Method for manufacturing additives by combining selective laser melting and laser cutting

A laser selective melting and laser cutting technology, applied in the field of additive manufacturing, can solve the problems of short molten pool existence time, large temperature gradient, and increased voids in parts, and achieve the effect of improving smoothness, eliminating cracks and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

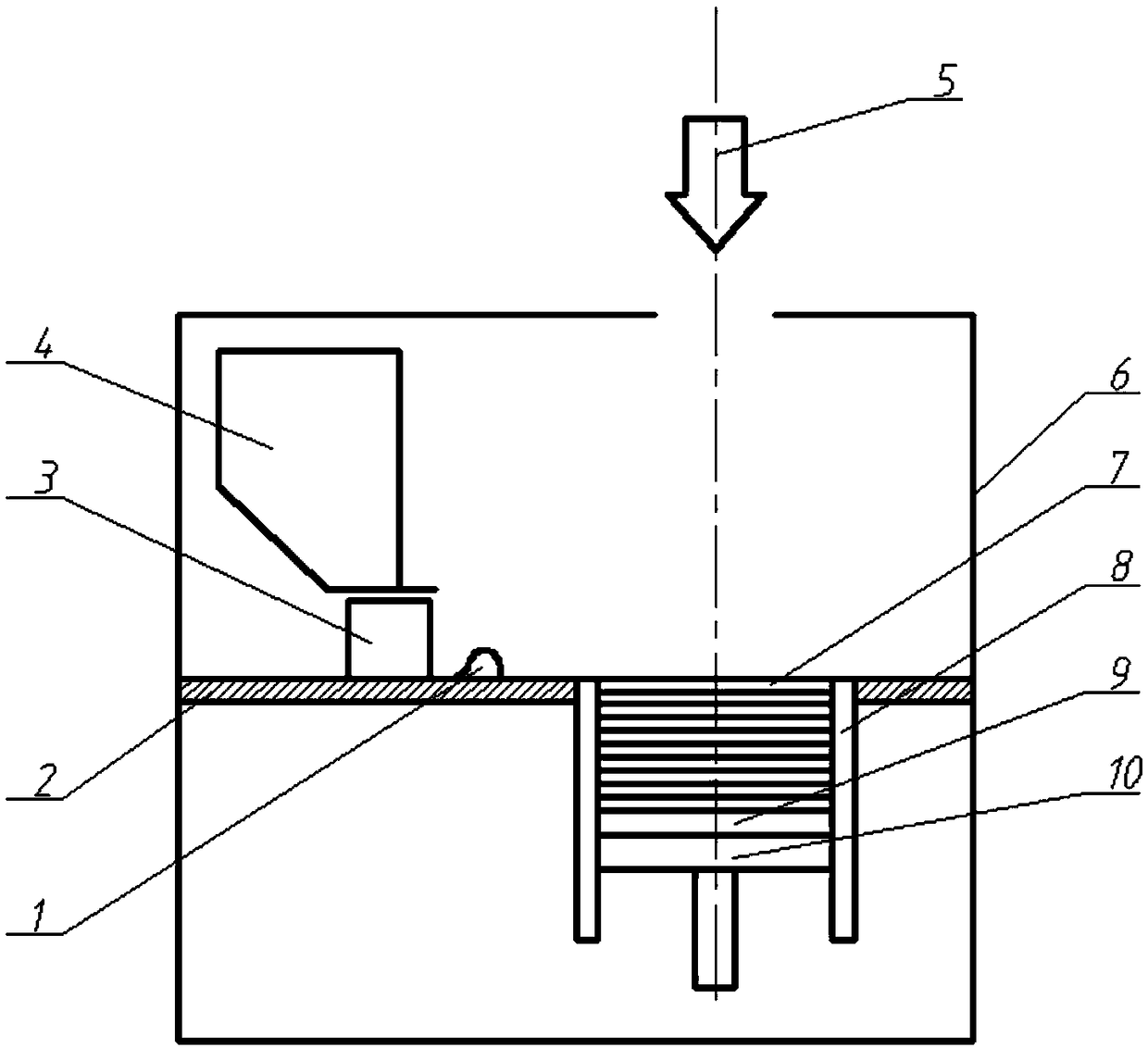

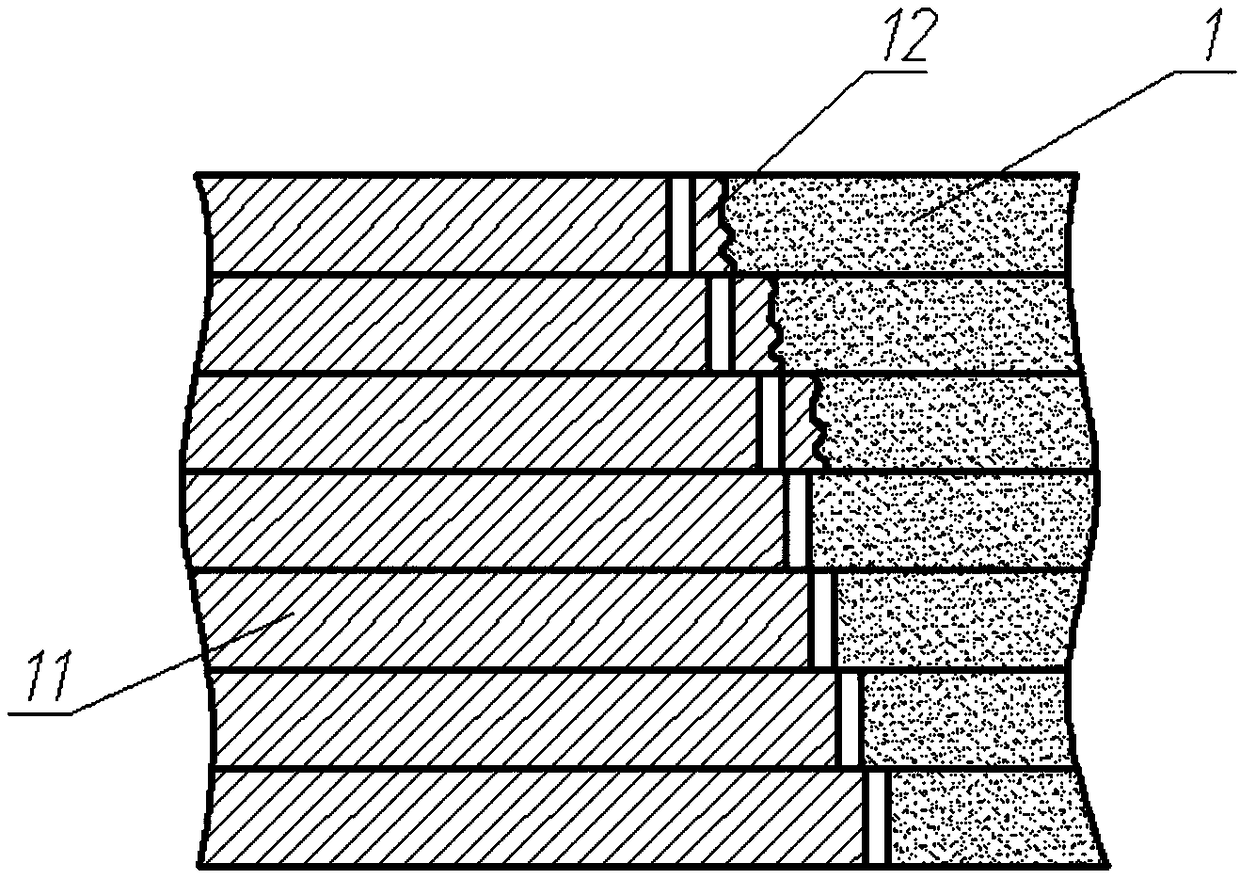

[0025] refer to figure 1 and figure 2 , the present embodiment relates to a combined additive manufacturing method of laser selective melting and laser cutting, comprising the following steps:

[0026] 1) Clean the surface of the TC4 substrate with an alkaline solution to remove oil stains, then polish and remove the oxide film on the surface of the substrate 9 and wipe it dry with acetone; A height difference of powder layer thickness is formed on the surface of the surface; under the control of the control computer, the powder feeder 4 outputs a certain amount of TC4 powder 1 and falls on the surface of the working platform 2, and then the powder laying device 3 pushes the TC4 powder 1 to the forming In the cylinder 8 and flat on the forming area of the substrate 9 .

[0027] 2) First emit the laser beam 5 in the heating mode to scan and preheat the TC4 powder bed 7 to heat the TC4 powder to the micro-sintering temperature of 581°C to produce micro-sintering, wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com