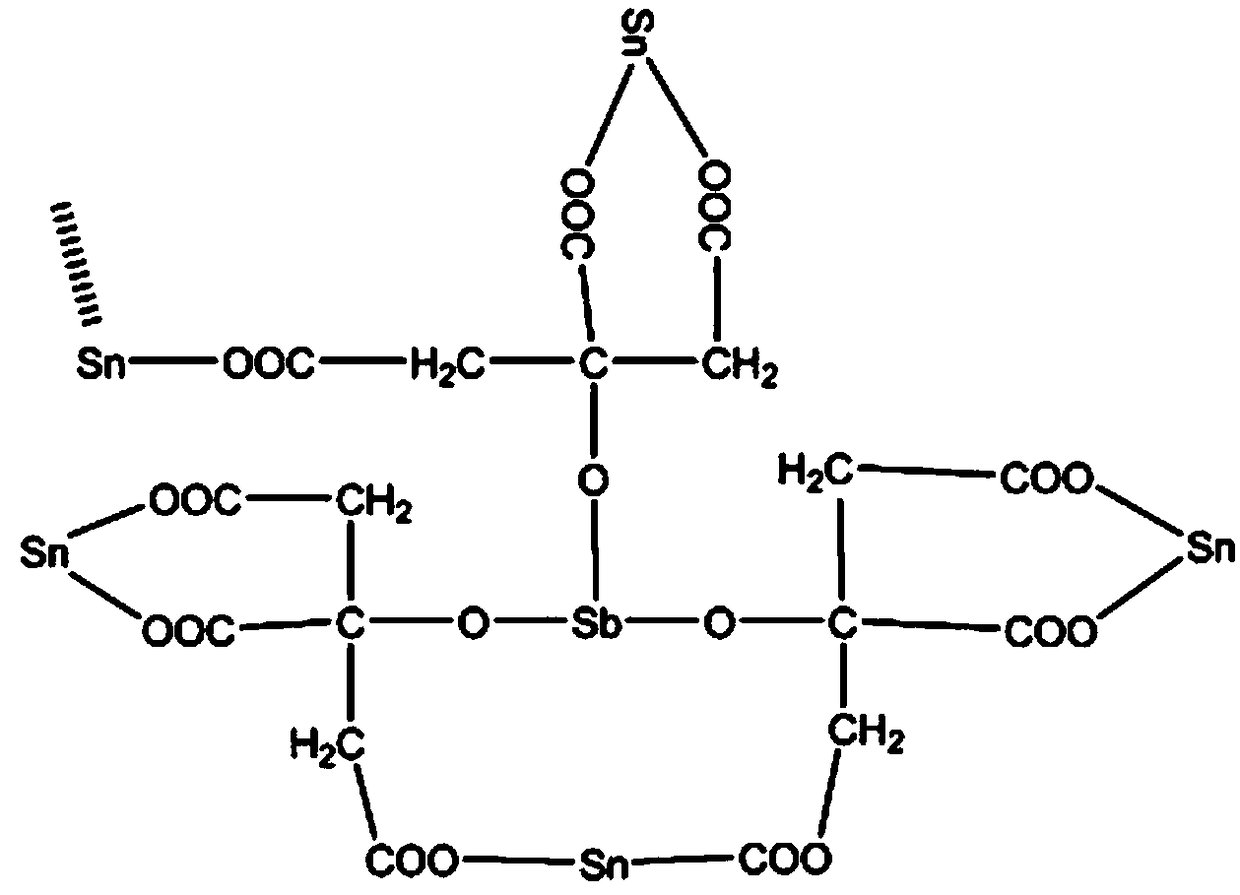

Method for preparing Ti/SnO2-Sb (titanium/tin dioxide-antimony) electrode by tricarboxylic organic acid-Sn(II)/Sb(III) complex

A sno2-sb, organic acid technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of poor coverage of prepared electrodes, uneven modification layer, hydrogen evolution side reaction, etc. , to achieve the effect of suppressing the hydrogen evolution side reaction, depositing a complete coating, and good coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

