Insulating ceramic for high voltage transmission lines, and preparation method thereof

A technology of high-voltage transmission lines and insulating ceramics, which is applied in the field of insulating materials, can solve problems such as damage to line service and operating life, insufficient insulation performance of insulators, and reduced product durability, so as to achieve reduced replacement costs, high smoothness, and long service life. prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

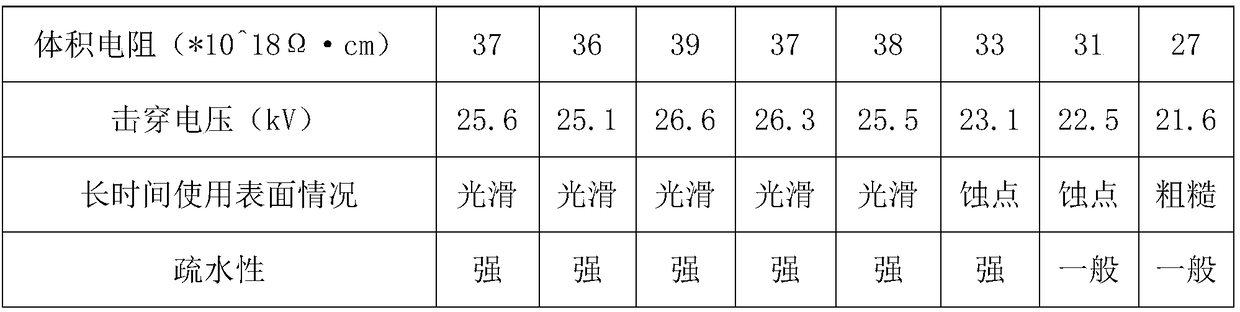

Examples

Embodiment 1

[0021] An insulating ceramic for high-voltage transmission lines, comprising the following raw materials in parts by weight: 20 parts of mica powder, 10 parts of titanium dioxide, 5 parts of calcite, 5 parts of calcite, 15 parts of aluminum oxide, 5 parts of cobalt oxide, and 10 parts of calcium carbonate , 10 parts of barium carbonate, 3 parts of silicon dioxide, 10 parts of Rhizoma chinensis, 15 parts of gum arabic, and 5 parts of gloss agent.

[0022] Wherein, the gloss agent is nonylphenol polyoxyethylene ether.

[0023] In this embodiment, the preparation method of the insulating ceramics for high-voltage transmission lines, the steps are as follows:

[0024] 1) Add the 85% ethanol solution with a concentration of 3 times of the weight multiple after crushing the ground root, stir evenly, seal and store at room temperature for 10 hours, remove the slag, filter, and purify to obtain the purified liquid;

[0025] 2) Grind mica powder, titanium dioxide, calcined talc, calci...

Embodiment 2

[0030] An insulating ceramic for high-voltage transmission lines, comprising the following raw materials in parts by weight: 22 parts of mica powder, 11 parts of titanium dioxide, 6 parts of calcite, 6 parts of calcite, 17 parts of aluminum oxide, 6 parts of cobalt oxide, and 14 parts of calcium carbonate , 14 parts of barium carbonate, 4.5 parts of silicon dioxide, 18 parts of rhubarb, 19 parts of gum arabic, and 9 parts of gloss agent.

[0031] Wherein, the gloss agent is formed by mixing nonylphenol polyoxyethylene ether, nonylphenol polyoxyethylene ether sulfonate, and sodium naphthalenesulfonate in a weight ratio of 1:1:1.

[0032] In this embodiment, the preparation method of the insulating ceramics for high-voltage transmission lines, the steps are as follows:

[0033] 1) after crushing the ground root, add 90% ethanol solution with a concentration of 4 times by weight, stir evenly, seal and store at room temperature for 12 hours, remove slag, filter, and purify to obta...

Embodiment 3

[0039] An insulating ceramic for high-voltage transmission lines, comprising the following raw materials in parts by weight: 25 parts of mica powder, 12 parts of titanium dioxide, 8 parts of burnt talc, 8 parts of calcite, 20 parts of alumina, 8 parts of cobalt oxide, and 12 parts of calcium carbonate , 13 parts of barium carbonate, 4 parts of silicon dioxide, 15 parts of rhubarb, 17 parts of gum arabic, and 8 parts of gloss agent.

[0040] Wherein, the gloss agent is formed by mixing nonylphenol polyoxyethylene ether, nonylphenol polyoxyethylene ether sulfonate, and sodium naphthalenesulfonate in a weight ratio of 1:2:1. .

[0041] In this embodiment, the preparation method of the insulating ceramics for high-voltage transmission lines, the steps are as follows:

[0042] 1) after crushing the ground root, add 90% ethanol solution with a concentration of 4 times by weight, stir evenly, seal and store at room temperature for 12 hours, remove slag, filter, and purify to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com