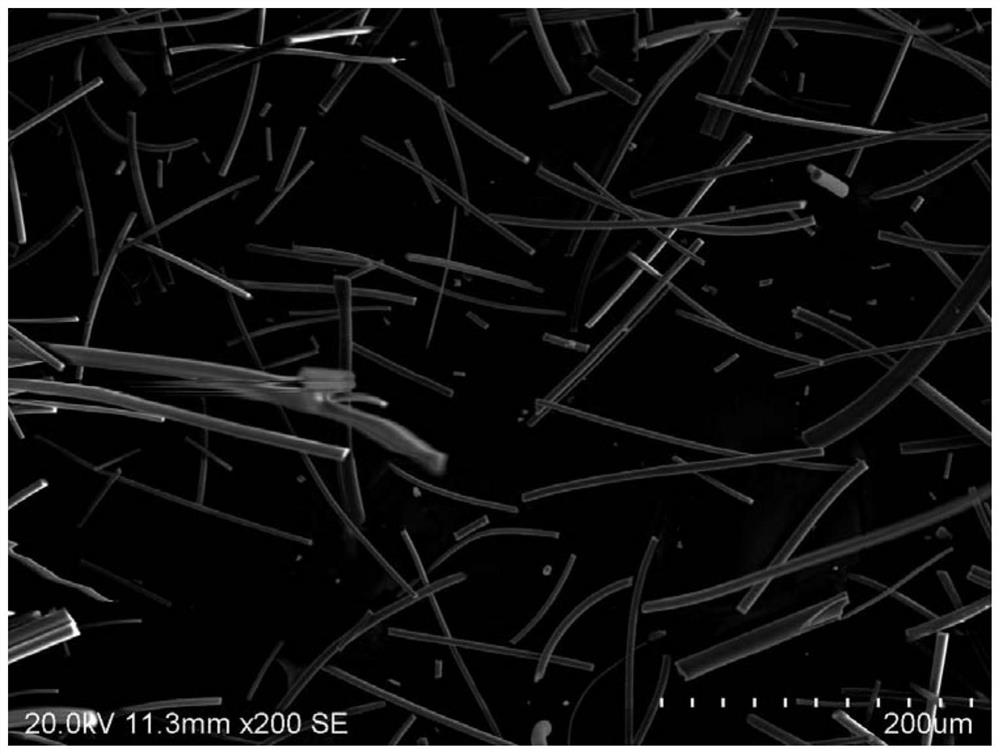

[0049] Weigh 200 grams of product name Ti 2 The nano MAX phase ceramic lamellar powder of AlC has a particle size of 180 nanometers and an oxygen content of 8% by mass. weigh figure 1 40 grams of the shown alumina fiber raw cotton, the fiber raw cotton is pretreated to obtain figure 2 Shown are short fibers with a fiber diameter of 3-10 microns and a fiber length of about 50-200 microns. Directly put the nanosheet powder and short fibers into a 1L beaker, add 200 grams of absolute ethanol for electric mechanical stirring, and the stirring blade speed is 200 rpm. After stirring for 1 hour, the slurry was taken out and dried. After the slurry is completely dried, put the obtained mixture into the mixer, and add a small amount of polyurethane-coated iron core balls with a diameter of 10 mm for mixing. The circular motion speed of ...

Embodiment 2

[0055] In this example, the preparation method of the short fiber reinforced oriented MAX phase ceramic matrix composite material is as follows:

[0056] Weigh 200 grams of product name Ti 3 SiC 2 The nanometer MAX phase ceramic sheet powder, the particle size of the powder is 220 nanometers, and the mass fraction of oxygen content in the powder is 0.0002%. Weigh 50 grams of chopped silicon carbide fibers with a diameter of 100-200 microns and a fiber length of about 3-5 mm, and add 30 grams of SiC particles with a particle size of 50 nanometers as an additive. Directly put the nanosheet powder, short fibers and SiC particles into the mixer, and add a small amount of polyurethane-coated iron core balls with a diameter of 10 mm for mixing. The circular motion speed of the mixing tank is 60 rpm, and the mixing time is After 4 hours, argon protection was introduced into the mixing tank. After the mixing is completed, in the vacuum glove box, the polyurethane iron core balls ar...

Embodiment 3

[0059] In this example, the preparation method of the short fiber reinforced oriented MAX phase ceramic matrix composite material is as follows:

[0060] Weigh 200 grams of product name Ti 3 AlC 2The nanometer MAX phase ceramic sheet powder, the particle size of the powder is 200 nanometers, and the mass fraction of oxygen content in the powder is 0.0002%. Weigh 50 grams of chopped C fibers with a diameter of 20-50 microns and a fiber length of about 3-5 mm, and add 10 grams of polyethylene particles with a particle size of 50 nanometers as a reaction additive. Directly put the nanosheet powder, short fiber and polyethylene into the mixer, and add a small amount of polyurethane-coated iron core balls with a diameter of 10 mm for mixing. The circular motion speed of the mixing tank is 30 rpm, and the mixing time is After 12 hours, argon protection was introduced into the mixing tank. After the mixing is completed, in the vacuum glove box, the polyurethane iron core balls are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com