100% substituted rate recycled aggregate concrete with low slump loss

A technology of slump loss and recycled aggregate, applied in sustainable waste treatment, solid waste management, climate sustainability, etc. The effect of promoting flow properties and enhancing interfacial strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The concrete mix ratio using ordinary recycled aggregate is shown in Table 1-1:

[0025] Table 1-1 Concrete mix ratio using ordinary recycled aggregate (kg / m 3 )

[0026] water

P.O42.5 cement

Granulated blast furnace slag powder

yellow sand

recycled coarse aggregate

Dosage of superplasticizer

210

190

70

90

850

1050

3.7

[0027] The working performance and mechanical properties of concrete using ordinary recycled aggregates are measured as shown in Table 1-2:

[0028] Table 1-2 Work performance and mechanical properties of ordinary recycled aggregate concrete

[0029]

Embodiment 2

[0031] The mix ratio of gel-treated recycled aggregate concrete is shown in Table 2-1:

[0032] Table 2-1 Mixing ratio of gel-treated recycled aggregate concrete (kg / m 3 )

[0033] water

P.O42.5 cement

Granulated blast furnace slag powder

yellow sand

Gel-treated recycled coarse aggregate

Dosage of superplasticizer

210

190

70

90

850

1050

3.7

[0034] The difference from Example 1 is that the ordinary recycled coarse aggregate is replaced by gel-treated recycled coarse aggregate, and other steps and parameters are the same as in Example 1.

[0035] The measured working and mechanical properties of the gel-treated recycled aggregate concrete are shown in Table 2-2:

[0036] Table 2-2 Workability and mechanical properties of gel-treated recycled aggregate concrete

[0037]

