Method of indirectly detecting plastic deformation capacity of deformed aluminum alloy, and application

A plastic deformation, aluminum alloy technology, applied in the field of materials, can solve the problems of no report of electron paramagnetic resonance spectroscopy to detect the mechanical properties of metal materials, consumption of relatively large raw materials, errors in detection, etc., and achieve high contingency, simple sample processing, Overcome insurmountable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

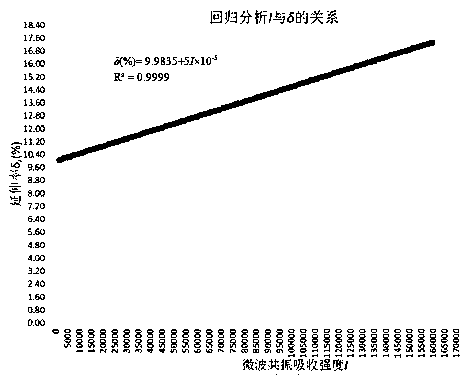

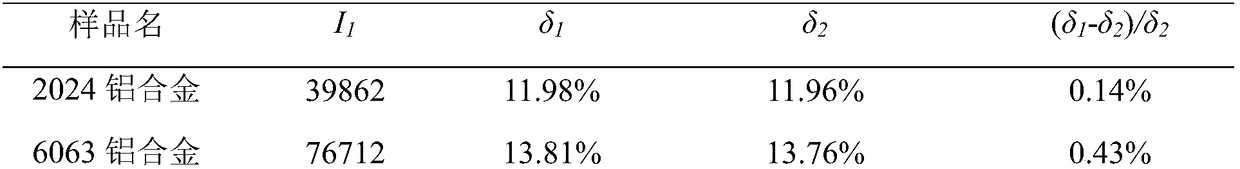

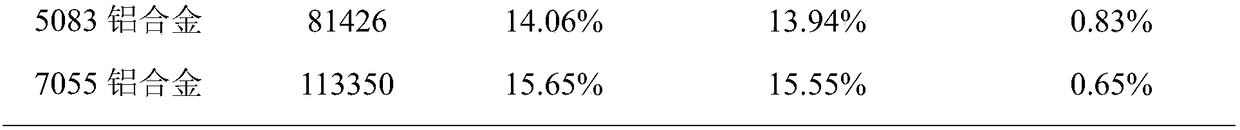

[0027] (1) Determination of microwave resonance absorption strength of deformed aluminum alloy:

[0028] The aluminum alloys used are all deformed aluminum alloys, including 2 series 2024, 5 series 5085, 6 series 6063 and 7 series 7055, each with 25 aluminum alloy samples. Before testing, the surface of the deformed aluminum alloy samples was cleaned to remove surface oil; The surface of the cleaned deformed aluminum alloy sample is detected by an electron paramagnetic resonance spectrometer for the electron paramagnetic resonance spectrum of the deformed aluminum alloy sample to obtain the characteristics of the number of unpaired electrons inside the alloy, which is characterized by microwave resonance absorption intensity I;

[0029] The electron paramagnetic resonance spectrometer is the A300-10 / 12 electron paramagnetic resonance spectrometer produced by Bruker, Germany. The equipment includes four parts: an electromagnetic wave generator providing resonance frequency; a st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com