Electronic cutting device and metal fusing agent grain

A charge and fusing technology, applied in metal processing equipment, explosives, welding equipment, etc., can solve the problems that cutting tools cannot be carried quickly and work effectively, and are not applicable, and achieve a simple structure, low production cost, and easy to carry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

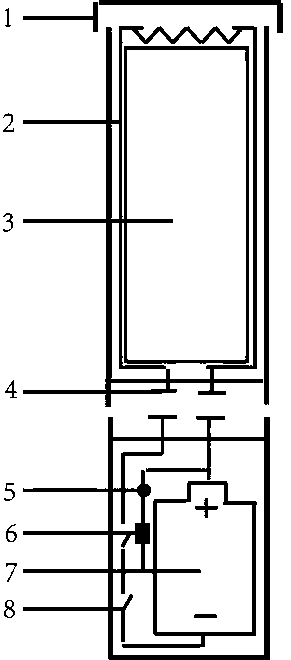

[0034] An electronic cutting device consists of an open casing 1 and a matching waterproof plug.

[0035] The shell 1 is divided into a control cavity and a grain cavity, and the grain cavity is placed at the open end of the shell 1; the grain cavity is used to accommodate the metal fusing reagent grain; the control cavity has a built-in drive circuit, including a metal wire 2 A battery 7, an indicator light 5, a resistor 6, a switch 8 arranged on the wall of the control cavity, and a heating resistor 6 wire arranged at the mouth of the grain column are connected in series.

[0036] The outer wall of the control cavity is provided with a handle, which is preferably made of insulating and non-slip material.

Embodiment 2

[0038] Based on an electronic cutting device in Example 1, the housing 1 is composed of a separable grain cavity and a control cavity; the control cavity is sealed, and the ends of the grain cavity and the control cavity are respectively provided with metal contact pieces 4, and the The metal contact piece 4 is connected to the driving circuit.

Embodiment 3

[0040] A metal fuse powder column 3 is composed of the following components by mass percentage: 60-70% of an oxidant, 15-25% of a reducing agent, 4-8% of an ignition agent, and 4-8% of a gas generator.

[0041] Among them, the oxidant is composed of ferric oxide, ferric tetroxide, copper oxide, cuprous oxide, manganese dioxide, manganese oxide, silicon dioxide, chromium oxide, boron oxide, beryllium oxide at least one constituent of lead;

[0042] The reducing agent is composed of at least one of aluminum powder, zinc powder, nickel powder, silicon powder and titanium powder;

[0043] The ignition agent is magnesium powder;

[0044] The gas generating agent is composed of at least one of potassium perchlorate, potassium chlorate, potassium nitrate and barium nitrate.

[0045] The preferred component 1 includes: ferric oxide 46%, copper oxide 23%; aluminum powder 20%; magnesium powder 4.5%; potassium perchlorate 6.5%.

[0046] And, 20% of the aluminum powder is composed of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com