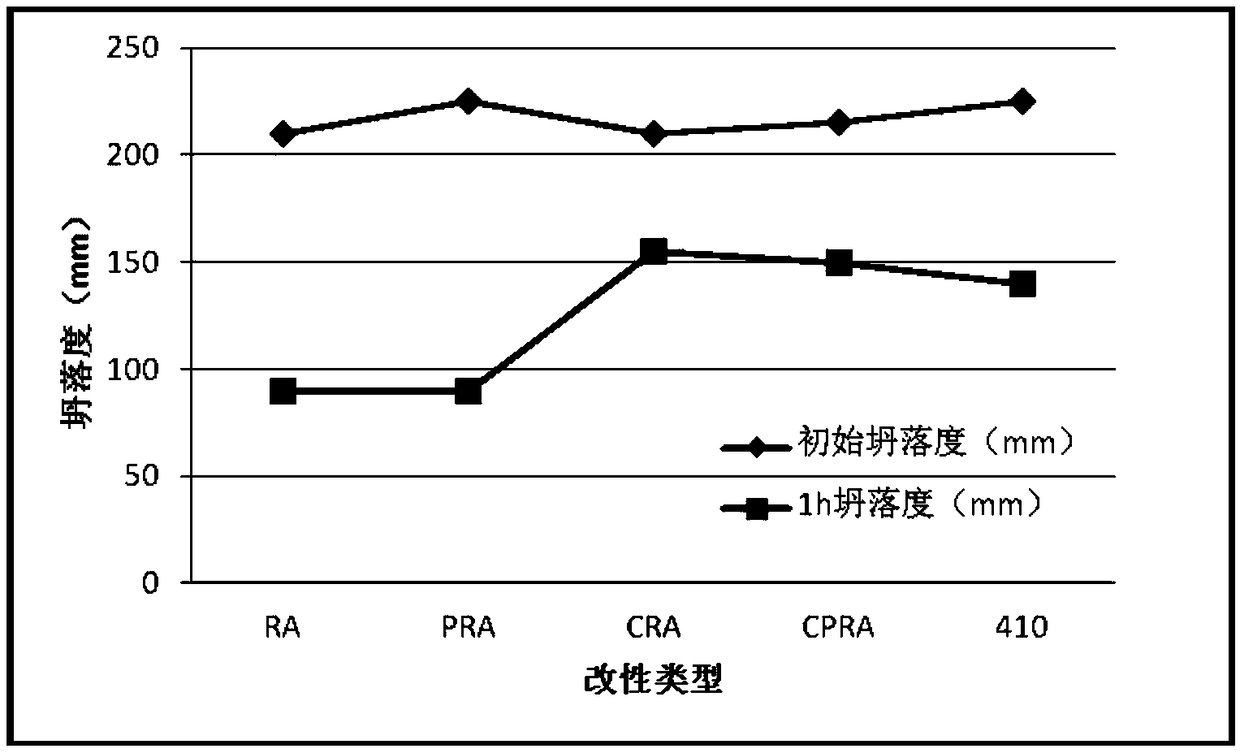

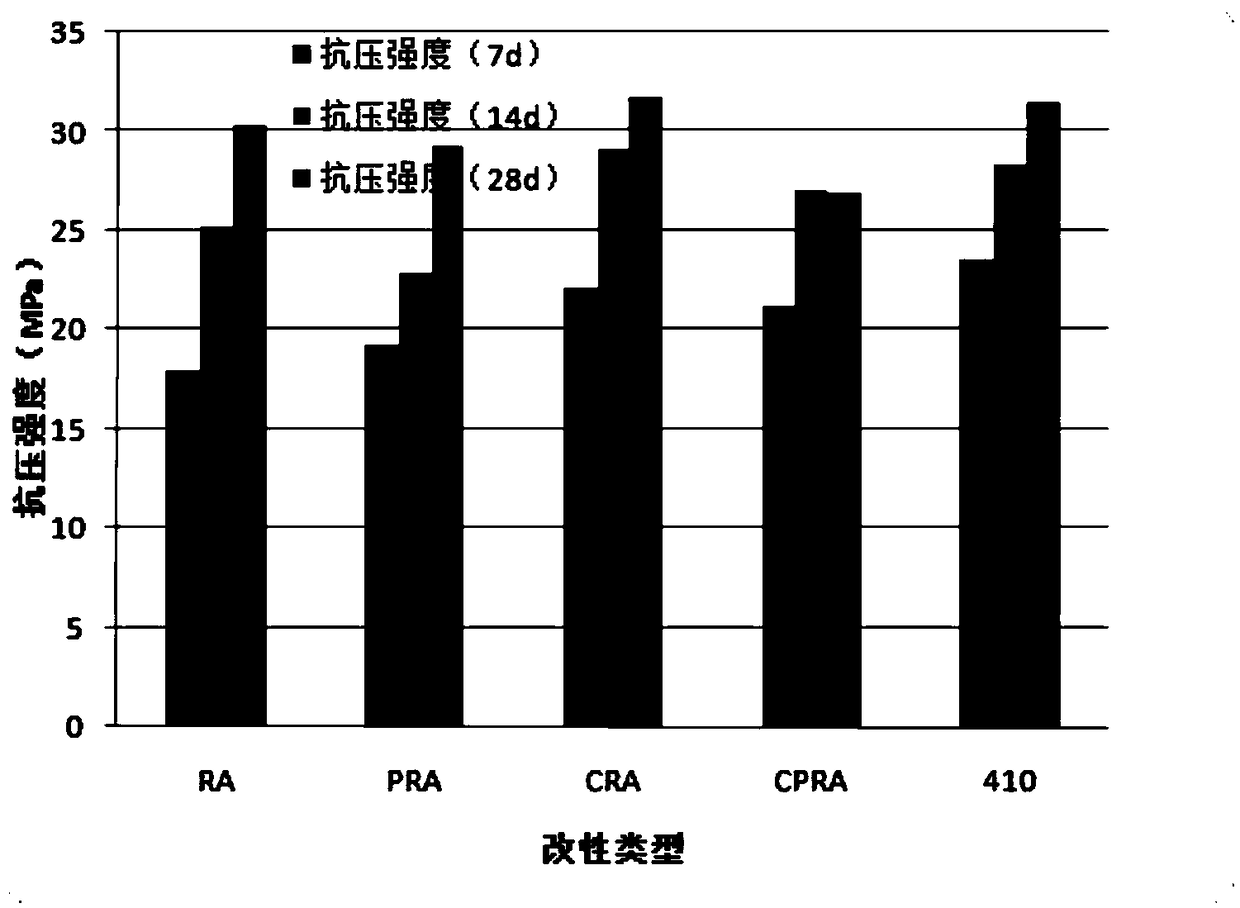

[0038] Its slump diagram is shown in figure 1 , the schematic diagram of its compressive strength is shown in figure 2 .

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com