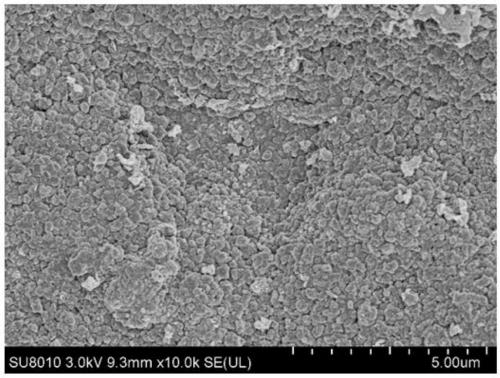

[0034] Use SnCl 2 Preparation of ATO electrode by electrodeposition using citric acid as a complexing agent as tin source

[0035] The specific steps of ATO electrode production are as follows: First, take a 20×20×0.65mm Ti sheet (purity 99.9%) and polish it with 400-mesh and 800-mesh sandpaper in turn, then spot weld and connect titanium wire as a conductor; wash with deionized water After cleaning, soak in NaOH solution with a mass concentration of 40wt% at 80°C for 0.5h. After soaking, wash and boil in an oxalic acid solution with a mass concentration of 10wt%. Reserve in ethanol solution.

[0036] The configuration method of the electrodeposition solution is: weigh 5.4g SnCl 2 2H 2 O, 0.18g SbCl 3 and 4.6g of citric acid were dissolved in 80mL of deionized water to form a transparent solution; after the solution was heated to 50°C in a water bath, 0.024g of gelatin was added and stirred until completely dissolved, then cooled to room temperature. In the electrodeposit...

specific Embodiment 2

[0041] This example compares the performance of the electrode prepared by the method of the present invention and the ATO electrode prepared by the electrodeposition method reported in the literature in the treatment of methylene blue simulated wastewater. In this embodiment, the electrode preparation steps of the present invention are the same as those in the specific example 1.

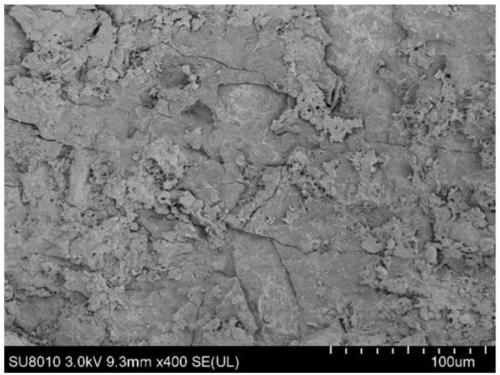

[0042] The specific steps for preparing the ATO electrode using the electrodeposition method reported in the literature are: the pretreatment method of the Ti sheet is the same as in Example 1; the configuration of the electrodeposition solution is to weigh 2.6g SnCl 4 ·5H 2 O; 0.164 g SbCl 3 and 1.2g of tartaric acid were dissolved in 80ml of deionized water; the pretreated Ti sheet was vertically immersed in the prepared electrodeposition solution, and two smooth graphite sheets with a diameter of 3.5cm and a thickness of 1mm were symmetrically placed on the Ti sheet On both sides, the distance ...

specific Embodiment 3

[0044] The electrode prepared by the method of the present invention is compared with a commercially purchased boron-doped diamond film (BDD) electrode for degrading methylene blue simulated wastewater.

[0045] In this embodiment, the electrode preparation steps of the present invention are the same as those in Embodiment 1; the BDD electrode is purchased from Neocoat, Switzerland, the electrode size is 20mm×20mm×1mm, the specification is that the diamond film thickness is 5 μm, the boron doping concentration is 2500ppm, and the base material is Nb , double-sided modification. The specific steps of the methylene blue simulated wastewater degradation are the same as in the specific implementation 2. Using different anode materials, the degradation curve of methylene blue is as follows Figure 5 As shown, the first-order degradation kinetics fitting is carried out to the degradation results of each electrode, and the first-order degradation kinetic rate constants of the specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com