Aqueous boron nitride coating capable of binding at low temperature and being used at high temperature

A technology of boron nitride and hexagonal boron nitride, which is applied in the direction of coating, etc., can solve the problems of limiting the application range of boron nitride coatings, cumbersome preparation steps, high bonding temperature, etc., and achieve low bonding temperature and long service life , the effect of firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

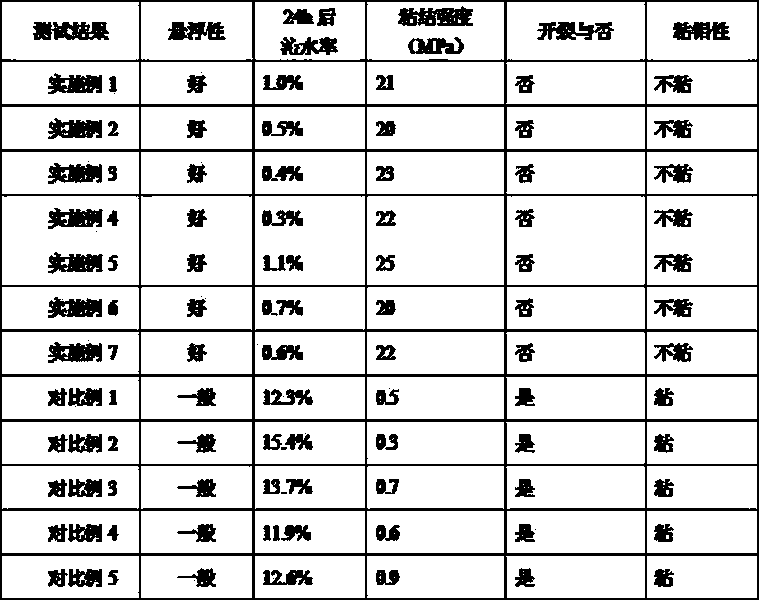

Examples

Embodiment 1

[0020] The water-based boron nitride coating that can be bonded at low temperature and used at high temperature in this embodiment is made of the following raw materials in weight ratio: 15% hexagonal boron nitride, 2% composite high-temperature binder, 1% carboxymethyl cellulose, Attapulgite 0.5%, cobalt aluminate 0.5%, isooctyl alcohol 0.5%, and the balance is demineralized water; the composite high-temperature binder is a mixture of silica sol and aluminum sol at a mass ratio of 1:3; hexagonal boron nitride It is made by mixing hexagonal boron nitride with a particle size of 10.0 μm to 30.0 μm and hexagonal boron nitride with a particle size of 0.5 μm to 3 μm at a mass ratio of 1:0.05.

[0021] The preparation method of the water-based boron nitride coating that can be bonded at low temperature and used at high temperature of the present embodiment is as follows:

[0022] At room temperature, first mix and stir the composite high-temperature binder, sodium carboxymethyl cel...

Embodiment 2

[0024] The water-based boron nitride coating that can be bonded at low temperature and used at high temperature in this embodiment is made of the following raw materials in weight ratio: 25% hexagonal boron nitride, 5% composite high-temperature binder, 1% carboxymethyl cellulose, 0.5% bentonite, 0.5% cobalt aluminate, 0.5% isooctyl alcohol, and the balance is demineralized water; the composite high-temperature binder is a mixture of silica sol and aluminum dihydrogen phosphate at a mass ratio of 1:5; hexagonal boron nitride It is made by mixing hexagonal boron nitride with a particle size of 10.0 μm to 30.0 μm and hexagonal boron nitride with a particle size of 0.5 μm to 3 μm at a mass ratio of 1:0.3.

[0025] The preparation method of the water-based boron nitride coating that can be bonded at low temperature and used at high temperature in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0027] The water-based boron nitride coating that can be bonded at low temperature and used at high temperature in this embodiment is made of the following raw materials in weight ratio: 30% hexagonal boron nitride, 8% composite high-temperature binder, 1% carboxymethyl cellulose, 0.5% sepiolite powder, 0.5% cobalt aluminate, 0.5% isooctanol, and the balance is demineralized water; the composite high-temperature binder is a mixture of silica sol and aluminum hydroxide at a mass ratio of 1:10; hexagonal nitriding Boron is a mixture of hexagonal boron nitride with a particle size of 10.0 μm to 30.0 μm and hexagonal boron nitride with a particle size of 0.5 μm to 3 μm at a mass ratio of 1:0.5.

[0028] The preparation method of the water-based boron nitride coating that can be bonded at low temperature and used at high temperature in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com