Safety protector for electric power failure overhauling

A power failure and safety technology, used in seat belts, manufacturing tools, tool storage devices, etc., can solve the problem of inconvenient carrying of aerial work tools, and achieve the effect of excellent mechanical performance and anti-static performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

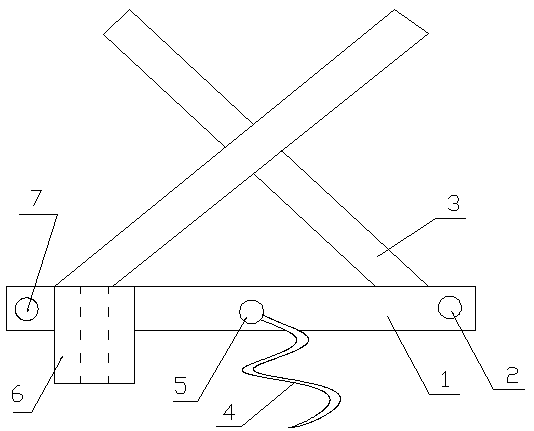

[0032] refer to figure 1 , this embodiment provides a kind of safety protective equipment for electric power failure maintenance, including a safety belt body and a tool bag 6; the safety belt body includes a waist belt 1 and two shoulder belts 3 arranged on the waist belt 1 One end of the back shoulder strap 3 is fixedly arranged on one side of the waist belt 1, and the other end of the back shoulder strap 3 is cross-connected to the other side of the waist belt 3 around the shoulder of the human body. A self-locking hook 5 connected to the sling 4 is provided, a pull ring 2 is provided at one end of the belt 1, and a buckle 7 is provided at the other end; the tool bag 6 is arranged on the belt 1, and several A sealing strip divides the tool bag 6 into several subsections.

[0033] In this embodiment, one end of the back shoulder strap 3 is sewn on the waist belt 1, and the other end goes around the shoulder of the human body, and is connected to the other side of the waist ...

Embodiment 2

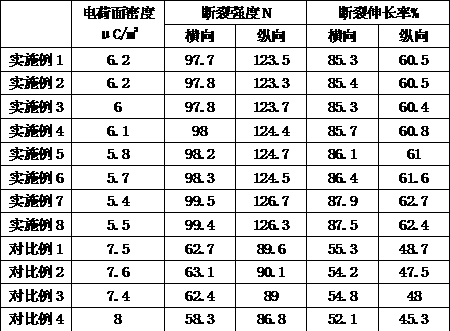

[0043] This embodiment provides a safety protective gear for power failure maintenance. The difference from Embodiment 1 is that the modified composite fiber is made of the components shown in Table 1 in parts by weight.

[0044] The flame retardant is tricresyl phosphate, the filler is montmorillonite, the antistatic agent is glyceryl monostearate, and the concentration of the sodium hydroxide solution is 11%.

[0045] The preparation method of described modified composite fiber comprises the following steps:

[0046] S1: Put polyethylene terephthalate, polyamide, 1,3-propanediol, bagasse, caprolactam, and water in a reaction kettle to mix and stir, pass in nitrogen, keep the pressure at 0.6MPa, stir for 3.5h, and rotate at a speed of 700r / min, the temperature is 120°C, and the mixed material is obtained;

[0047] S2: After the mixed material obtained in step S1 is cooled to room temperature, it is placed in a melt spinning machine for spinning, the screw temperature is 245°...

Embodiment 3

[0051] This embodiment provides a safety protective gear for power failure maintenance. The difference from Embodiment 1 is that the modified composite fiber is made of the components shown in Table 1 in parts by weight.

[0052] The flame retardant is ammonium polyphosphate, the filler is benzophenone, the antistatic agent is octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate, and the concentration of the sodium hydroxide solution is 12 %.

[0053] The preparation method of described modified composite fiber comprises the following steps:

[0054] S1: Put polyethylene terephthalate, polyamide, 1,3-propanediol, bagasse, caprolactam, and water in a reaction kettle to mix and stir, feed nitrogen, keep the pressure at 0.8MPa, stir for 3 hours, and rotate at 800r / min, the temperature is 130°C, and the mixed material is obtained;

[0055] S2: After cooling the mixed material obtained in step S1 to room temperature, it is placed in a melt spinning machine for spinning, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com