Mineral powder combined fiber composite board as well as production method and application

A technology combining fibers and composite boards, applied in chemical instruments and methods, building materials, wood-layered products, etc., can solve the problems of low service life, non-fireproof construction cost, poor mechanical properties, etc. The effect of good sound insulation and heat preservation, excellent fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

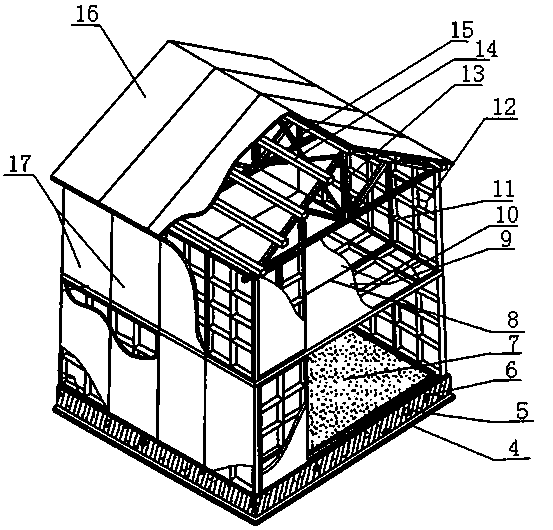

Image

Examples

Embodiment 1

[0040] A kind of ore powder combined fiber composite plate, comprising the following components in parts by mass: 10% of magnesium chloride, 21% of magnesium oxide, 4% of plant fiber silk, 54% of wood board, and the balance is water.

[0041] The manufacturing method of ore powder combined with fiber composite plate comprises the following steps:

[0042] In the first step, magnesium chloride, magnesium oxide and water are mixed and stirred evenly to obtain a mixture;

[0043] In the second step, take half of the mixture and lay it evenly on the bottom of the mold as the mixture layer I;

[0044] The third step is to take half of the plant fiber silk and spread it evenly on the mixture layer I as the plant fiber silk layer I, lightly press the plant fiber silk layer I to fully combine with the mixture layer I;

[0045] The fourth step is to lay planks on the plant fiber layer I as the plank layer;

[0046] The fifth step is to evenly lay a layer of remaining mixture on the p...

Embodiment 2

[0052] An ore powder combined fiber composite plate, comprising the following components in parts by mass: 12% of magnesium chloride, 23% of magnesium oxide, 6% of plant fiber silk, 58% of wood board, and the balance is water.

[0053] The manufacturing method of ore powder combined with fiber composite plate comprises the following steps:

[0054] In the first step, magnesium chloride, magnesium oxide and water are mixed and stirred evenly to obtain a mixture;

[0055] In the second step, take half of the mixture and lay it evenly on the bottom of the mold as the mixture layer I;

[0056] The third step is to take half of the plant fiber silk and spread it evenly on the mixture layer I as the plant fiber silk layer I, lightly press the plant fiber silk layer I to fully combine with the mixture layer I;

[0057] The fourth step is to lay planks on the plant fiber layer I as the plank layer;

[0058] The fifth step is to evenly lay a layer of remaining mixture on the plank la...

Embodiment 3

[0066] An ore powder combined with fiber composite plate, comprising the following components in parts by mass: 15% magnesium chloride, 25% magnesium oxide, 8% plant fiber silk, 60% wood board, and the balance is water.

[0067] The manufacturing method of ore powder combined with fiber composite plate comprises the following steps:

[0068] In the first step, magnesium chloride, magnesium oxide and water are mixed and stirred evenly to obtain a mixture;

[0069] In the second step, take half of the mixture and lay it evenly on the bottom of the mold as the mixture layer I;

[0070] The third step is to take half of the plant fiber silk and spread it evenly on the mixture layer I as the plant fiber silk layer I, lightly press the plant fiber silk layer I to fully combine with the mixture layer I;

[0071] The fourth step is to lay planks on the plant fiber layer I as the plank layer;

[0072] The fifth step is to evenly lay a layer of remaining mixture on the plank layer as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com